What is a Woodruff Key?

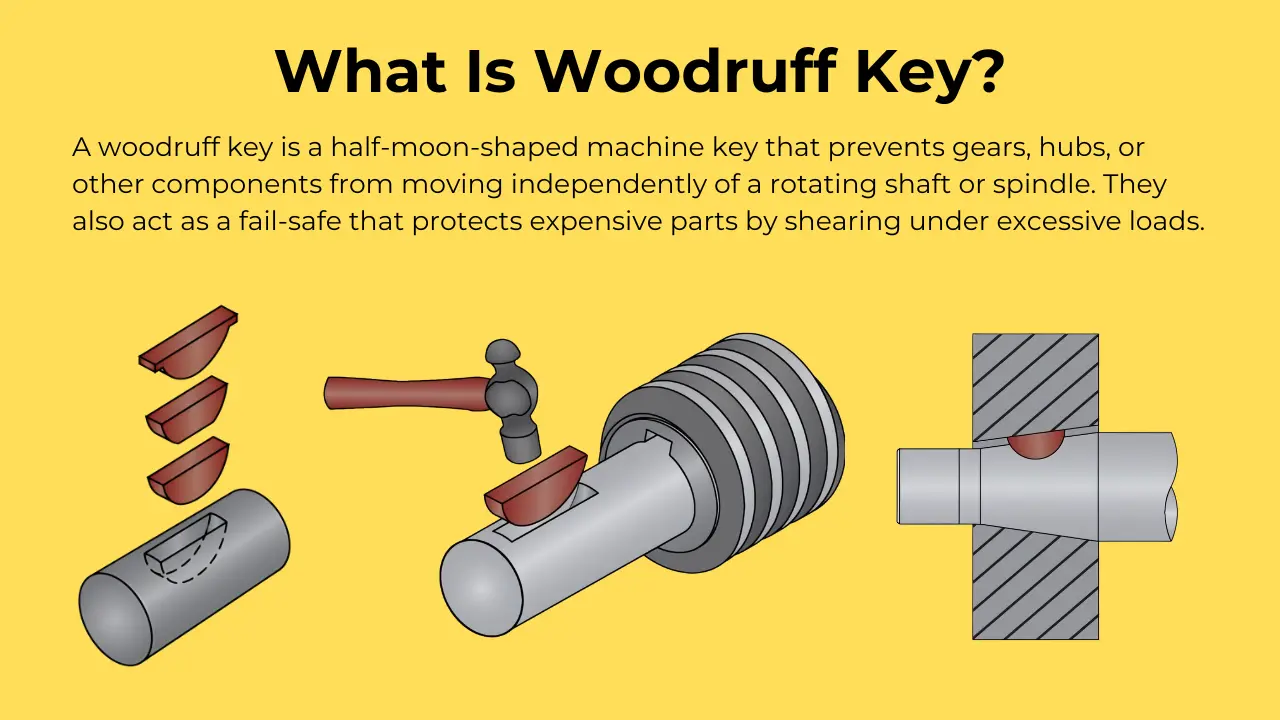

A Woodruff key is a distinctive, half-moon-shaped machine key designed to prevent gears, hubs, or similar components from rotating independently of the shaft or spindle to which they are mounted.

One of its key advantages lies in its function as a mechanical fail-safe; under excessive load, the Woodruff key is engineered to shear, thereby protecting more costly components from damage.

The unique crescent shape of the Woodruff key allows it to fit more deeply into the shaft, minimizing the risk of the key rolling out of its groove during operation. This semi-circular disc is installed in a precisely machined recess within the shaft, typically created with a Woodruff keyway cutter.

These keys are most commonly utilized in machine tools and automotive shafts with diameters ranging from approximately 6 mm to 60 mm (¼ inch to 2½ inches).

The shaft’s keyway takes the form of a semi-circular pocket, while the mating part features a corresponding longitudinal slot. This arrangement not only secures the two components together but also enhances concentricity between the shaft and the mounted part an essential consideration for applications involving high rotational speeds.

Manufacturing the Woodruff key’s seating is straightforward: a circular Woodruff cutter can plunge-cut the segment directly, eliminating the need for reliefs. One notable benefit is that this method avoids milling near shaft shoulders, where stress concentrations and issues with concentricity might otherwise arise.

A precisely fitted Woodruff key and keyway significantly reduce play between parts and help distribute stresses more evenly, contributing to increased reliability in mechanical assemblies.

