What is a Bolt?

A bolt is a type of threaded fastener with an external male thread designed to fit into an existing female thread, typically a nut. Bolts are fundamentally similar to screws. In fact, the difference between the two is often very subtle.

A bolt is basically a shaft with threads and is used to join two or more parts. In order to use a bolt to assemble parts, the holes are aligned and the bolt shaft advances through the holes.

As a final assembly procedure, the nut is threaded onto the bolt to impose sufficient clamping forces to hold the assembly together and restrict unwanted movement along the axis.

The nut is threaded onto the bolt shaft. The threading of the nut creates enough clamping forces to hold the assembly together and restrict unwanted movement along the axis.

Some authors differentiate bolts and screws based on the use – bolts are designed to go through (unthreaded) holes, screws are designed to go into (sales have threads already formed within one of the parts) holes.

In practice, the difference is often not clear-cut, and it is common for people to refer to fasteners with threaded shafts as all “bolts” despite the fasteners function.

Bolts are purposefully designed to prevent radial (sideways) and axial (length-wise) movement of the pieces they fasten together. The section of the fastener which is without threads, (called the shank) is situated within the joined parts.

The smooth nature of the shank allows for a closer fit and creates less wear than the apparent threaded section. Importantly, the shank does not have the stress concentrations that the threads have.

Therefore, the bolt shank should extend well past the interface of the two parts, especially when the bolts are assumed to carry shear forces.

When a bolt is tightened, torque is applied to the head of the bolt, and an axial force is created between where the bolt head rests and the item it is being drawn against, which can either be a nut or one of the assembled parts.

As it is tightened, the bolt is being slightly stretched, and the parts being joined or being compressed together. Since it is common for bolts to start loosening with time advocation of some sort of locking nut or use of a thread adhesive is common also.

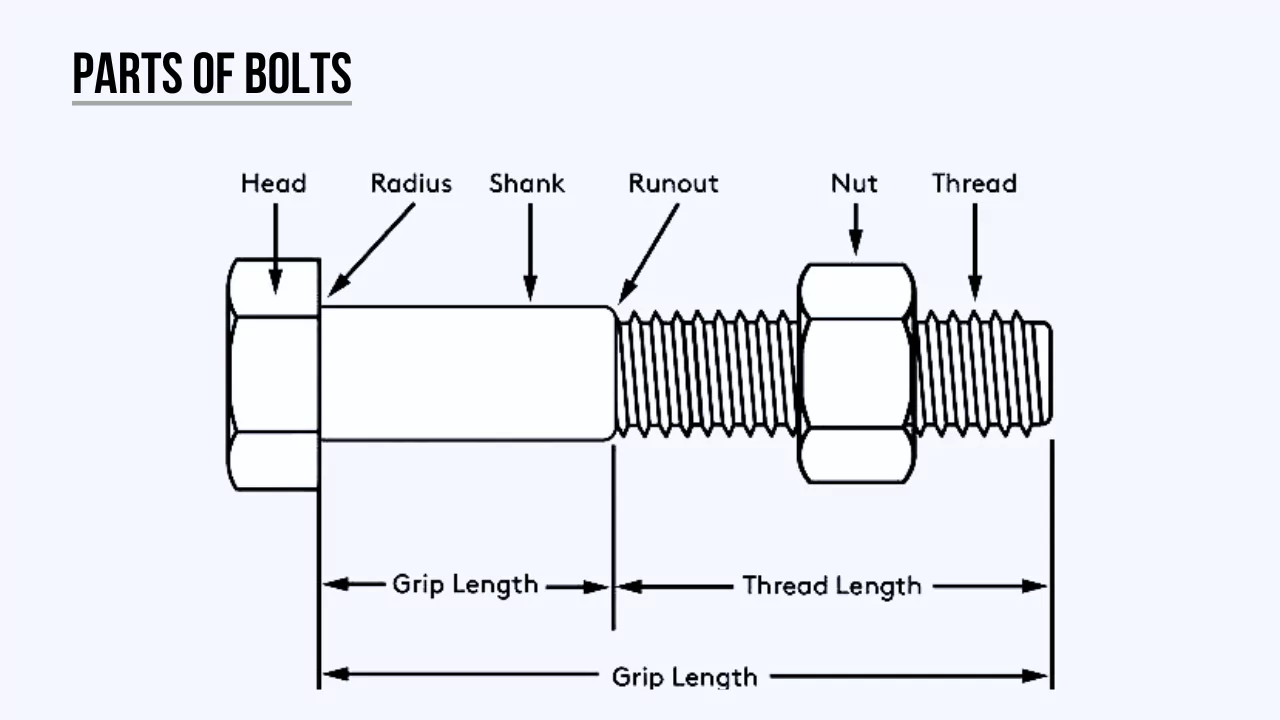

Parts of Bolt

These are different parts of the bolt described as follows.

- Head: The head is the section of the bolt that is most easily identifiable – it is the region furthest away from the plate or substrate the area intended for gripping with a tool – wrenches or spanners. When the time comes to apply force on the bolt, using a tool, it must use a snug fit on the head. Most heads are designed in the shape of a wrench, or similar tool, that makes it easier to apply torque without slipping off the head while sustaining torque.

- Shank: Just below the head, you will find the shank which is typically a smooth, or unthreaded area of the bolt. The shank has one primary function, prevent the joined items from moving sideways (along the radial axis). If a bolt does not have a shank it holds the potential risk of working loose over time, especially if the work pieces create vibrations or get picked up by their environment.

