A lead screw is a mechanical means of power transmission commonly used by machines for precision actuation that converts rotational motion into linear motion. Other terms for a lead screw (or leadscrew) are power screw and translation screw.

Lead screws are sometimes confused for threaded rods, while they may appear the same to an uneducated observer, the threads on a threaded rod are significantly finer and consequently have a higher susceptibility to deformation due to load.

In this article, we will explore the various types of lead screws, their design, different use cases, advantages, and disadvantages. Let’s get started!

What is a Lead screw?

A leadscrew (also power screw or translation screw) is a screw used as a linkage in a machine and will translate rotating motion into linear motion.

Because screw threads have a greater area of sliding contact between their male and female pairs, they will have larger losses of energy in the form of friction than other linkages.

Leadscrews are not usually meant to just carry a high power, but are typically meant for intermittent use in low power actuator and positioner mechanisms.

Leadscrews are used in linear actuators, machine slides, like in machine tools, vises, presses, and jacks. Leadscrews also are a common part of electric linear actuators.

Leadscrews are made just like other forms of thread, and can be rolled, cut, or ground.

A lead screw is sometimes used with a split nut (also called a half nut) which allows the nut to disengage from the threads and to go independent of the screw’s rotation, allowing it to be moved axially when required (e.g.management will be used while performing single point threading on a manual lathe).

A split nut can be used for wear compensation by compression of the mounted elements of the nut.

A hydrostatic leadscrew incorporates many of the short comings of a regular leadscrew, have greater positional accuracy, very low friction, and very low wear, but have fairly high-pressure fluid and requirement for high precisional manufacturing process this is going to cost more than most of other linear motion linkages.

How Does A Lead Screw Work?

A lead screw operates in two important modes:

- The shaft is stationary and the nut is driven

- The screw shaft is rotating and the nut is being driven

In the first scenario, the nut rotates due to either a hand force, or a motor, and, in this case, the nut moves along the axis of the shaft. Ultimately, the torque on the nut is turned into linear travel.

In second scenario, the nut’s rotation is prevented and the screw shaft rotates instead, causing the nut to move axially along the screw. Therefore, the torque on the screw shaft is turned into linear motion of the nut as well.

Lead Screw Parts

Every screw requires a nut, and lead screws are no different. The lead screw nut is a component that has an internal thread that meshes with the external thread of the lead screw. The lead screw nut also provides a means of attachment to the machine, and facilitates the transfer of the force generated by the rotation of the lead screw.

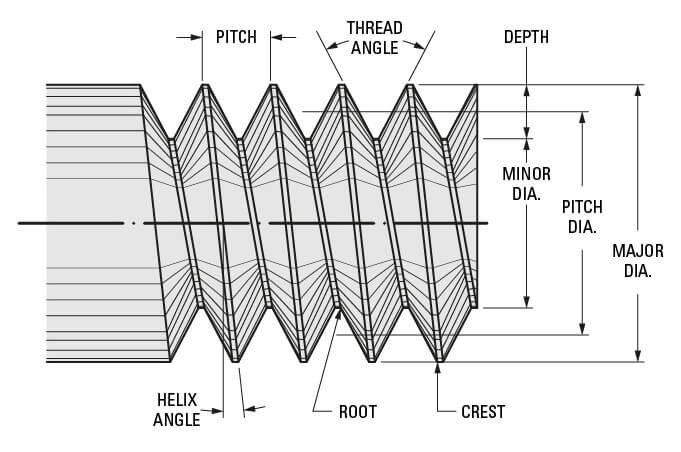

The components of a lead screw are the following:

- Lead screw: The lead screw is cylindrical and has one or a series of helical grooves extending along its length, which are called external threads.

- Thread: The thread allows for the conversion of rotational movement of the screw shaft into linear movement, as the screw shaft and the nut slide with one another.

- Nut: The lead screw nut is a cylindrical section, and has internal threads exactly matching the external threads of the screw shaft.

- Major Diameter: The major diameter is the greatest diameter of the thread. The major diameter of the screw shaft is the distance between two opposite crests, and the major diameter of the nut is the distance between two opposite valleys.

- Minor Diameter: the minor diameter is the smallest diameter of the thread. The minor diameter of the screw shaft is the distance between two opposite valleys, and the minor diameter of the nut is the distance between two opposite crests.

- Crest: A crest in an external thread is a raised helical structure (screw shaft) and a crest in an internal thread is a recessed helical structure (nut).

- Root: A root in an external thread is a recessed helical structure (screw shaft) and a root in an internal thread is a raised helical structure.

- Thread Depth: The thread depth is the distance from root to crest, in the radial direction.Flank: The flank is the surface connecting the root and the crest.

- Pitch Diameter: The pitch diameter, or the effective diameter is half way between the major and minor diameter. This is the diameter of the imaginary cylinder whose circumference is intersected by half of the thread pitch.

- Pitch: The pitch is the axial distance of two adjacent threads measured parallel to the axis. This is equal to 1/thread per inch.

- Lead: The lead is the linear distance moved by the screw shaft/nut along the axis in one revolution (3600 rotation). If you increase the lead, you also increase the linear speed of the lead screw but decrease the load carrying capacity of the lead screw.

- Thread Starts: The number of starts is the amount of independent threads that are run along the length of the thread. The lead of a screw is equal to the number of independent threads times the pitch.

