What is Reamer?

A reamer is a rotary cutting tool, typically cylindrical or sometimes conical, intended for finishing and increasing the size of a hole that is already drilled, bored, or cored. Reamers are not intended to create a hole from scratch, but instead refine an existing one, either further improving the size of the hole and/or the smoothness of the sides.

There are many different kinds of reamers. Machine reamers are for use with machine tools, such as drill presses, lathes, or screw machines. If you have ever needed to make a hole a bit more accurate in a workshop or industrial environment – these are the tools you would be reaching for.

Precision reamers are for when accuracy is important. Although they take a previously formed hole and enlarge it, they do so accurately to leave a smooth, clean finish. Non-precision reamers are useful for general purposes, such as enlarging a hole or getting rid of rough edges and burrs.

The act of using a reamer is called reaming. Like many other tools, reamers can be designed for hand use, or for machines, depending on the intended use – you will have reamers for hand tools to reamers for milling machines and drill presses.

Construction

A reamer often has one or more series of parallel (either straight or helical) cutting edges that are oriented along the length of the cylindrical body.

Each cutting edge is not only ground straight, there is some angularity and an undercut below the cutting edge. These minor preferences have a substantial influence on the performance of the tool.

For reamers, there are trade-offs to be made. The cutting edges should be hard enough to withstand metal removal over time, but the reamer also has to be tough enough to tolerate the normal forces of the operation.

Reamers are not tools to remove substantial amounts of metal – they are for the finishing passes that will make that hole cleaner or more precise. Again, being consistent in this operation, extends the reamer wear life and gives a better finish in desired tolerance limits.

The spirals on a reamer can go either way (clockwise and counter-clockwise). This is more important than you might think! For example, if taking a tapered hand reamer with a clockwise spiral, the tool will grab into the work piece as you turn it. This can cause the reamer to wedge and possibly break or damage the workpiece.

That is the reason why even for reamers, counter-clockwise spiral is preferred (even if they are clockwise during hand turning!).

There are different shank types based on the usage of the reamer. In production machines you will likely run into a standard taper, like Morse or Brown & Sharpe, or simply a straight round shank that will be either held in a collet, or held in the chuck by a set screw if it has a flat side.

Conversely, a reamer designed for manual use will likely have a square end so it can turn with the same wrench as with a tap when you are cutting screw threads.

