Peeled rivets make use of the larger diameter of the locking head for larger bolt hole bearing (underside of head). When the mandrel is drawn through, the body expands and leaves the head in the shape of a flower with four petals. This type of rivet is ideal for fastening metal to softer materials.

The sides (petals) of the rivet fold over creating a head to fasten the two materials. Peeled rivets are suitable for use in the automotive sector, construction projects (plasterboards, coatings, insulation), and can be used for trailers, plastic components, electrical appliances and upholstery (padded covering on furniture).

What is a POP Rivet?

Pop rivets (blind rivets) are a category of rivets. They are specifically used in applications when access to the blind side of the components to be assembled is restricted or unavailable.

Pop rivets are a special type of blind rivet that can be installed from one side. This feature allows for very useful applications in fabrication and assembly when working on components without back side access.

Pop rivets are a relatively simple mechanism with a shank inserted into a pre-drilled hole and a mandrel that fits into the shank. The mandrel is then drawn out using a blind riveting tool and pulls the material together by compressing the shank on the blind side of the component.

After the joint is made, the mandrel is snapped off at a preset nick so that there is a clean finish. They are called pop rivets because of the noise produced when the mandrel breaks off.

Usually, for the installation, a single gentle pull is all that is needed, but what is needed depends on the rivet size and application. In the case of relatively simple repairs or few rivets to install, a manual pop riveting tool can be used.

In the case of heavier applications, such as manufacturing or construction, a pneumatic or electric pop riveting tool should be used that provides more system pull strength.

How Do POP Rivet Work?

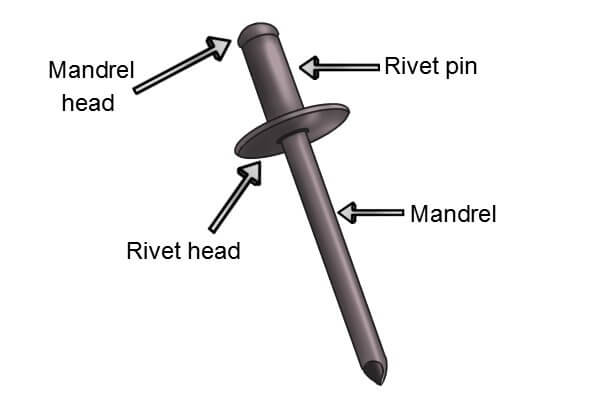

Pop rivets have essentially two parts; The rivet body (which may also be referred to as the shell or hat) and the mandrel (which may also be called the stem).

If it is not possible to access both sides of a component, the first step is to drill a hole through both parts being joined. A rivet is inserted through the hole and the rivet body is pressed against the parts to be joined.

Now that the rivet is positioned, a rivet gun will pull on the mandrel, pulling the mandrel into the rivet body, thus causing the rivet body to begin to expand, thereby creating a permanent hold on the components to be joined.

Once the components are held by the rivet body, the mandrel will snap at the tension point and will be a permanent part of the rivet. This creates a localized joint.

What are the parts of a blind rivet?

- Rivet Pin: The pin is the complete body of the rivet that will fit through the materials being held together.

- Rivethead: The head will sit on the outside of the material to hold the rivet in place from falling out.

- Rivet Mandrel: The mandrel will be placed in the rivet gun when it is installed. When the rivet gun is struck, it will pull the mandrel partially through the pin (body) of the rivet, deform the pin to make a second head, and when the rivet is secured, break off the mandrel.

- Rivet Mandrel Head: The mandrel head will deform the body of the rivet to expand the rivet body, then seat itself into the rivet body to create the second head secured the joins pieces together.

What are the different types of blind rivets?

A blind rivet, or pop rivet as they are known to many, consists of a hollow cylindrical pin (body) and a head. The mandrel, also called the mandrel pin, is a thin long pin with a head attached and goes through the cavity of the body – with the head engaging the opposite end of the body for the rivet head.

Blind rivets come with different types of bodies and heads, and they are also made with different materials.

1. Standard Blind Rivets

Sourcing a blind rivet is generally a simple and inexpensive process. Rivets are used to attach structures together in many applications.

Blind rivets are typically utilized to fasten metal to metal. A standard blind rivet consists of a reasonably compact dome headed steel with a reasonably compact shining steel body.

When you pull the mandrel partially into the rivet body you will deform the end of the rivet body at the “bleed” end and create a second head that will successfully and permanently affix your materials together.

Standard rivets can be found in many applications, including in the automotive world; construction; metal fabrication; electrical appliances; containers; furniture; air conditioning; heating etc..

2. Sealed Blind Rivets

This blind rivet is a blind rivet with a sealed end. In contrast to other styles of blind rivets that had a sealed body, the head of the mandrel will not protrude from the end of the rivet. There are sealed rivets that will not let fluids permeate or leak from the rivet body, thus meant for metal-to-metal joining.

The gap between the head of the mandrel and the end of the rivet constitutes the “seal”. Since the head of the mandrel is encased within the body of the rivet, and the nose of the rivet is sealed, there will essentially be a sealed component, no matter if the fluid is contained and/or air is removed from the enclosure.

They are adequate and serve a function in any number of uses and industries, like automotive, construction, and metal. Sealed rivets can also be utilized in electrical appliances, containers, furniture, and air condition and heating systems.

3. Peeled Blind Rivets

Peeled rivets also form a locking head with a larger diameter so that they have a larger bearing surface (on the underside of the head).