- Grip Length: The grip length is the part of the bolt that will be joining the parts together and is ideally the same length as all the material being joined. If the grip length is too short or too long, the connection won’t be as secure as intended.

- Threading: Threading is the signature feature of all bolts, the threads is what creates the ability to screw the bolt into, or out of the work pieces. It would also be prudent to mention that almost all bolts are not threaded all the way down their whole length. You will typically see the head, then a smooth shank area, then the threads.

- Thread Length: As mentioned previously, thread length is the section of the bolt that will accommodate a nut. It is wise to have the thread length appropriate for the application to provide a secure fit.

- Nominal Length: The nominal length of the bolt is simply the entirely the length of the thread length and grip length – displayed from the point under the head to the end of the threads in most technical drawings.

Difference between Bolts and Screws

A bolt is a fastener which utilizes its non-tapered shape, in combination with either a nut or washer to hold items together. The screw tapers to a point, and is designed either to turn into an existing thread, or to form its own thread in the item being fastened as it is being driven in.

Type of bolt heads

Fasteners have many different head shapes, and each shape is intended to engage a particular tightening tool. The shape of the head allows the tool to effectively grip the fastener while being installed.

Some of the more common choices for bolt head types are: square, hex, slotted hex washer and socket cap.

Square heads were used first in history. They have a square hole in the top of the bolt and a shaft that resists rotation when torque is applied. Square heads still exist today, however, hex heads have become the new standard as they allow for a more efficient application of torque using a wrench or spanner.

Again, there are many other shapes:

- Flat Bolt Head: The Flat bolt head, which has a flat surface and countersunk shape, will sit flush with the material when installed.

- Oval Bolt Head: The Oval bolt head is similar to a countersunk bolt head with a less pronounced rounded top.

- Pan Bolt Head: The Pan bolt head has a shorter vertical edge and has shallow or gentle curvature above the base, which provides strength and a clean look on the surface.

- Truss Bolt Head: The Truss bolt head is very wide in comparison to its rounded top; it spreads stress and distributes pressure over a larger surface area.

- Round Bolt Head: The Round bolt head, which is also known as a domed head, has an entirely smooth top that creates a plain shape that does not stand out.

- Hex Bolt Head: This bolt head is a six-sided (hexagon) shape that can easily be tightened using commonly available tools.

- Hex Washer Bolt Head: This head contains a hexagon base and a round washer under it to prevent movement, create extra stability and distributes the force applied more evenly.

- Slotted Hex Washer Bolt Head: This version is similar to a Hex Washer bolt head but it has the additional slot for a screwdriver but also contains a round washer and hexagonal rear face.

- Socket Cap Bolt Head: The Socket Bolt Head is a low-profile cylindrical designed to only be driven with a socket driver and is useful in applications with restrictions above.

- Button Bolt Head: This head takes on a low-profile shape with a rounded section combined with a socket drive. This shape is very attractive and holds up extremely well in applications.

Although bolts and screws have similar features, they are dissimilar. Machinery’s Handbook states that bolts join unscrewed parts, using a nut as an aid, while screws join parts that have internal threads.

However, it should be known that not all applications that use a screw involve pre-threaded materials; in some instances, the screw threads into the material making the threads as it is driven in.

What is a Bolt Used for?

Bolt uses the following conditions when:

- Bolted joints are particularly effective when components will require frequent disassembly and assembly.

- When the materials can not be joined with lasting threads, bolts are the best solution.

- These joints are the best option when the parts will be moderately thick—and beams, flanges, or plates are examples.

- Another consideration is will there be room to fit the both the bolt head and nut.

- Finally, it will be helpful to have enough space to turn a spanner to assemble and disassemble.

advantages and disadvantages of screws and bolts fastener

- On the whole, screws are usually less expensive than bolts.

- Bolts are more commonly used where the parts are to be repeatedly assembled and disassembled applications; screws would not be as good for the same situations.

- Another thing to consider is that bolts are designed to support loads on the larger shank area, so bolts are usually stronger than screws.

FAQs

Is A bolt a nut or a screw?

A bolt is meant to be used with a nut, and it is tightened by torquing the nut. A screw is designed to be used in either a preformed or threaded hole, or it is capable of forming its own threaded hole. A screw is designed to be tightened by torquing the head.

What is the definition of a bolt?

A metal rod or pin for fastening objects together that usually has a head at one end and a screw thread at the other and is secured by a nut.

Does a bolt have a head?

Bolts use a wide variety of head designs, as do screws. These are designed to engage with the tool used to tighten them. Some bolt heads instead lock the bolt in place, so that it does not move and a tool is only needed for the nut end. Common bolt heads include hex, slotted hex washer, and socket cap.

What are the three types of bolts?

Common Types of Bolts

1. Place bolts feature self-locking, free-spinning hex heads that prevent loosening due to vibration.

2. Carriage bolts feature reduced body diameters and enlarged, domed heads.

3. Hex bolts feature six-sided hex caps on one end.

What is a bolt without a nut called?

Lag Bolts: Also known as lag screws, not used with a nut. Extremely sturdy, good for bearing heavy loads.

Can you use a screw instead of a bolt?

Bolts vs. screws. The choice between using one or the other in a particular application depends on several factors. These include structural requirements, materials being joined, load-bearing capacity, ease of assembly, and the need for disassembly.