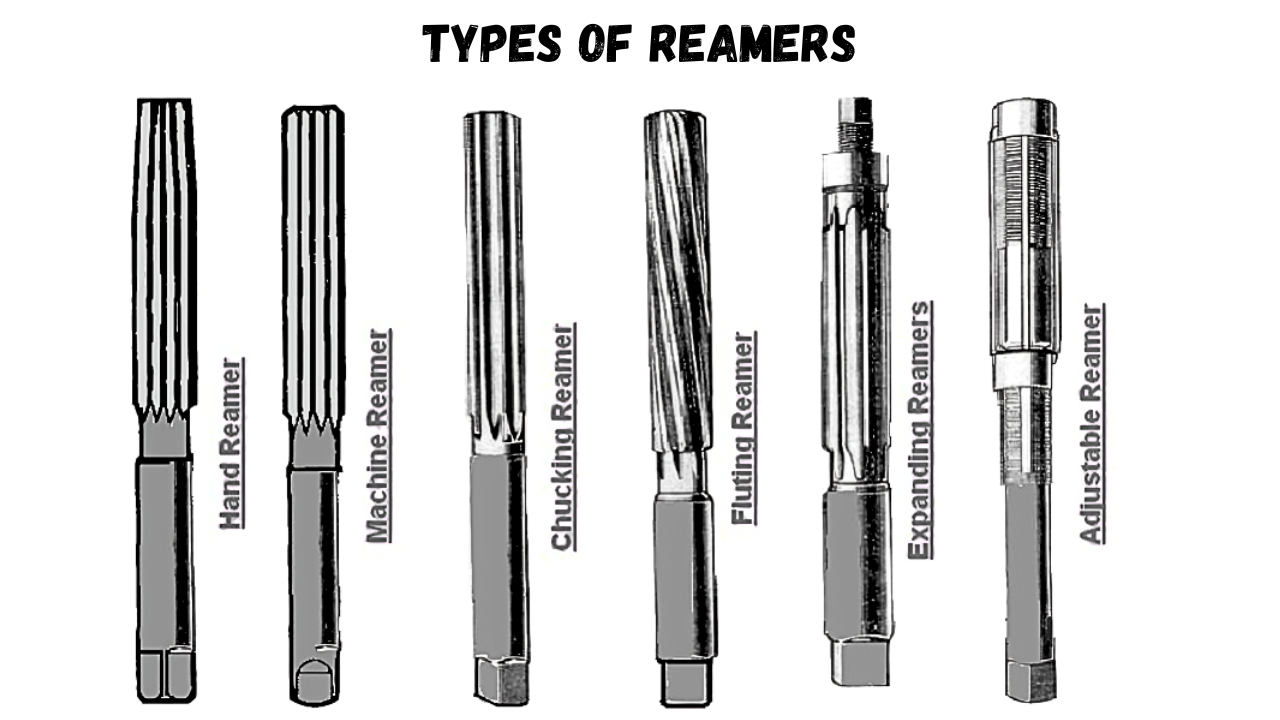

Types Of Reamers

The following are the main types of reamer tools:

- Chucking Reamer.

- Adjustable hand reamer.

- Straight reamer.

- Rose reamer.

- Shell reamer.

- Tapered reamer

- Combination reamer.

- Tapered reamer (non-precision)

1. Chucking Reamer

Most commonly used for finishing holes on equipment such as lathes, drill presses and screw machines are known as chucking reamers or machine reamers. Chucking reamers are really popular and easy to obtain as they leave a very smooth and accurate finish.

You can obtain chucking reamers in a variety of flutes and cuts, for example, right-hand cut, left-hand spiral, or straight flute depending on the workflow needed in machining operations.

Chucking reamers come with a straight shank or with a Morse taper shank which allows for versatility based on the machine setup.

2. Adjustable hand reamer

Adjustable hand reamers are available in various specifications to fit a limited number of hole sizes, each generally specified with a letter that refers to the size of hole that is adjusted.

Replaceable blades are fitted into tapered grooves; the cutting diameter can be set exactly by loosening or tightening the restraining nuts on each end.

However, due to the lack of spiral flutes, adjustable hand reamers are intended for light-duty work, where only limited material needs to be removed each time the judgment opens up the cutting diameter. The absence of spiraling means they tend to chatter, which limits their cutting aggressiveness.

It should also be noted that adjustable hand reamers are only made to be used in holes that have not been damaged or compromised. In holes with an axial split, like split bushings or clamping situations, each straight-edged tooth will typically fall into the gap in turn.

As a result, the other cutting edges are pulled away from the work material, resulting in uneven cutting and increased chatter. Not only will this show marks on the work, but it will also prevent the reamer from sizing the hole accurately and defeats the purpose of the tool.

3. Straight reamer

A straight reamer is used usually where only a minor increase in the size of a hole is required. At the tip of the reamer, a tapered section is present and the distance and degree of the taper will vary among the types of reamers employed.

The tapered section allows the tool to automatically align itself when it is guided into the already drilled hole, providing a more accurate fit. The remainder of the reamer has a diameter of the same size for its whole length, allowing for a parallel finish as it reaches its intended diameter.

4. Hand reamer

When observing hand reamers, one will notice that hand reamers have much longer tapers (or lead-in) at the front than machine reamers.

The taper section serves a purpose—not just decorative; it serves as a reference for a correct start when using a reamer by hand, without the assistance of the power of a machine, and will make the task functional.

With the longer taper, a hand reamer is able to set itself correctly at the start so that it is encouraged to start straight and also has less chance of breaking the tool itself. The flutes may also be either straight or spiral, giving some discretion on the the job.

5. Machine reamer

Machine reamers only incorporate a minimal lead-in because the reamer and workpiece are aligned by the machine, ensuring there is no chance of the tool drifting.

Another benefit to using a machine to ream is that a machine can maintain a constant cutting force, which means the reamer begins cutting as soon as it comes into contact with the workpiece.

Although spiral flutes are ideal as they remove swarf away from the hole directly, straight flutes are also widely used in reamers. For most reaming operations, there is not a lot of swarf produced, and complete chip removal is not very important anyway.

6. Rose reamer

A rose reamer is defined as having no peripheral relief and using a slight taper on the front end to reduce or limit the risk of binding during operation. A rose reamer is often used as a softening reamer during secondary operations.

7. Shell reamer

Shell reamers are used for finishing the internal surfaces of bearings and other similar parts. The flutes extending down the shell reamer help finish surfaces smooth and accurately.

8. Tapered reamer

A precision tapered reamer has a very narrow purpose in life – to make a tapered hole for a tapered pin. A tapered pin is uniquely distinctive in that it has a small, shallow angle, which allows it to lock itself into place.

