what is AC Power Cords?

A line cord is a portable device for conveying alternating current (AC) from an electricity supply to electrical devices and appliances.

Acord can be used in many industries: retail, industrial, electronics, entertainment, and residential. They provide several types of applications: lighting, power tools, household appliances, shop equipment, musical instruments, etc.

AC Power Cord Construction

AC power cords carry alternating current (AC), which means that the electrons move in one direction and then the opposite direction they continuously and periodically change directions, transporting energy from the power source to the device.

Power cords are made of conductive wires (also called conductors) often made from copper. These conductive wires are insulated and covered (shielding) with an outer layer made of rubber or polymer. Depending on the application purpose, power cords can be constructed differently.

When developing and selecting materials for AC power cords, you should consider:

- Operating voltage which determines the thickness of the insulation.

- Current carrying capacity which determines the cross sectional area of the conductors.

- Environmental exposure (impact, water, chemically unsafe or UV light). This determines the jacket material and construction.

Conductor: Copper Wire

Copper functions as an electrical conductor in many electrical wiring applications, which are vital to power generation and distribution, electrical and electronic circuits, telecommunications, and the manufacturing of electrical contacts.

Building wiring applications constitute the largest market for copper wire, with close to 50% of all mined copper, which is used to produce wire and cable conductors.

Cables of copper wire are frequently stranded by braiding, twisting or bonding, to provide maximum flexibility of the cord.

Copper wires will be bare or tin plated to prevent oxidation, and can be plated with silver or gold for durability and ease of soldering.

Coaxial cables and twisted pair cables minimize electromagnetic interference and maintain signal quality and helps aspect of the transmission properties. Cables are shielded using wire mesh or foil.