The invention of the Woodruff key is credited to William N. Woodruff of Hartford, Connecticut, who received the John Scott Medal from the Franklin Institute in 1888 in recognition of his contribution. His innovation featured a design where a portion of the key remains exposed, effectively locking the mounted part against rotation.

While the presence of a Woodruff key does introduce a degree of shaft weakening, it has minimal tendency to overturn in use. For applications where loads are lighter and the cost of cutting a keyway may not be justified, alternatives such as round keys or flat (hollow saddle) keys can be considered.

It is important to note that Woodruff keys are relatively short and, as a result, are not suited for transmitting heavy torque or for use with wide-faced gears or multi-groove V-belt pulleys.

In scenarios where higher load transmission is required, the installation of multiple Woodruff keys in line is possible, but this approach tends to be costly and can complicate assembly.

For these reasons, Woodruff keys are most often reserved for light-duty applications and for mounting taper-bored components onto tapered shaft ends.

Why use a woodruff key?

One of the primary benefits of the Woodruff key lies in its design, which avoids the need for milling near shaft shoulders. This is crucial because milling close to these areas can introduce stress concentrations and negatively impact concentricity—issues that become particularly significant during high-speed operation.

Another practical aspect of the Woodruff key is its ability to rotate slightly within its circular recess. This self-adjusting feature allows it to accommodate any taper in the mating hub during assembly, making installation easier. However, because of this same characteristic, the Woodruff key cannot function as a feather key; attempting to use it as such would likely result in jamming.

In terms of usage, Woodruff keys are frequently found in machine tools, as well as in automotive applications such as the connection between the flywheel and crankshaft in small internal combustion engines. In these cases, the secure drive relies heavily on the fit between the shaft and the conically bored flywheel hub.

There’s also a practical maintenance advantage: if a Woodruff key becomes stuck in the shaft, it can typically be dislodged with a sharp hammer blow. The circular profile helps to eject the key from its slot, which is much simpler than the removal process for a standard key, where extraction must occur axially or by pulling.

Common areas where you’ll encounter Woodruff keys include machine tools, various automotive mechanisms, snowblowers, and marine propeller assemblies.

How does a Woodruff Key Work?

When you install a woodruff key, you’ll notice that its long, flat side actually sticks out slightly above the surface of the shaft it’s set into. This design isn’t accidental—it’s what makes the key effective.

As soon as you press a hub, gear, or any other compatible part onto the shaft, that raised edge of the woodruff key fits right into a slot on the mating component. The result? The key essentially acts as a lock, ensuring both parts are securely joined and rotate together without slipping.

Installing A Woodruff Key:

When you’re installing a woodruff key, the first step is to press it firmly into the half-moon shaped groove that’s been machined into the shaft. It’s important to make sure that the flat, upper surface of the key sits parallel to the shaft itself; this alignment makes a difference later on.

One thing to keep in mind during installation: woodruff keys have a bit of a reputation for slipping out of their groove just as you’re trying to fit the mating part over them. It’s a surprisingly common hiccup, and it can definitely make the process more frustrating than you’d expect.

Taking your time with this step often helps, but it’s something that just comes with the territory when working with these keys.

How To Keep a Woodruff Key in Place?

When you’re working with a woodruff key, one of the most important steps is making sure it stays put during assembly. Start by pressing the key firmly into its seat—these keys are manufactured with pretty tight tolerances, so they should fit snugly right from the start.

Usually, you can use a hammer or mallet to gently tap the flat, exposed side of the key. This helps settle the key into place, ensuring it’s not going anywhere. Even after it’s seated, you’ll notice part of the key will still stick up above the shaft, and that’s intentional—it’s what allows the hub or gear to lock on securely.

But if you find the key slipping out or falling during installation, it’s a sign that the key doesn’t match the groove as it should. In that case, you’re probably dealing with a key that’s just a bit too small for the slot.

Selecting The Right Woodruff Key

When working through the design phase of any application, it’s worth taking a closer look at the various features that come with a Woodruff key.

Designers should pay particular attention to factors like the specific type of key being used, the material chosen for the key, and the kind of finish applied. Each of these elements can have a real impact on the performance and reliability of the final assembly.

What Are the Different Types of Woodruff Keys?

Among woodruff keys, the two designs you’ll encounter most often are the full radius and the flat bottom types. While they essentially serve the same purpose, the choice between them can come down to the specific requirements of your project.

One thing to keep in mind: both the radius and flat bottom woodruff keys are considered standard parts. Manufacturers typically choose which version to include when shipping, so unless you specify your preference, you might receive either type. If your application truly calls for one over the other, it’s always best to clearly state that upfront with your supplier.

