What Is a Micrometer?

A micrometer is a precision measuring instrument capable of delivering exceptionally accurate readings, often to within a thousandth of an inch. This level of precision becomes crucial in situations where even the slightest gap or misalignment can create significant issues.

Commonly referred to as a micrometer screw gauge, this tool relies on a finely calibrated screw mechanism. It sees widespread use in mechanical engineering, machining, and related fields, where precise measurement of components is essential. Alongside other tools—like vernier calipers, dial calipers, and digital calipers—the micrometer plays a central role in metrology.

Typically, micrometers take the form of calipers, where two opposing ends are connected by a sturdy frame. One end houses the spindle—a screw machined to extremely tight tolerances—while the other features the anvil.

To take a measurement, the user places the object between the spindle and the anvil, then gently advances the spindle using the ratchet knob or thimble, stopping as soon as the object is held just firmly enough.

The utility of micrometers extends beyond the workshop. For example, they are adapted for use in telescopes and microscopes, allowing for accurate measurement of the apparent diameter of celestial bodies or microscopic samples.

It is worth noting that the micrometer’s application in astronomy dates back to the 17th century, with William Gascoigne, an English astronomer, credited for inventing a micrometer suitable for telescopes around 1638.

Micrometer Symbol

A micrometer, often referred to as a micron, is a metric unit of length that equals 0.001 millimeters, or approximately 0.000039 inches. The standard symbol for the micrometer is μm. This unit is particularly useful in fields that require precise measurement of very small dimensions, such as the thickness or diameter of microscopic entities, microorganisms, and colloidal particles, for example.

Parts of Micrometer

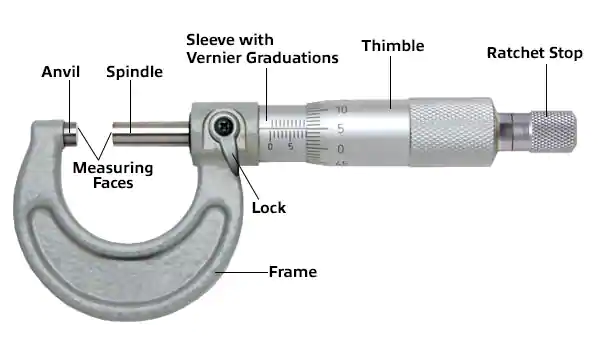

A micrometer is composed of:

- Frame: The frame, easily recognized by its characteristic C-shape, is designed to maintain a fixed relationship between the anvil and the barrel. Its substantial thickness isn’t arbitrary—this structure is necessary to limit any bending, expansion, or contraction that could compromise the accuracy of measurements. Because the frame is relatively heavy, it possesses significant thermal mass, which helps prevent noticeable warming from the user’s hand. Many models include insulating plastic plates to further reduce heat transfer from touch.

- Anvil: This is the polished surface that the spindle moves toward, serving as the point where the sample is held steady during measurement.

- Sleeve, barrel, or stock: This component remains stationary and displays the linear measurement scale, sometimes enhanced with vernier markings for greater precision. In certain designs, you’ll notice the scale marked on a snug, yet movable, cylindrical sleeve that fits over the fixed barrel. This arrangement allows for fine adjustments—such as zeroing the instrument—by shifting the sleeve slightly.

- Lock nut, lock-ring, or thimble lock: This refers to the knurled part (or occasionally a lever) that can be tightened to keep the spindle from moving, which is useful for temporarily holding a measurement in place.

- Screw: At the heart of the micrometer is the precision screw mechanism housed inside the barrel. This design feature even finds its way into the German name for the instrument, Messschraube, or “measuring screw.”

- Spindle: The spindle is the smooth, cylindrical part that advances toward the anvil as you rotate the thimble.

- Thimble: This is the section you turn with your thumb. It bears graduated markings to help the user read fine measurements as the spindle advances.

- Ratchet stop: Located at the end of the handle, the ratchet stop ensures the applied pressure remains consistent by slipping once a calibrated torque is reached, thereby safeguarding the measurement’s accuracy.

Types of Micrometers

There are several types of micrometers that are designed to measure different types of objects or spaces. Most micrometers are available in sets to accommodate measurements of varying size.

#1. Outside Micrometer

This particular type of micrometer is intended for gauging the external dimensions of objects, such as their outside diameter (OD). Its structure and operation are somewhat reminiscent of a C-clamp, opening and closing by means of a threaded screw mechanism.