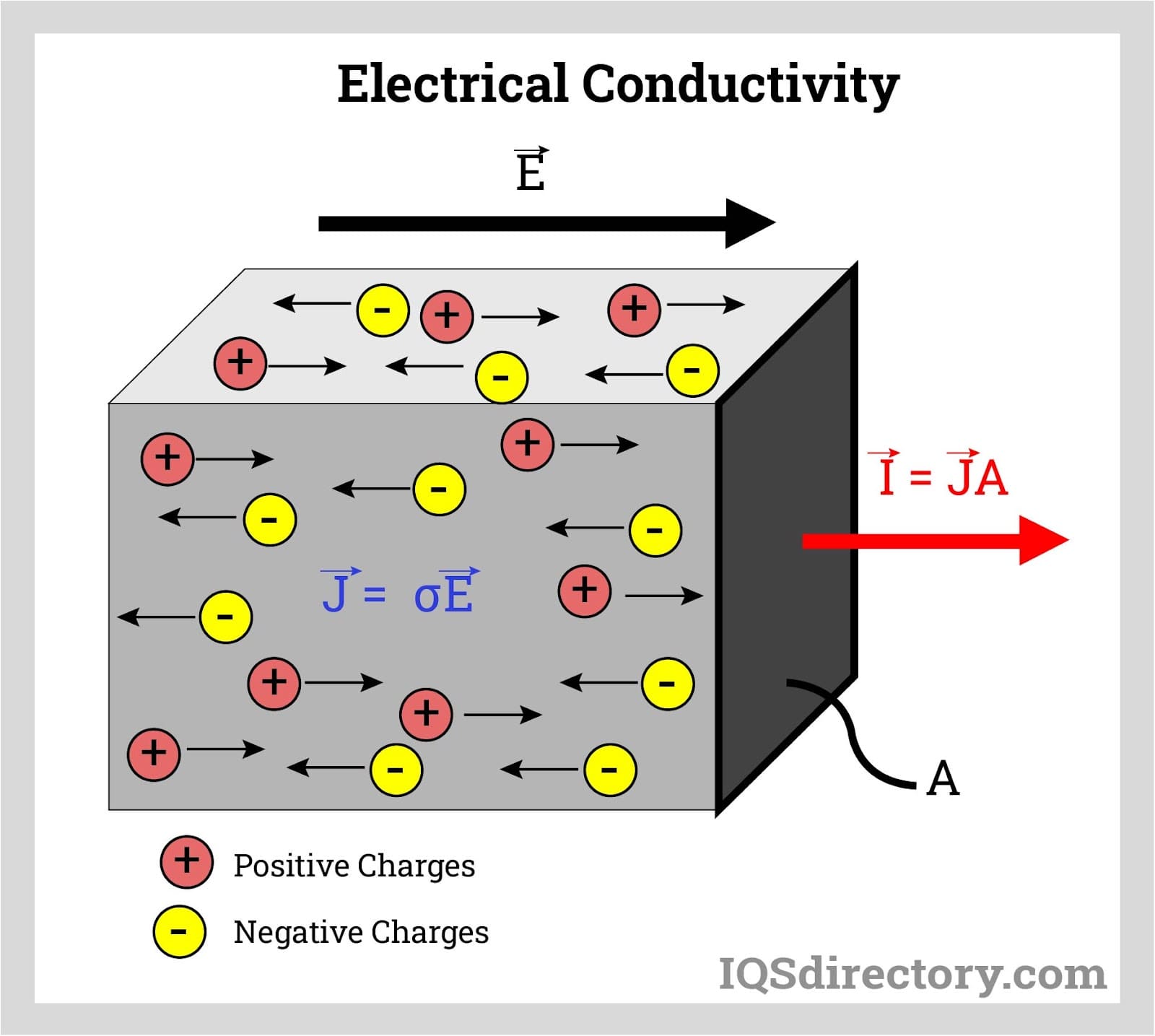

Electrical Conductivity

Electrical conductivity is the key indicator of any material. Electrical conductivity is basically a measure of how easily electric charge can be transmitted. Copper has a very efficient conductivity and is listed to have a resistivity of 16.78 nΩm (nano ohm meter) at 20°C.

Based on solid state metal theory, copper is partially filled in relation to the conduction band, meaning there are a high number of electrons available for the conduction of electric current.

When current is applied to the copper, the electrons will flow to the positive end, which will then initiate the current.

Electrons may experience resistance as a result of impurities or disturbances in the lattice structure of materials such as a Crystal Lattice. This is otherwise known as the “mean free path,” which varies inversely with the resistivity of a material.

Copper is a good conductor of electricity and the standard. Electrolytic-tough pitch (ETP) copper is a preferred choice due to its conductivity efficiency with a lowered oxygen level.

Copper is superior to aluminum for conductive capacity despite its higher density; it can perform to higher current carrying capacities without requiring as much cross-sectional width as aluminum,

Which would require a cross section that is 1.56 times greater to carry the same amount of electricity because aluminum is only a 0.6x conductor of electricity compared to copper.

Silver only marginally performs better than copper functionally in conductivity although silver has a lower resistivity of 15.9 nΩm at 20°C.

Tensile Strength

Tensile strength represents maximum force a material can tolerate until failure occurs. That is why copper’s relatively high tensile strength inhibits a material from stretching, breaking, or deforming under load.

Copper’s tensile strength resists necking and creep but adds weight compared to about the same conductivity in aluminum wires, which may, when it is installed, offset copper’s tensile strength.

Ductility of Copper

Ductility refers to the ability of a material to accept tensile stress and therefore be drawn in to wire form. Copper has a very high ductility and is only surpassed by silver and gold. Copper is easily drawn into very small wire sizes with precisely specified characteristics.

Ease of Installation

Copper’s desirable combinations of hardness, flexibility, and ease of handling support simple installation without special fittings or joining tools. It can be bent and twisted during installation without breaking, and it has secure connections that negate using standards or lugs.

Conductor: Aluminum Wire

Aluminum wire, which is used for the electrical wiring in homes, has a number of applications for use in electric power systems, particularly as part of transmission and distribution lines. Aluminum provides a better conductive per weight than copper, which can be a potential cost savings for certain use cases.

Aluminum is subject to AC magnetic fields and eddy current problems due to its excellent electrical and thermal conductivities – somewhat like 60% compared to copper – although with lower density.

Fire from loose connections limits the application of aluminum. Aluminum also has a larger electrical resistance requiring thicker wire to match copper equivalents.

Electrical Resistance

Due to higher resistance, aluminum needs thicker wires than copper for the same amount of current load, adding space restrictions for installation and circuit design.

Ductility of Aluminum

Aluminum’s less ductility leads to less fatigue at risk, and the internal problems of internal wires are faster, and causes heat because of the discussed resistance.

