Chain drives are a go‑to option when power has to move between components spaced fairly far apart—though they handle short spans without complaint too.

Among mechanical transmission choices—shaft couplings, gear trains, belt drives, lead screws, and chains—chains sit firmly in the “used all the time” group. Each method carries its own trade‑offs, so the selection isn’t a coin toss; engineers weigh pros and cons before committing.

Here, I’m zeroing in on chain drives and the main variants you’ll run into. They’re integral to a lot of machines, and they’re not limited to simple power transfer either—but I’ll get to those side gigs in a bit. First, some groundwork.

What is a Chain Drive?

Think of a chain drive as a straightforward way to move mechanical power from one spot to another. You see it all the time on bicycles and motorcycles—the chain takes power from the engine or pedals and hands it off to the wheels. The same idea shows up in plenty of other machines, too.

In most setups, that power rides along a roller chain—often called the drive or transmission chain—which loops over a sprocket. The sprocket’s teeth slip neatly into the holes of the chain links. Turn the sprocket, the chain is pulled along, and the whole system gets its push.

A chain isn’t one solid piece; it’s a series of rigid links, each joined by a pin so the chain can flex around both the driving and driven wheels. Those wheels have specially shaped teeth that match the recesses in the chain links.

We usually call these toothed wheels sprocket wheels (you’ll also hear “bus sprockets” in some contexts). Because the teeth and links lock together, chain and sprocket move as a pair—no slipping—so the velocity ratio stays exactly what you designed it to be.

Where are chains most useful? When you need to move speed and power between shafts that aren’t very far apart—bikes, motorbikes, farm equipment, conveyors, rolling mills, road rollers, and so on. That said, chains can span longer gaps too—center distances up to about 8 meters are workable. Typical operating limits: speeds up to roughly 25 m/s and power around 110 kW, though higher loads aren’t unheard of.

Conveyor systems often use a different flavor: block chains. These are made of solid or laminated blocks tied together with side plates and pins. The blocks mesh with sprocket teeth just like roller chains do. Depending on what you’re moving, you can bolt on buckets, hooks, or other attachments to those blocks to carry material along.

Terminology of Chain Drive

- Chain pitch (p): This is just the center‑to‑center distance between one link’s hinge pin and the next one. In symbols, we usually call it p.

- Pitch‑circle diameter (PCD) of a chain sprocket: When the chain sits on a sprocket, all those hinge centers line up on an imaginary circle. That circle is the pitch circle, and the diameter across it is the pitch‑circle diameter.

Types of Chain Drive

Following are the three types of chain drive:

- Hoisting and hauling chain drive

- Conveyor chain drive

- A power transmitting chain drive

Hoisting and Hauling Chain

A hoist is a mechanism that lifts or lowers a load by winding a rope or chain around a drum or a lifting wheel (sheave). Power can come from a person on a hand chain, an electric motor, or compressed air. The lifting element itself may be a chain, a fiber rope, or a wire rope, depending on the application.

If you want a familiar example, think of an elevator: its car moves up and down because a hoisting system raises and lowers it. In everyday industrial setups, the load is usually grabbed with a lifting hook.

Chains used for hoisting (and hauling) typically run slowly about 0.25 m/s at most both for safety and control. Two common chain constructions show up in these systems:

- Oval-link chain

- Each link is oval and welded closed.

- The mating sprockets have pockets shaped to receive those oval links.

- Because of the geometry and fabrication, these chains are reserved for low-speed duties—classic chain hoists or anchor chains on ships are good examples.

- Square-link chain

- Here the links are square.

- You’ll see this style in hoists, cranes, and dredging equipment.

- It’s cheaper to manufacture than the oval-link type, but it’s also more prone to kinking when overloaded.

Conveyor chain

A conveyor chain is a specialized type of chain designed specifically for use in chain conveyor systems. At its core, this chain is made up of a sequence of simple bearings, all linked together using connecting plates. Each individual bearing includes a pin and a bushing, providing a surface for the chain roller to rotate smoothly.

