Metal inert gas welding is a process where a hand-held gun contains a spool-fed wire electrode, with a gas nozzle that delivers a stream of gas to the weld site to prohibit the contact of oxygen, nitrogen, and other gases in the environment with the weld bead, ensuring consistency of results and strength.

Contamination can lead to a low-quality weld on your workpiece, and for this reason, it is extremely important to select the correct gas for optimal results. But what is the optimal gas for MIG welding? Unfortunately, the answer does not come so easy.

Various metals need specific gases for optimal results, however, in most cases, a 75/25 argon and CO2 will allow you to get good results on most metals. But let’s take a look at some of your options now and discuss how you might select the preferred MIG welding gas for your job.

MIG Welding Gas – Choosing The Right Gas

The primary gas for MIG/MAG welding is argon (Ar). Helium (He) can be added to enhance penetration and fluidity of the weld pool. Argon or argon/ helium mixtures can be used for welding on any grade.

There are six noble gases, but for MIG welding we typically only consider argon and helium. Pure mixtures of argon/helium are typically only for welding nonferrous metals such as copper and aluminum. Argon and helium both appropriate for all processes in MIG welding, but argon is by far the most common gas for MIG.

Many MIG welding applications will have gas choices and you must frame those choices according to your welding objectives and welding applications. You should consider the following criteria when determining the right shielding gas exposure for your specific application:

- Gas cost

- Finished weld properties

- Preparation and post-weld clean-up

- Base material

- Weld transfer process

- Productivity objectives.

The four most commonly used shielding gases in MIG welding are Argon, Helium, Carbon Dioxide, and Oxygen. Each has its own unique advantages and disadvantages in any given application.

Carbon Dioxide (CO2)

Carbon dioxide is obtained from fuel gases-emitted from the combustion of natural gas, fuel oil, or coke. It can also be derived as a by-product from calcination process in lime kilns, from the production of ammonia, and from the fermentation of alcohol.

Carbon dioxide from the production of ammonia and the fermentation of alcohol is virtually 100% pure. When supplied to the user, carbon dioxide can be supplied in either cylinder or bulk form, with the cylinder being the most common.

With the bulk system, carbon dioxide is typically drawn as a liquid and converted to gas before going to the welding torch. The bulk system is usually used when there are a large number of welding stations that need to be supplied with carbon dioxide.

In the cylinder, carbon dioxide exists in both liquid and vapour state, with approximately two-thirds of the cylinder volume taken up by the liquid carbon dioxide. By weight, this is approximately 90% of the contents of the cylinder.

The gaseous portion of the cylinder consists of the vapour above the liquid. This gas will vapourize from the liquid when the vapour is taken from the cylinder, and it is this vapour that will pressurize the system, and the pressure gage will reflect the overall pressure from all the vapourization taking place in the cylinder.

The CO2 cylinder should be changed out for a new cylinder when the pressure in the cylinder has dropped to 200 psi (1.4 MPa). A positive pressure should always be left in the cylinder, however, it will help prevent moisture and other contaminants and have a tendency to back up into the cylinder.

Normal discharge rates of the CO2 cylinder are from about 4 to 35 cubic feet per hour (1.9 to 17 liters per minute). When using a single cylinder for welding, it will be recommended to use a maximum discharge rate of 25 cfh (12 l/min).

Vapor that drops from cylinder pressure to discharge pressure while passing through the CO2 regulator will absorb vast amounts of heat. If flow rates are set too high, enough heat will be absorbed that the regulator and flow meter will freeze up, disrupting the gas shielding.

When flow rates greater than 25 cfh (12 l/min) are needed, it is normal practice to manifold two CO2 cylinders in parallel or to heat the gas with a heater between the bottle and gas regulator, pressure regulator, and flowmeter.

Carbon dioxide has become a very common shielding gas for welding mild and low alloy steels. Except for argon which is a noble gas, most of the active gases cannot be used as shielding gasses. However, carbon dioxide has some benefits that make it useful for welding steel:

- Better penetration in the joint

- Higher weld speeds

- Lower welding costs (the very first benefit!)

Carbon dioxide creates short-circuiting transfer when using low current levels, and globular transfer at the higher current levels. As carbon dioxide is an oxidizing gas, almost all of the electrode wires for welding steel contain deoxidizers to combat porosity in the weld.