Galvanic Corrosion

Exposure to moisture can cause aluminum to galvanically corrode when it is in contact with certain metals, which creates safety risks.

Oxidation of Aluminum

Aluminum oxidizes more readily than copper, creating an oxide that is less conductive than copper oxide, potentially compromising the integrity of the connection and increasing fire risk.

Aluminum Malleability

Greater malleability can result in deformation and compression of aluminum, which results in displacements and greater loosening and resistances, creating a potential safety issue.

Thermal Contraction and Expansion

Aluminum thermal changes exceed those of copper, therefore aluminum is at an increased risk of degrading connections over time, especially in a continuously installed situation affecting performance.

Excessive Vibration

Vibrations may lead to loosening over time and can present problems for the use of aluminum in high vibration environments.

Wire Insulation

Insulation is intended to separate the electrical path from things like leakage, environmental spoilage or harm to the conductor from external forces. A good quality insulation is important with regard to expected life and performance.

Different insulation types target specialized applications; rubber, plastic and fluoropolymer are the main materials. Insulation covers are either for individual conductors or multi-wire cords; selecting an insulation cover depends on the application and the challenges presented by the environment.

Plastic Insulation

Plastic options such as:

1. Polyvinyl Chloride (PVC).

PVC provides a flexible and cost effective insulating option that meets a range of temperatures from -55°C to 05°C. It is flame and abrasion resistant wet resistant, and withstands chemicals and solvents.

PVC is harmless, making it suitable for use in medical and food equipment. Its drawbacks are limited flexibility and poor performance in lower temperatures. PVC’s higher attenuation and capacitance losses are poor values for energy efficiency.

2. Semi-Rigid PVC (SR-PVC).

SR-PVC provides primary insulation with high abrasion resistance to aid in protection from chemicals, heat, and flame.

3. Plenum Polyvinyl Chloride (Plenum PVC).

Plenum PVC meets strict fire safety specifications and is well-suited for air-circulating voids such as ceilings or floors.

4. Polyethylene (PE) Insulation.

Preferred for low-capacitance wires and coaxial cables, polyethylene (PE) offers high-speed transmission capability because of its comparatively low dielectric constant. Cross-linking can improve durability to grading and even solvent.

Whereas polyethylene can be provided in a wide range of temperatures, polypropylene provides a bit more structural rigidity. Although flammable, the addition of flame retardants can increase dielectric loss, which could affect energy transmission.

5. Polypropylene insulation (PP).

Polypropylene is similar to PE, but offers a wider temperature range. PP is even used for thin-wall applications because PP allows for better electrical insulation (by foaming).

6. Polyurethane (PUR) Material.

Commonly used when flexibility and chemical resistivity are important, such as military cords. It’s flammable as an insulator, but functional as a jacket.

7. Chlorinated Polyethylene (CPE).

An environmentally beneficial material that has excellent resistance properties for industrial control and power cables.

8. Nylon Insulation.

Nylon has high strength, sustained resistance to chemicals, and is durable against cuts and abrasion, however it has a significant vulnerability to moisture absorption which can impact some electrical properties.

Rubber Insulation

Rubber offers an array of options:

1. Thermoplastic Rubber (TPR)

TPR, which is an evolution from thermoset, improves the processing rates for manufacturers and offers more color solutions and a smoother lay-out. However, it has less cut-through than other alternatives.

2. Neoprene (Polychloroprene)

Neoprene is well suited for portable cord applications and military products because of its excellent cut-through, flame resistance, and oil resistance characteristics.

3. Silicone insulation

Silicone has high operational temperature resistance with average abrasion resistance and flexibility; Useful across electrical spaces.

4. Ethylene Propylene Rubber (EPR)

Preferred for high-voltage applications because of its small cross-sectional capacity, has great flexibility but needs to be designed properly when installing because of its relatively soft nature.

5. Rubber Insulation

Combining natural rubbers with SBR will provide hybrid properties which are normally threshold limits for general purpose applications as consistent with either thermal requirements or electrical resistance.

Fluoropolymer Insulation

With options such as:

1. PFA (Perfluoroalkoxy polymer) insulation

Usually heat resistant with limited applications are more expensive insulation options.