So once the taper pin is pushed into the reamed hole, it can be so snug that pushing or pulling it out, like pushing marine caulking out of a tube, requires some demolition, usually applied with a hammer and punch.

Taper pins have a straightforward numbered system for their sizes. So if you use a No. 4 reamer, you will need to use a No. 4 taper pin – it’s that simple.

You will find these precision joints being used extensively in the construction of aircraft. They are generally used for joining sections of wings, especially in sailplanes, where structural integrity matters.

As an aircraft is serviced and maintained throughout the years, it is quite common for these joints to be re-reamed during that process to get to a fresh fit. Each time that happens, it is safe to assume that a slightly larger pin is providing wear compensation, maintaining a snug and reliable connection for the aircraft’s service life.

9. Morse taper reamer

A Morse taper reamer is a hand tool used for finishing Morse Taper sleeves. I used the term sleeves, as it relates to what the taper sleeves do in a much larger context – securing cutting tools, or tool holders in the spindle of machines that have a drill, milling machine, or similar machines.

Suffice it to say that all machine shops require Morse taper sleeves. The reamer I am referring to is a finishing reamer, or the reamer referred to as the finishing reamer provides the last pass to create a smooth and precise fit.

In addition, there is also a roughing reamer. The difference between a finishing reamer and a roughing reamer is the serrations on the flutes. These notches are part of the larger serrations to help break apart thick chips that are formed during a more aggressive, heavy-duty cut.

10. Combination reamer

Combination reamers are specially-designed tools with more than one cutting surface, each configured to match the variations in internal diameters in a part. The strength of this tool is that it can do multiple cutting operations at the same time.

By using a combination reamer, machinists can also reduce the number of turret changes required in production. This takes away operator variability, and helps in maintaining a more accurate control of depth, diameter, and positioning on the holes being machined.

In practice, combination reamers are most commonly used in screw machines or second-operation lathes. They are not practical for CNC machines because with CNCs, it is a simple matter of generating the proper G-code to make complex internal profiles. Therefore, the value of adding multiple cutting steps to one tool is much less significant.

11. Tapered reamer (non-precision)

A tapered reamer is a versatile tool often used for burr removal from drilled holes or for minor enlargements of openings. It has a simple construction, where its body tapers down to a point. The body is usually up to half an inch in diameter, and it has a crossbar, basically a rod, at the larger end to serve as a handle.

This tool is best suited to softer metals, e.g. aluminum, copper or mild steel, and are known colloquially as “maintenance reamer” because they represent the most commons tasks of regular deburring and enlarging holes, specifically of MRO activities.

There is also a hand reamer built into some Swiss Army knives. For example, in the electrician version, which includes a reamer for conduit preparation.

Applications of Reamer

The following are the applications of a reamer:

- A reamer is a rotary cutting tool used in metalworking.

- It is used to enlarge or finish an existing hole, whether it is drilled, bored, or cored, so that it has a smooth and correct size.

- Usually, reamers are used with drill presses and turret lathes.

- They are also used with screw-cutting machines. When a hole is finished nicely, the machine will finish the holes with a reamer.

FAQs.

What is the reamer used for?

A reamer tool is used to widen the size of a pre-existing hole in metal by a small amount to leave smooth sides – removing any burrs or rough edges. It’s a pointed round file with a tip that’s typically coated in diamond dust to create a hard, durable surface that’s great for filing.

What is the purpose of reaming?

Reaming is a sizing operation that removes a small amount of metal from a hole already drilled. It is done for two purposes: to bring holes to a more exact size and to improve the finish of an existing hole.

What are the three types of reamers?

1. Chucking Reamers are the most widely used reamer and commonly used in lathes to enlarge smooth holes.

2. Morse Taper Reamers are used to finish morse taper holes or sleeves.

3. Automotive Reamers are used to ream steel for car parts such as steering arms, ball joints, and tie rod ends in vehicles.

What is the difference between a reamer and a drill?

The rotary cutting tool used in reaming is known as a reamer. Like drill bits, reamers also remove material from the workpiece on which they are used. However, reamers remove significantly less material than drill bits. The primary purpose of reaming is simply to create smooth walls in an existing hole.

When should a reamer be used?

Reamer tools are ideal for those who are looking for a more precise hole, as they take the pre-drilled hole made by a drill bit and make it truly round and of an exact diameter size.

What are the disadvantages of a reamer?

Despite its benefits, reaming also has some disadvantages: Pre-Machined Holes Required: Reaming cannot create a hole; it can only enlarge and finish pre-drilled or pre-machined holes. Tool Wear: If not used correctly, there is a risk of tool breakage and wear.