When using a micrometer, the item to be measured is positioned between two components: the anvil, which remains fixed, and the spindle, which moves to secure the object in place. After gently tightening the spindle so the object is held firmly, you can read the measurement directly from the scale on the thimble, which acts as the rotating handle.

#2. Inside Micrometer

Whereas the outside micrometer is designed to measure the external diameter of an object, the inside micrometer serves the purpose of determining internal dimensions, such as the inside diameter (ID). The inside micrometer somewhat resembles a pen, featuring a central thimble that rotates.

When you turn the thimble, the micrometer gradually extends outward—much like how a curtain rod expands—until both ends make contact with the inner walls of the pipe or opening being measured. Once the tool is snug against both sides, you simply read the value indicated by the scale on the thimble to determine the internal measurement.

#3. Depth Micrometers

Although both inside and outside micrometers are designed to measure diameters—whether it’s the diameter of an object or the width of a hole—a depth micrometer serves a different purpose. Its main role is to determine the depth of features such as holes, recesses, or slots.

To achieve this, the depth micrometer has a flat base, which sits firmly on the reference surface at the top of the feature being measured.

Rising from this base, you’ll find the shaft, with the thimble mounted at the top. As you turn the thimble, a slender measuring rod extends downward from the shaft. The process is simple: continue rotating the thimble until the rod makes contact with the very bottom of the hole or slot.

Once the rod is resting against the base of the feature, you can take the reading by referencing the graduated markings on the thimble itself.

When Would I Use a Micrometer?

When precision matters most, the micrometer becomes an essential tool. Its design varies depending on what is being measured, whether it’s the external dimensions of a pipe or tool, the internal width of a hollow object such as a bearing, or even the depth of a recess or hole.

In practice, you’ll find yourself reaching for a micrometer whenever accuracy is critical. This is especially the case when working with machinery that relies on moving parts. Components like pistons, for instance, must operate in perfect alignment—any minor deviation can compromise their performance over time.

The same holds true for bearings, where exact measurements are crucial to ensure smooth rotation and longevity. Precise measurement is equally important in applications such as pipe fittings, particularly when the pipes are intended to carry light gases like helium.

In such cases, even a tiny gap can make a significant difference. Additionally, micrometers are often the tool of choice when checking the thickness of sheet metals, where accuracy is non-negotiable.

How Do I Read a Micrometer?

Before taking any measurements, it’s essential to confirm whether your micrometer uses the English or metric system. Using a micrometer that matches the unit system of your project ensures consistency and prevents errors.

When you’re ready to take a measurement, rotate the micrometer until it fits the object being measured. The final reading is determined by combining the values indicated on both the spindle and the thimble. Together, these numbers provide an accurate measurement.

The process of reading these values can differ based on the specific model and design of your micrometer. For precise instructions, it’s best to refer to the manufacturer’s guidelines included with your tool.

FAQs

What is the micrometer gauge used for?

A micrometer is an instrument used for making precise linear measurements of dimensions such as diameter, thickness, and lengths of solid bodies. It is made of a C-shaped frame with a movable jaw operated by an integral screw.

What is a screw gauge used to measure?

Screw Gauge is a mechanical tool that facilitates measuring the diameter or radius or thickness of a thin wire or thickness of a thin metal sheet with utmost accuracy. Figure1 shows the schematic of the Screw Gauge. This tool consists mainly of a U shaped frame and a spindle (or screw) attached to the thimble.

What does a micrometer do?

Micrometers are specially designed for the measurement of very small objects. They allow for the highly precise measurement of any item that fits between the anvil and spindle. Standard types of micrometers can be used for the fine measurement of items under one inch in length, depth, and thickness.

What is a screw thread micrometer used for?

Screw thread micrometer is a high precision measuring device employed for screw thread control. This type of micrometer allows knowing the average diameter of the thread and the core diameter of the screw.

How to use micrometre screw gauge?

In order to measure an object, the object is placed between the jaws and the thimble is rotated using the ratchet until the object is secured. Note that the ratchet knob must be used to secure the object firmly between the jaws, otherwise the instrument could be damaged or give an inconsistent reading.

What is the advantage of micrometer screw gauge?

Micrometers can provide a higher amount of precision and accuracy than calipers. Additionally, task-specific micrometers are available which can be used, such as inside micrometers that are used for measuring the internal diameters and thickness of cylinders and rods.