2. Thermoplastic elastomers (TPE)

Combining the flexibility of rubber with the handling of plastics, TPE is used in housing and automotive applications, although they will have limitations with heat and or chemical resistance.

3. Polytetrafluoroethylene (PTFE) Insulator

Flexible as they can be, PTFE are chemical and heat resistant, and are mostly useful when mechanical flexibility is priority.

Jacket Material

Polyvinyl chloride (PVC) functions well in indoor applications.

Rubber would add mechanical strength and polychloroprene has improved thermal characteristics over non-polychloroprene rubber.

Textile jacketing has excellent abrasion resistance and long service life.

End Types for Power Cords

NEMA defines voltage and connector standards based on pin configurations and grounding, impacting the utility and use of the power cord.

Hard wired cords have terminated or wired ends for permanent connections.

International standards are governed by organizations such as CE (European Commission), such as EN 60320 for European electrical connectors.

Operation of an AC Power Cord

AC power cords carry alternating current to appliances and maintain the flow of a safe current to the appliance. The live wire sends a voltage to appliance and changes direction periodically.

The neutral wire takes this current and returns it to the ground or busbar in the distribution box, so that electricity can continue to flow in a circuit.

Earth wires make sure people are not shocked, as they connect to the ground and stop faults, and trips safety breaks and cuts current supply in emergencies.

Considerations for Selecting AC Power Cords

When it comes to choosing AC power cords, consider these aspects:

Rated Current

The rated current of a cord describes the maximum current the cord can handle without overheating. rated current can vary with numerous factors including; insulation, frequency of current, resistance, and surrounding conditions.

Rated Voltage

The rated voltage may dictate some of the fundamental design parameters of equipment such as insulation type, insulation thickness, and aligns safety requirements with the requirements of reliability of performance under high voltage conditions.

What are the different types of AC power cords?

AC power cables or mains power cables are defined as power cords safely conveying electric power and current to electrical and electronic devices and appliances from wall outlets.

Identification of AC power cables varies depending on the connectors (plugs), which are sometimes referred to as couplers, making a secure and also dependable connection between the power outlets and available power supply.

In addition to the connectors are all the various type of plugs (connectors) in the cable, important also in describing the type of cable used. There are a variety of connectors and plugs that meet internationally and regionally recognized standards, as well as for specific voltage, current and device type.

Knowing the differences between types of AC power cable (such as electric cord or power cord), is important for selecting the right cable for your application. Key considerations for selecting AC power cable are for effectiveness, safety, and to recognise applicable electrical regulations.

C13/C14 AC Power Cord

The International Electrotechnical Commission (IEC) developed the IEC 320 C13/C14 connector standard for alternating current (AC) power cords. This standard is known to regulators as IEC 60320.

Commonly found in the IT, data centre, and office equipment industries, connector types C13 and C14 are often used in power cords that supply electricity to computers, printers, monitors, power distribution units (PDUs), and networking equipment.

As a female connector, the C13 line socket is the most common connector found in desktop computers’ power cords. The male connector is the C14 plug, usually mounted on recessed panels or chassis on power supplies and uninterruptible power supplies (UPS).

The C13/C14 combination supports current ratings up to 10A (US) or 15A (many countries) and voltage ratings up to 250V, making it capable of a large variety of low- to medium-power electronics devices.

The globally recognized design creates an environment that is tested for interoperability and safety of power delivery across electronics and appliances.

C5 “Mickey Mouse” AC Power Cord

The C5 polarized power connector—commonly characterized as a “Mickey Mouse” or cloverleaf connector—is broadly used in AC power cords for notebook computers, projectors, and portable power adapters.

There are three circular prongs in the C5 power connector are arranged in a triangular pattern that looks exactly like the silhouette of the Disney Character, hence the name.

The C5 power cord is quite popular with OEM laptop manufactures, because of its small size and also because it fits much more tightly than a standard computer 3 prong power cord. Typical applications include powering laptops, some game consoles, portable speakers and old school printers.

C5 AC power cords conform to international electrical safety regulations, providing a safe and effective means of electrically connecting the latest consumer electronics.

In contrast, users in search of a reliable power solution for portable or mobile applications, would want to have the C5 connectors to achieve versatility, robust electrical contact, and broad compatibility.