- Full radius woodruff keys are designed as a complete half-circle, which means they fit snugly and make total contact with the groove seat. The catch, though, is that the groove itself needs to be machined with precision—otherwise, there’s a good chance the key will press against the bottom of the seat. When that happens, the key can end up sticking out higher than you’d want, potentially causing fitment issues.

- On the other hand, flat bottom woodruff keys take a slightly different approach. While their overall profile remains similar to the standard version, their bottoms are shaved flat. This simple modification goes a long way in preventing interference at the base of the groove. As a result, the key can sit fully down in its seat, and you’re less likely to run into problems with the key protruding too much.

- Then there’s the Hi‑Pro key, which puts its own twist on the woodruff design. This variant keeps the full radius shape but adds what are known as “feet.” Once installed, these feet extend out over the shaft’s face, which helps keep the key stable and stops it from rocking in its rounded seat.

Woodruff Key Materials

Woodruff keys are commonly manufactured from carbon steel, alloy steel, or stainless steel. While both carbon and alloy steel varieties are known for their strength and durability, they do require a protective coating or plating to guard against corrosion over time.

On the other hand, stainless steel Woodruff keys naturally offer superior resistance to rust and corrosion, though they tend to be somewhat less robust compared to their carbon and alloy steel counterparts.

Woodruff Key Finishes

Woodruff keys are offered in a variety of finishes, such as plain, clear zinc, yellow zinc, and passivated. Each of these finishes serves a specific purpose, whether it’s to enhance durability, improve corrosion resistance, or simply meet aesthetic requirements.

- Plain Finish: Woodruff keys made from carbon steel and alloy steel are often supplied with a plain finish. This is generally chosen for applications where the keys are not expected to face harsh or corrosive environments. It’s a straightforward and cost-effective option that works well when corrosion resistance isn’t a primary concern.

- Zinc Plating: When extra protection is needed, carbon steel woodruff keys can be coated with a layer of zinc, available in either a yellow or clear finish. This zinc plating provides noticeably better resistance to corrosion compared to uncoated keys, making it a good fit for situations where moisture or other corrosive factors might be present.

- Passivated Finish: Stainless steel woodruff keys can undergo a process called passivation, where a thin oxide layer forms on the surface. This added microfilm boosts the material’s already strong resistance to corrosion. Passivation is commonly used to give stainless steel parts an extra measure of durability, especially in environments where corrosion is a concern.

Advantages of Woodruff Key

- This key can be easily adjusted, making it convenient for different applications.

- It’s designed to fit any taper present in the hub keyway, which adds flexibility during assembly.

- Because the key and the keyway match so precisely, there’s much less play between them. This snug fit helps reduce stress concentrations and actually boosts the reliability of the entire setup.

- One big advantage is that it does away with the need for milling near the shaft shoulders. That’s important, since unnecessary milling in those areas could otherwise cause stress concentrations or even affect concentricity.

- This kind of key becomes especially significant when you’re dealing with high-speed operation, where reliability is critical.

- When used at the ends of shafts, its deeper seating in the shaft helps prevent it from overturning within its keyway. This little detail really helps with stability and long-term performance.

Disadvantages of Woodruff key

- The depth of the keyway weakens the shaft.

- It cannot be used as a feather.

- Difficult to install and short, and

- It can’t carry too much load

FAQs

What is a woodruff key used for?

Woodruff keys are semi-circular discs used to connect machine parts to rotating shafts and spindles. They serve to stop gears or other machine parts from moving independently from the rotating shaft and are often installed into the recessed key seats cut into the said shafts.

What is the difference between a square key and a woodruff key?

Parallel square and rectangular keys are normally side fitting with top clearance and are usually retained in the shaft rather, more securely than in the hub. A Woodruff Key is a half moon shaped key that is inserted into a curved slot in the shaft.

What is the strength of a woodruff key?

Woodruff Keys are stocked as standard in C45+C key steel, with a minimum tensile strength of 60Kg/mm².

How did woodruff key get its name?

The term “woodruff key” , in relation to engineering comes from the Woodruff Manufacturing Company of Conneticut US.

Should woodruff key be tight?

To keep a woodruff key in place while installing a mating component, ensure that it is situated tightly in the key seat.

What are the advantages of a woodruff key?

Adjusts to any taper present in mating piece or shaft. Ideal for high speed rotating assemblies. Eliminates milling near shaft shoulders reducing stress concentrations at the shaft end. Deeper seat in the shaft reduces risk of rolling out of key seat.