When the mandrel is pulled through and the body expands, the head is in the shape of a flower with four petals. Peeled rivets are used to fasten metal to softer materials.

The rivet sides, or petals, fold over to form a head to fasten the metal to the softer materials beneath it. Peeled rivets are ideal for use in the automotive arena, construction work (plasterboard, coatings, insulation), and on trailers, plastic components, electrical appliances, and upholstery (which is the padded covering on furniture).

4. Grooved Blind Rivets

Grooved rivets feature raised rings around the threaded part of the rivet, which provides excellent grip strength when fastening soft materials (i.e. plastic and wood).

When choosing fasteners for situations where metal to wood fastening or metal fastening to other materials such as cement, bricks, and wood, think about grooved rivets.

The ribs in the body of the rivet become embedded in the material and compress the materials together in a way similar to a screw action. The hole does not need to go all the way through the material.

When the mandrel is pulled back, the tail of the grooved rivet expands within the material instead of creating a head on the other side of the material.

Friction causes the rivet to hold the material securely to each other, not a second head where the previous head is retaining the item being fastened to the material.

These rivets have a great application in construction, metal working, furniture building, injection molded parts, and electrical equipment.

5. Multi-Grip Blind Rivets

Multi-grip rivets are practically the same as standard rivets but with indents on the rivet body. The indents are expanded and provide a multiple grip when the mandrel is pulled through the rivet body. Multi-grip rivets are designed for riveting materials made of metal-to-plastic and plastic-to-plastic.

Whenever the mandrel is pulled through the body of the rivet, and each of the multiple grips are forced against the work materials being riveted.

Multi-grip rivets can be used in automotive, construction, and metalling industries, as well as electrical appliances, furniture, electronics, ladder manufacturers, and air conditioning and heating.

6. Soft Set Blind Rivets

Soft rivets are the same as regular rivets. However, the body and mandrel are made from a softer metal, which tends to be an aluminum alloy. The mandrel breaks with much less force than any other rivet allowing it to apply just the right amount of pressure to fasten brittle materials without damaging them.

Soft rivets are used to fasten metal to plastic, metal to wood, metal to fiberglass, plastic to plastic, and metal or plastic to soft materials that offer little resistance. Soft rivets can be used in furniture, packaging, plastic components, containers, plastic and construction.

7. Blind Rivets Heads

As well as being available in a number of body designs, blind rivets can also have different types of heads.

8. Dome Head Blind Rivets

The dome head provides adequate bearing surface for a multitude of fastening applications with the exception of either smooth and brittle materials such as plastics.

This is due to the fact that the type of head applies more of the pressure closer to the hole drilled which would crush or harm softer materials.

Bearing surface is the surface that it contacts. In this instance, it is the surface area under the head of the rivet that contacts the material that is being fastened.

9. Large Head Blind Rivets

The large head provides twice the bearing surface as a dome head rivet. This offers superior resistance in holding, and is ideal for fastening brittle or soft materials to rigid base materials.

10. Countersunk Head Blind Rivets

A countersunk head fits into the material without the head protruding, keeping a flat surface.

Applications of Blind Rivets

They are utilized for joining materials together, that can include metals, plastics, wood and leather, in high strength joints. In most cases, the application is for joining plastic or thin sheet metal.

To allow pop rivets to fit the various applications, they are made in many types of materials which include, Steel, Stainless Steel, Monel, Copper, Aluminium.

Uses for Blind Rivets:

- Building or Home Applications.

- Attaching Nameplates and Signs.

- Fastening Wall or Ceiling Decorations.

- Attaching Hinges.

- Attaching Door Knobs, Drawer Pulls, and Handles.

- Woodworking Applications.

- Industrial Applications.

Advantages of Pop Rivet

- Being cost effective

- Allowing for joining of parts when there is limited rear access

- Being durable

- Being lighter than bolts/screws (dependent on rivet material)

Disadvantages of Pop Rivet

- Being difficult to remove once placed

- Protruding from the sheet metal surface, potentially creating a hazard and reducing aerodynamics

- Potential corrosion issues if the rivet material differs from the metal parts to be joined

FAQs

What is a pop rivet used for?

Pop rivets can be used to connect wood, metals, or even plastics, and they can be made of specific materials for specialty applications such as when additional strength or corrosion resistance is needed. Lightweight manual pop rivet tools are ideal for simple tasks such as joining metal sheets or thin materials.

Is a pop rivet stronger than a screw?

Compared to screws, rivets hold much better. They are impossible to open and won’t shake loose. This is because the screw only has a head on one side whereas the rivet is supporting both sides. This is also important in the transport process where the frame is subject to vibration.

How strong are pop rivets?

McMaster rates pop rivets in tensile strength as well as shear strength. A 3/16″ aluminum blind pop rivet has a shear strength of 310lbs and a tensile strength of 500lbs.

Are steel pop rivets stronger than aluminum?

steel rivets are stronger than aluminium rivets, but aluminium rivets (and stainless-steel solid rivets) are more corrosion resistant. Your rivets should have the same mechanical properties as the components you’re joining.

Why are rivets no longer used?

Rivets in the metal structures now seems archaic and from other times. However, rivets were extensively used for metal structure in the 19th century and in the first half of the 20th. The use of high-strength bolts displaced the rivets in the second half of the century and nowadays rivets are no longer in use.

Is a pop rivet permanent?

A pop rivet gun is placed on the rivet, pulling the mandrel into the rivet body, causing it to expand and grip the parts to be joined. Once gripped, the mandrel snaps, permanently holding the rivet in place.