C7 AC Power Cord

The C7 power connector is a 2-pronged non-polarized plug used for AC power cords found with many electronic products (radios, shavers, small appliances, power transformers, and etc.). The C7 is also referred to as the “figure-8” or “shotgun” connector.

The C7 has two round pins, position right next to each other. Generally, the C7 AC power cord is used to power lower voltage equipment such as portable laptop power supplies, CD/DVD players, game consoles, audio and AV equipment.

This is a small and lightweight power cord connection that is commonly found on consumer electronics that use a moderate level of electric current but has a simple, no-ground connection.

C7 Polarized AC Power Cord

The C7 connection has a polarized variant designed for safety and to prevent mismatching connections. The primary distinction of the polarized C7 AC power cord is the inclusion of a square-shaped overmold on one of the pins to ensure the prongs are inserted in the proper orientation.

This design allows for proper orientation of terminal connections and ensures that the neutral terminal of your device is directly, safely wired to the neutral wire of an AC supply.

Reducing risk of faults or reverse polarity in sensitive equipment. These cords are common. They are utilized for devices that require polarity to function as intended, in a safe manner.

C15/C16 AC Power Cord

The C15 and C16 connectors are enhanced IEC connectors that are used in high-heat, heavy-duty applications. These connectors are often applied within data centers, server rooms, and industrial environments where there are many devices close together.

The application of so many devices generates a lot of heat. The C15 connector is often used for electric kettles, networking gear, hot-pluggable rack equipment, and power distribution concentric systems.

The only way that C15/C16 connectors differ from C13/C14 connectors is that they have an additional notch/key that precludes mis-insertion and matches “cold” and “hot” orientation.

The C15 and C16 connectors have higher temperature ratings (up to 120°C) compared to the standard C13/C14 connectors to be utilized in mission-critical environments.

There is also a C15A/C16A for extreme environments (up to 155°C) that have a rectangular notch in the upper-end molding. These power cords play an important role in enterprise-level power management and industrial electrical deployments where safety and assurance is critical.

C19/C20 AC Power Cord

The C19 and C20 power connectors are heavy-duty AC power cord (cable assembly) series using a horizontal terminal orientation and heavy-duty, rectangular connector with rounded corners.

The C19/C20 connector has seen widespread deployment in data centers, server farms, network

infrastructure, and in professional IT Equipment. The C19/C20 connector can provide higher amperages (up to 16A internationally and 20A in US specs) at voltages up to 250V.

The C19/C20 connector is used for high-powered devices in the IT field that exceed the ratings of the C13/C14 cords. Examples of these high powered devices are servers, large supplies, blade enclosures, industrial-grade PDU’s, and mission-critical medical devices.

The C19/C20 connector is used for high powered devices in the IT realm that exceed the ratings of C13 C14 cords. These high powered devices include servers, large power supplies, blade enclosures, industrial-grade PDU’s, and mission-critical medical devices.

C13/Type G AC Power Cord

The Type G plug—used within the United Kingdom, Ireland, and a number of Commonwealth countries—has three rectangular prongs and a fuse embedded internally, which is commonly rated at 13A.

The internal fuse protects the power cord and the connected electrical appliance from overload, adding another layer of safety.

Some Type G sockets are compatible with a few other plug types (Type C in rare cases), however, using such adapters or plugs that are not to code is unsafe, and in many cases the use of such plugs voids warranties and/or damages the devices.

British Standard BS 1363 is the main standard defining type G plugs and sockets, and is used extensively in residential and commercial wiring in the UK and elsewhere, along with its derivatives, which have similar restrictions on plug/socket safety, strength and compatibility with fused AC power cords.

If you are traveling internationally, or if you have consumers who are buying your devices in different countries, it’s important to check the compatibility for socket standards like type G, when deciding on a power cord to supply AC.

Choosing the Right AC Power Cord for Your Application

With so many types of AC power cords and connectors, it can be tricky to figure out what would fit your device and area.

The first step is ensuring that voltage and amperage that your equipment requires is matched with the electrical ratings of the cord (e.g. 125 Volts, 250 Volts, 10 Amperes, 16 Amperes, and 20 Amperes) and ensuring that you’re using a compliant plug type to match the wall socket in your country.

