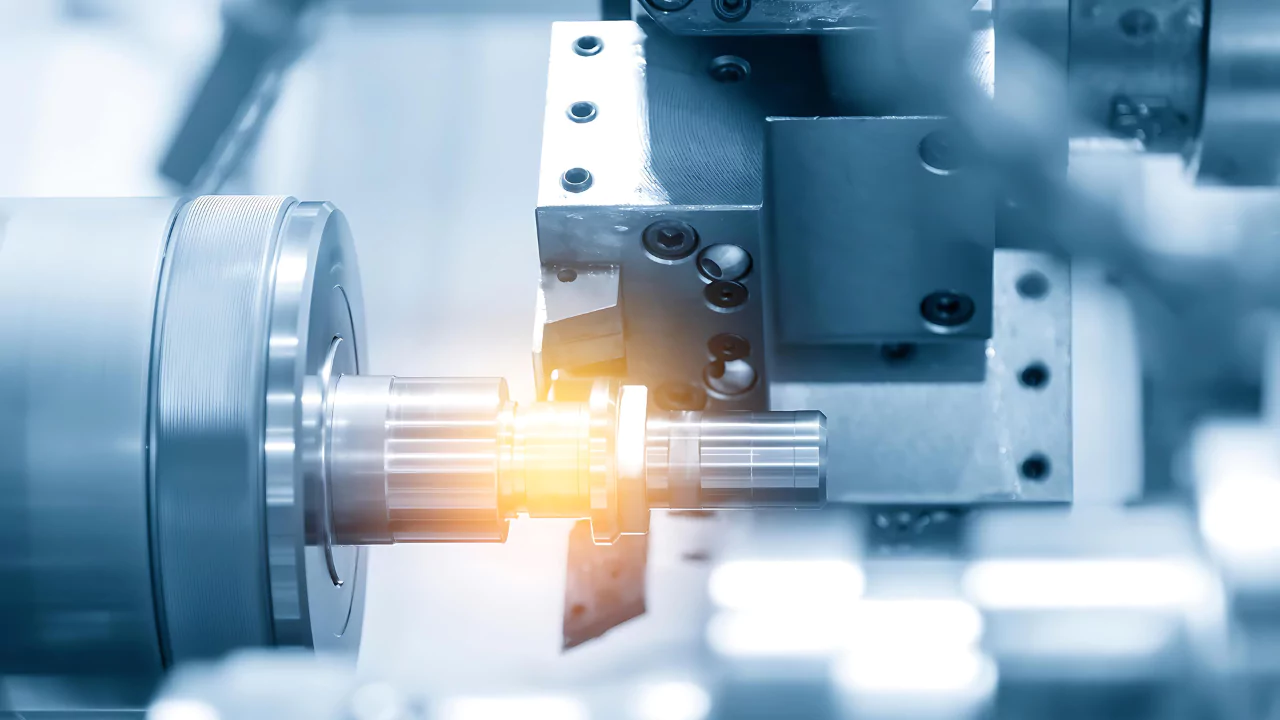

What is turning? Turning is a machining process where a lathe is used to rotate the metal while a cutting tool moves in a linear motion to remove metal along the diameter, creating a cylindrical shape. The cutting tool can be angled differently to create different forms. It can be done manually or with a CNC turning machine. CNC machining is generally used when part measurements must be very exact.

What is Turning?

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

Usually the term “turning” is reserved for the generation of external surfaces by this cutting action, whereas this same essential cutting action, when applied to internal surfaces, is called “boring“.

Thus the phrase “turning and boring” categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called “facing”, and maybe lumped into either category as a subset.

Turning can be done manually, with a conventional lathe that often requires continuous operator supervision, or with an automated lathe that does not. Today the most common type of this automation is computer numerical control, better known as CNC.

When turning, the workpiece (e.g., wood, metal, plastic, or stone) is rotated and a cutting tool is moved in 1, 2 or 3 axes of motion in order to create precise diameters and depths. Turning can be done either on the outside of the cylinder or on the inside (also known as drilling) to produce tubular components with various geometries.

Although quite rare today, early lathes could even be used to make complex geometric figures, even the Platonic solids; although since the advent of the CNC it has become uncommon to use non-computerized toolpath control for this purpose.

The turning processes are typically carried out on a lathe, which is considered to be the oldest of the machine tools and can be of various types, such as straight turning, taper turning, profiling, or external grooving.

With this turning process, different material shapes such as straight, conical, curved, or grooved workpieces can be produced. When turning, simple single-point cutting is generally used. Each group of workpiece materials has an optimal set of tool angles that have been developed over the years.

The bits of waste metal from turning operations are known as chips (North America), or swarf (Britain). In some areas, they may be known as turnings.

Turning Process

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool.

The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools.

The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

Turning is used to produce rotational, typically axis-symmetric, parts that have many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated completely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom-designed shafts and fasteners.

Turning is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that turning can offer, it is ideal for adding precision rotational features to a part whose basic shape has already been formed.

Turning operations

Turning is the most common lathe machining operation. During the turning process, a cutting tool removes material from the outer diameter of a rotating workpiece. The main objective of turning is to reduce the workpiece diameter to the desired dimension. There are two types of turning operations, rough and finish.

A variety of operations can be performed on the workpiece during the process cycle to obtain the desired shape of the part. These operations can be classified as external or internal.

External operations change the outside diameter of the part, while internal operations change the inside diameter. The following operations are each defined by the type of cutter used and the path this cutter takes to remove material from the workpiece.

Turning specific operations (External)

- Turning. A single-point turning tool moves axially, along the side of the workpiece, removing material to form different features, including steps, tapers, chamfers, and contours. These features are typically machined at a small radial depth of cut and multiple passes are made until the end diameter is reached.