- Helix Angle: The helix angle is defined as the angle between the helix of the thread and the line perpendicular to the axis of rotation. Generally, a lead screw with a higher helix angle has lower frictional losses and a therefore better efficiency. The reasoning being, the number of revolutions to rotate such a screw is lower than a screw with a lower helix angle for the same linear distance covered. But it does take more torque to turn.

- Lead Angle: The lead angle is the complementary angle of the helix angle. It is the angle formed between the helix of the thread and a line parallel to the axis of rotation .

- Thread Angle: The thread angle is the angle formed between adjacent threads.

- Screw Handedness: The screw handedness is used to define the direction in which the thread runs along the length of the screw. A lead screw can be right, or left handed. In the case of right or left hand screws, the thread runs around the screw length in a clockwise or counter clockwise direction respectively.

Pitch vs Lead

Pitch is defined as the distance between the grooves of the screw. It is typically used in relationship to inch products and defined as threads per inch.

Lead is the linear travel the nut makes in one revolution of the screw, which is how ball screws are usually classified. Whenever a screw is single-start, pitch and lead will be the same.

For multiple start screws, lead is equal to the pitch multiplied by the number of starts.

lead screw examples

Here is a list of real-world examples of a lead screw:

- Lathes

- Vices

- Jacks

- CNC machines

- Engraving machines

- Fluid handling machines

- Linear actuators

- Linear stages

- Screw jacks

- Mechanical presses

- Appliances such as printers, disc drives, lifting equipment, and robots.

- Scanners

- Recorders

- Wire bonders

- Machine slides (such as in machine tools)

- Visas

- Heavy lifting applications when combined with a metallic (typically bronze) nut.

- Laboratory and life sciences equipment such as DNA sampling, scanning, and fluid handling devices

- Rapid prototyping

What is a lead screw used for?

Lead screw assemblies are typically used in a linear motion control system as an input to a machine. Lead screw assemblies are also suited for instrument grade applications including the list below.

- Laboratory and life sciences equipment including DNA sampling

- Fluid handling devices

- Engraving

- Rapid prototyping

- Data storage

- Inspection

- Heavy lifting applications (a metallic nut must be selected for this type of application)

- etc.

When considering a lead screw, you must take rigidity into account along with speed, thrust, accuracy, and repeatability for your application.

Material Selection for Lead Screw

Lead screws are subjected to torque, axial compressive load, and sometimes bending moment. Lead screws are usually made from alloy steel.

Because lead screw failure could lead to catastrophic accidents, a factor of safety of 3-5 is used as a rule of thumb. Threads are subjected to shear failure, which can be avoided by using nuts with adequate height. Another possible failure mode for threads is wear as nuts and bolts rub together.

Nuts are manufactured using a softer material than screws, so that if failure occurs, failure occurs in the nut and not the screw (which is the expensive member to replace).

Nuts are manufactured from plastic, bronze, or copper alloy. Plastic is often used in low-load scenarios and has good abrasion and wear properties. Bronze and copper alloys are commonly used for applications subjected to high loads.

Advantages of a lead screw

- Cost Less

- Self-Locking, Needs No Braking System

- Better For Vertical Applications

- High load-carrying capacity

- Compact

- Easy to design into a system

- Minimal number of parts

- Smooth operation

- Quiet

- Require little maintenance

Disadvantages of Lead Screw

- Require More Torque

- Require A Larger Motor And Drive

- Generate More Friction

- Generate More Heat

- Slower

- Less Efficient

- Shorter Lifespan

FAQs.

What is the difference between a lead screw and a threaded rod

Lead screws differ from threaded rods in that its purpose is the transmission of power rather than fastening. Because of this difference, the shape of a lead screw thread is not v-shaped or isometric.

These shapes lead to more friction, which is desirable in fastening but not when threads are made to allow for motion.

Pitch is the distance between a screw’s threads, whereas lead is the distance a screw will travel when turned 360 degrees. As previously mentioned, all screws have threading.

The way in which the threading is designed can affect both the pitch and lead. Pitch is simply a measurement of the distance between the threads.

What are the disadvantages of lead screws?

1. Require More Torque

2. Require A Larger Motor And Drive

3. Generate More Friction

4. Generate More Heat

5. Slower

6. Less Efficient

7. Shorter Lifespan

What is the difference between ball screw and lead screw?

One primary difference between a ball screw vs lead screw is that ball screws rely on ball bearings to reduce friction between the nut and screw, whereas lead screws do not.

On a ball screw, the nut and screw have matching helical grooves that permit ball bearings to re-circulate in the races, and they often have a semi-circular shape to accommodate the spherical ball bearing.

Lead screws rely on deeper helical threads and a mating nut that is typically constructed of bronze or a polymer composite. Unlike lead screws, ball screws exhibit a rolling nature that eliminates sliding friction.

It is critical to consider the advantages and disadvantages of each actuator before determining the ideal solution for an application. Consider your specific requirements and compare the characteristics to find the best fit.

How efficient are lead screws?

The efficiency of lead screws, on the other hand, typically ranges between 20% and 80%. The efficiency of a lead screw is highly dependent upon its helix angle. As a general rule, higher helix angles mean higher efficiency.

When would you use a lead screw?

They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides (such as in machine tools), vises, presses, and jacks. Leadscrews are a common component in electric linear actuators.

Do lead screws have backlash?

Backlash is an inherent property of lead screw assemblies due to the sliding motion between the screw and the nut.

You can see the space between the threads of rod and the threads of the nut. This space is called backlash. Backlash is a measurable quantity.

The simplest way to measure it in a screw and nut is to push the nut as far as it will go in one direction and then to measure how far it can move in the other direction.