When you buy AC power cords online or through local distributors, be sure to look for third-party certification markings (e.g. UL, CSA, VDE, RoHS complied) for safety and dependability in the long term.

Many manufacturers and distributors also offer custom power cords to meet any specific requirements, including wire length, shielding or specific connectors for medical and industrial applications.

If you need to bulk order, OEM or international sourcing, check with reputable AC power cord manufacturers and/or authorized distributors.

The knowledgeable suppliers will be able to offer you insight to the best possible products for your data centers, IT infrastructure, home electronics, or specialized environments, so you’re sure to choose the correct products for the application to ensure safety and energy efficiency.

To learn more or to compare products, take a look in our Leading Manufacturers and Suppliers section below for reputable sources and high quality AC power cords.

What are the applications and benefits of an AC power cord?

This chapter will explore the applications and advantages of AC power cords.

Applications of AC Power Cords

AC power cords are used in a variety of applications, including:

Building Applications

- Church equipment

- Public outdoor lighting

- Libraries

- Public service buildings

- Data centers

- Airports

- Home appliances

Industrial Applications

- Refineries and oil platforms

- Chemical facilities

- Heat treatment of materials

- Pharmaceutical plants

- Foundries

- Nuclear power stations

Benefits of AC Power Cords

- AC power cords provide a way to connect AC appliances to the mains supply.

- Comparing loss of energy in AC Power cords is less than loss in other cables.

- If the specifications (for input voltage and range) change, it is possible to change to an alternative or substitute AC power cable.

- Easy to replace in the case of power supply failure.

- By being able to use the power supply, the manufacturers are able to reduce the total number of components in the appliances, the part and assembly costs.

- AC power cords are flexibile and can fit into any location in the installation, such as under floors, horizontally or vertically against walls, or behind products.

- They provide a safer method of dealing with AC current as their insulation is excellent.

- They have less internal resistance in the cable because they are using alternating current.

Drawbacks of AC Power Cords

- When current travels through an AC power cord, the magnetic fields created may induce interference with some appliances, as well as communications systems.

- The use of poor conductors in power cables results in a heat accumulation which is sufficient to char the insulation.

- Cable sheath materials can degrade over time.

- AC power plugs are subject to degradation when sufficient currents are passed through it.

AC Power Cord Standards and Specifications

In working with materials that transfer electrical current, safety considerations must be observed. Polarization and grounding become especially critical when higher-voltage electrical equipment or electrical appliances are involved which are potentially more dangerous in case of electric shock.

Polarization of an electric plug ensures that the appliance is connected properly to the ground or neutral side of the circuit and protects the user in case of electric shock.

In all cases, any sensitive electrical products and equipment should be used with a properly grounded or polarized AC power cord.

AC Power Cord Maintenance

AC power cords typically require no maintenance because they are passive devices that do not have any moving parts; therefore, only a few measures can be taken to help the AC power cord have optimum service life.

Use the power cord within the amperage specified by the manufacturer and do not overload the cord; overheating could compromise wire insulation. In an area such as a server room with multiple power cords, the cords should be arranged and bundled together to prevent tangles.

AC power cords should be used in dry areas: moisture can enter the power connectors. Occasional dusting will keep the AC power cables clean and in good working condition.

Conclusion

An AC power cord is a detachable device for delivering an alternating current (AC) electrical energy to an electrical appliance or between devices powered from a mains power supply.

Providing peace-of-mind for industries such as retail, commercial, industrial, electronics, entertainment, and domestic, as well as for applications in lighting, electrical power tools, electrical household appliances, electrical equipment in shops, musical instruments, and countless personal applications, an AC power cord provides a low resistance passage for an alternating current to pass through.

The live wire (or hot) delivers the 230V/120V AC from the mains power supply to the appliance, with the current alternating at 50 times per second.

A cord is defined as a cable, which is made of a conducting wire (usually copper), insulated with cord covers and further insulation, and finished with an outer rubber or polymer cable jacket that protects the wire from damage.

AC power cords can be differentiated from one another by their connectors or more formally as power couplers. AC power connectors assist in the connection of electronic devices and appliances to available power outlet receptacles.

AC power connectors differ from plugs; however, AC power plugs are commonly referred to as AC power cords. The choice of AC power cords is dictated by rated current and voltage.