- Tapered turning. Tapered turning produces a cylindrical shape that gradually decreases in diameter from one end to the other.

- Hard Turning. Hard turning is a type of turning done on materials with a Rockwell C hardness greater than 45. It is typically performed after the workpiece is heat treated. The process is intended to replace or limit traditional grinding operations. Hard turning, when applied for purely stock removal purposes, competes favorably with rough grinding. However, when it is applied for finishing where form and dimension are critical, grinding is superior.

- Facing. A single-point turning tool moves radially, along the end of the workpiece, removing a thin layer of material to provide a smooth flat surface. The depth of the face, typically very small, may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

- Parting. Similar to the grooving, a single-point cut-off tool moves radially, into the side of the workpiece, and continues until the center or inner diameter of the workpiece is reached, thus parting or cutting off a section of the workpiece.

- Grooving. A single-point turning tool moves radially, into the side of the workpiece, cutting a groove equal in width to the cutting tool. Multiple cuts can be made to form grooves larger than the tool width and special form tools can be used to create grooves of varying geometries.

Non-specific operations (Internal)

- Boring. A boring tool enters the workpiece axially and cuts along an internal surface to form different features, such as steps, tapers, chamfers, and contours. The boring tool is a single-point cutting tool, which can be set to cut the desired diameter by using an adjustable boring head. Boring is commonly performed after drilling a hole in order to enlarge the diameter or obtain more precise dimensions.

- Drilling. It is used to remove material from the inside of a workpiece. This process utilizes standard drill bits held stationary in the tail stock or tool turret of the lathe. The process can be done by separately available drilling machines.

- Knurling. The cutting of a serrated pattern onto the surface of a part to use as a hand grip or as a visual enhancement using a special-purpose knurling tool.

- Reaming. The sizing operation removes a small amount of metal from a hole already drilled. It is done for making internal holes of very accurate diameters. For example, a 6mm hole is made by drilling with a 5.98 mm drill bit and then reamed to accurate dimensions.

- Threading. A single-point threading tool, typically with a 60-degree pointed nose, moves axially, along the side of the workpiece, cutting threads into the outer surface. The threads can be cut to a specified length and pitch and may require multiple passes to be formed.

- Polygonal turning. In which non-circular forms are machined without interrupting the rotation of the raw material.

Cutting parameters

When turning, the speed and motion of the cutting tool are specified by several parameters. These parameters are selected for each operation based on workpiece material, tool material, tool size, and more.

- Cutting feed – The distance that the cutting tool or workpiece advances during one revolution of the spindle, measured in inches per revolution (IPR). In some operations, the tool feeds into the workpiece and in others, the workpiece feeds into the tool. For a multi-point tool, the cutting feed is also equal to the feed per tooth, measured in inches per tooth (IPT), multiplied by the number of teeth on the cutting tool.

- Cutting speed – The speed of the workpiece surface relative to the edge of the cutting tool during a cut, measured in surface feet per minute (SFM).

- Spindle speed – The rotational speed of the spindle and the workpiece in revolutions per minute (RPM). The spindle speed is equal to the cutting speed divided by the circumference of the workpiece where the cut is being made. In order to maintain a constant cutting speed, the spindle speed must vary based on the diameter of the cut. If the spindle speed is held constant, then the cutting speed will vary.

- Feed rate – The speed of the cutting tool’s movement relative to the workpiece as the tool makes a cut. The feed rate is measured in inches per minute (IPM) and is the product of the cutting feed (IPR) and the spindle speed (RPM).

- Axial depth of cut – The depth of the tool along the axis of the workpiece as it makes a cut, as in a facing operation. A large axial depth of cut will require a low feed rate, or else it will result in a high load on the tool and reduce the tool’s life. Therefore, a feature is typically machined in several passes as the tool moves to the specified axial depth of cut for each pass.

- Radial depth of cut – The depth of the tool along the radius of the workpiece as it makes a cut, as in a turning or boring operation. A large radial depth of cut will require a low feed rate, or else it will result in a high load on the tool and reduce the tool’s life. Therefore, a feature is often machined in several steps as the tool moves over at the radial depth of cut.

Tooling

The various angles, shapes, and sizes of a single-point cutting tool are directly related to the resulting surface of a workpiece during machining operations. There are different types of angles such as rake angle, side rake angle, cutting edge angle, relief angle, and nose radius that exists and can be different in relation to the workpiece.

There are also many shapes of single-point cutting tools such as V-shaped and square. A special tool holder is usually used to hold the cutting tool in place during operation.

FAQs

What is a turning operation?

Turning is a machining process where a lathe is used to rotate the metal while a cutting tool moves in a linear motion to remove metal along the diameter, creating a cylindrical shape. The cutting tool can be angled differently to create different forms. It can be done manually or with a CNC turning machine.

What is the principle of turning?

Turning operates on a simple yet effective principle: The workpiece is rotated at high speed while a single point cutting tool traverses along the workpiece’s surface, cutting off a thin layer of material. The cutting action takes place at the point where the tool’s cutting edge meets the workpiece.

What are the stages of turning?

Most importantly, in each human life cycle, society goes through four major turning events as each generation passes from one phase to the next. These four phases are High, Awakening, Unraveling and Crisis.

What is the difference between CNC and turning?

CNC milling processes involve the material being held in place while the cutting tools rotate around it. CNC turning, on the other hand, requires the tools to maintain in the same place while the material is rotated at speed to create the exact shape.

What is the step turning method?

Step turning creates two surfaces with an abrupt change in diameters between them. The final feature resembles a step.