These chains play a crucial role in the continuous lifting and transportation of materials, operating at speeds that can reach up to 2 meters per second. Generally, conveyor chains fall into two main categories:

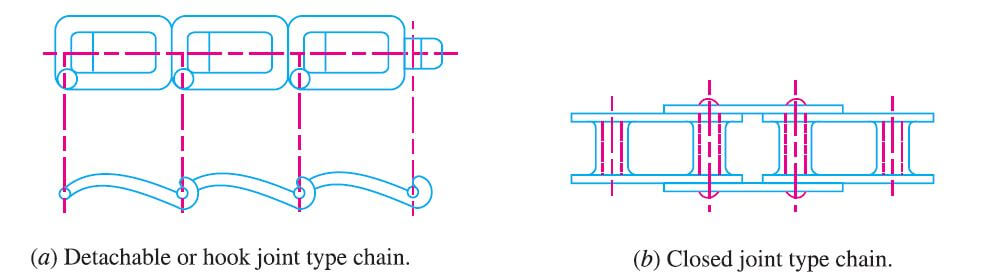

- Detachable or hook joint type: This style is commonly chosen when the distance between the power transmission points in the conveyor is relatively short. Its design allows for easy removal and replacement when necessary.

- Closed joint type: In this variation, the chain is formed from a barrel and a link that are cast together as a single piece. To enhance its durability and strength, the entire chain undergoes a heat treatment process.

Both types are tailored to meet different operational needs, depending on the layout and requirements of the conveyor system in which they are used.

Conveyor chains are usually made of malleable cast iron. These chains do not have smooth-running properties. The conveyor chain operates at a slow speed of about 0.8 to 3 m/s.

Power Transmitting Chain

power transmission chains are used for the transmission of mechanical power when the distance between the centers of shafts is short. These chains have provisions for efficient lubrication. The power transmitting chains are of the following three types.

- Block or bush chain

- Bush roller chain

- Silent Chain

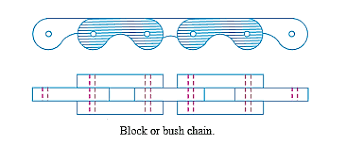

1) Block or bush chain

In the early phases of power transmission development, this kind of chain saw common use. However, one notable drawback is the noise generated when the links come into contact with the sprocket teeth—especially as the chain engages or disengages. Because of this, these chains tend to be used primarily in conveyor systems operating at relatively low speeds.

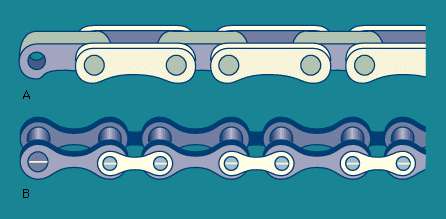

2) Bush Roller Chain

A bush roller chain is made up of several key parts: the outer plate (also called the pin link plate), the inner plate (sometimes referred to as the roller link plate), pins, bushes, and rollers. In its construction, a pin is fitted through a bush, which is held securely within the hole of the roller and sits between the two sides of the chain.

One notable feature is that the rollers can spin freely around the bush. This design isn’t just clever; it actually helps reduce wear and tear on the sprocket wheel’s teeth. To ensure strength and durability, the pins, bushes, and rollers are typically made from alloy steel.

What really sets the bush roller chain apart is its combination of strength and straightforward design it’s robust, and it’s also not difficult to manufacture. This type of chain performs reliably even in tough environments.

You might notice a bit of noise when it’s running, and that’s mainly because the rollers hit against the sprocket wheel’s teeth. Lastly, it’s worth mentioning that this chain doesn’t require a lot of lubrication, so it works well even if only a small amount is present.

Over time, when a roller chain starts to stretch or wear out, the length of the chain increases just enough that its pitch no longer matches the spacing of the sprocket’s teeth. This small mismatch means the rollers no longer sit neatly in their intended spaces on the wheel.

Instead, they can rest unevenly, causing most of the load to fall on just one tooth or perhaps a couple of teeth. Naturally, this uneven pressure speeds up the wear not only on the rollers themselves but also on the sprocket’s teeth.

It’s worth noting that roller chains are manufactured based on standard pitches, ensuring compatibility and interchangeability. They come in various configurations to suit different needs: you’ll find single-row types (simplex), as well as multi-row options like duplex and triple-strand chains.

3) Silent chain

A silent chain sometimes referred to as an inverted tooth chain is specifically engineered to counteract the negative effects of stretching while providing a remarkably quiet operation.

One of the clever aspects of its design is how it adapts as the chain wears and its pitch slightly increases: the links naturally shift to ride on the sprocket teeth at a marginally larger radius. This subtle adjustment helps compensate for minor changes in pitch without requiring intervention.

Another important point is that, thanks to the way the inverted tooth chain engages with the sprocket, there’s no relative sliding between the chain’s teeth and the wheel.

If you keep this chain properly lubricated, it can deliver long-lasting, reliable performance, all while running with minimal noise and exceptional smoothness.

Advantages of Chain Drive

These are some advantages of chain drives compared with belt drive and gears:

- Useful across a wide range of center distances. Chain drives work reliably on both short and long spans.

- One chain can drive multiple shafts. A single loop can be routed to power several shafts at once.

- Compact layout. They deliver high power in a small package, keeping overall dimensions down.

- Resistant to fire risk. Exposure to fire hazards doesn’t typically compromise operation.

- Stable across temperatures and environments. Heat, cold, dust, and general ambient changes have minimal effect on performance.

- No initial tension needed. Unlike many belt systems, a chain drive doesn’t require pre-tensioning.

- High efficiency. Efficiencies commonly approach about 96%, so very little input power is lost.

- No slip or creep. Positive engagement between sprocket and chain gives an exact velocity ratio.

- Straightforward installation. Fitting and aligning a chain drive is generally uncomplicated.

- Low upkeep costs. Routine lubrication and occasional adjustment are usually all that’s required.

- Handles abrasive conditions. Grit and particles that would quickly wear a belt are less of an issue for a properly lubricated chain.

- Operates in wet environments. Water or moisture doesn’t prevent a chain from transmitting power effectively.

Disadvantages of Chain drive

- If the system actually needs slip (some drives do), a chain is the wrong choice.

- Sprockets and shafts have to line up far more precisely than with a belt drive.

- Making chain drives typically costs more (and is fussier) than producing belt drives.

- They’re thirsty for lube—regular lubrication is a must.

- Compared with gear drives, their load-carrying ability is on the lower side.

- Traditional chains shake a bit because of the chordal effect, so vibration is a built-in annoyance.

- Don’t expect them to work with non‑parallel shafts; they’re just not made for that layout.

- When you need razor‑sharp, perfectly smooth motion, a chain isn’t ideal.

- Mounting has to be done carefully and accurately—sloppy installation shows up fast.

- Slack creeps in, so you’ll need a tensioner or some adjustment method to keep things tight.

Application of chain drive

Chain drives are used in many types of industrial applications, such as:

- Chain drives are commonly used when power needs to be transmitted over a distance that’s too great for gears to be effective. They offer a reliable solution where direct gear connections just aren’t practical.

- They play an essential role in rigging and shifting heavy materials, especially in environments where lifting and precise movement are necessary.

- A typical example of chain drive use is in the operation of hydraulic lift truck forks, where controlled vertical motion is key.

- One of the key benefits of chain drives is the ability to adjust the output speed of a driver. This is done by changing the gear ratios between the driving component and the driven sprocket, allowing for either an increase or decrease in speed as needed.

- You’ll also find chain drives in overhead hoist systems, where they help handle loads with both safety and efficiency.

- Another widespread use is in running conveyor belts, ensuring steady and synchronized movement of goods or materials across production lines.

- Overall, chain drives are used across a range of industries from transportation and agricultural machinery to material handling systems and building construction thanks to their strength, versatility, and adaptability.

FAQs

Is chain drive faster than belt drive?

Belt drives are slightly faster than other models. This is an added convenience, but it probably won’t make a big difference in your day to day. Similarly, one disadvantage of chain drives is sometimes the chain needs readjustment, but this will only come up once or twice in their lifetime.

Do cars use chain drive?

The chain drive mechanism is widely utilised in vehicles like cars, motorcycles and bicycles, farming machinery, and more. The chain drive system is often found in older or high-performance vehicles where durability and strength are crucial.

How many types of chain drive are there?

Chain drives can be divided into three main types:

1. Power transmission chain drive.

2. Conveyor chain drive.

3. Hoisting and hauling chain drive.

What are the disadvantages of chain drive?

Disadvantages of Chain Drives

1. Cannot work with non-parallel shafts.

2. Chain drives are known to be noisy and they can also cause vibrations.

3. Misalignment may cause the chain to slip off.

4. Some designs require constant lubrication.

5. An enclosure is usually needed.

Why would you use a chain drive instead of a belt drive?

In favor of chains: Load capacity: Belts are suitable for systems with low to moderate load, but stick to chains for heavy-duty applications, because of their higher load bearing and torque capacity, unless you’re using something like the Gates PolyChain series.