Often the surface of the weld bead will be somewhat oxidized even though there is no porosity. The main disadvantage of carbon dioxide is it generates a very harsh arc and will create higher amounts of spatter. It is usually desirable to use a short arc length to keep the amount of spatter to a minimum.

One additional problem with carbon dioxide is that it will add some carbon to the weld deposit. This will have little significance when welding mild steels.

However, this can lessen the corrosion resistance of stainless steels and lower the ductility and toughness of the weld deposit in some of the low alloy steels.

Argon

Argon shielding gas is chemically inert and is primarily used on non-ferrous metals. Argon is extracted from the atmosphere by liquifying air. It can be supplied as compressed gas, or as liquid argon which can be used if it is used often enough.

Argon shielding gas will tend to favour spray type transfer of metal at most currents. Argon is a heavier gas than helium; therefore the values of argon will produce lower gas flow rates, since the gas does not leave the weld area as readily as helium.

Argon also has the advantage of better draft resistance. For any arc length and welding current, the arc voltage is lower for argon than either helium or carbon dioxide.

This means that there is less arc energy therefore argon is more favourable in welding thin metal and welding metal with low thermal conductivity. Argon is also less expensive than helium and available in larger quantities. And argon provides better arc starting, quieter and calmer operation of the arc and cleaner action.

Oxygen

Oxygen, like the reactive gases discussed above, can be used in ratios of nine percent or less, to assist in creating an effective weld joint on mild carbon, low alloy and stainless steel.

Oxygen’s function in the welding process is to help improve weld pool fluidity, penetration, and arc stability of the weld. However, oxygen does cause oxidation of the weld metal, therefore it is not recommended for aluminum, magnesium, copper, or other exotic metals.

Helium

Helium shielding gas is inert and primarily used on aluminum, magnesium and copper alloys. It is low density and collected by separation from natural gas. It has both liquid and compressed gas forms in cylinders.

Because helium shielding gas is less dense than air, higher gas flow rates are required for sufficient shielding. Typical gas flow rates are 2-3 times the amount of argon shielding gas when utilizing flat position welding.

Helium is better to use in the overhead position, because the gas floats up and provides good shielding while argon typically floats down.

Globular transfer of metal is often really easily done with helium. While less common, it is entirely possible to get spray transfer at the highest levels of current.

That being said, it can be expected to create more spatter and lesser weld beads when using helium compared to argon.

For same arc length, and current level helium produces hotter arcs than argon making it good for welding thick metal and also highly conductive materials such as copper, aluminum, and magnesium.

In comparison, helium shielding gas chimes produce wider weld beads and greater penetration compared to argon of similar flows.

Argon-Helium Mixtures

Regardless of proportions, argon-helium mixtures are applied to non-ferrous materials such as aluminum, copper, nickel alloys, and reactive metals.

The gases in varied combinations, increase arc voltage and heat for GTAW and MIG while retaining the beneficial behaviors of argon.

The general rule is the heavier the material the higher the percent helium you would use. Very small helium percentages, as low as 10%, will affect the arc and the mechanical properties of the weld.

As the percentage of helium increases, the arc voltage and spatter and penetration will increase while minimizing porosity. A pure helium gas will broadens the penetration and bead but the depth of penetration could suffer. However, there is still an increase arc stability.

There must be at least 20% argon when mixing with helium in order to produce and control the spray arc stability.

- Argon – 25% He (HE-25): This rare mixture is sometimes recommended for welding aluminum where increased penetration is desired and bead appearance is of utmost consideration.

- Argon – 75% He (HE-75): This common mixture is very utilized in mechanized welding of aluminum greater than 1 inch thick and in the flat position. HE-75 also increases the heat input and reduces porosity of welds of ¼-and 1 ½- in. thick conductive copper.

- Argon – 90% He (HE-90): This mixture is utilized for welding copper greater than ½ inch thick and aluminum greater than 3 inches thick. The increased heat input improves weld coalescence and has good x-ray quality. It is also utilized for short-circuiting transfer with nickel filler metals.

Argon-Oxygen Mixtures

Gas mixtures of argon-oxygen typically have 1%, 2% or 5% oxygen. The small amount of oxygen in the gas makes the gas slightly oxidizing, thus the filler metal used must have deoxidizers to remove oxygen from the weld puddle and avoid porosity.

Argon alone does not often produce the best arc characteristics when welding ferrous metals. In pure argon shielding the filler metal does not always wet out to the fusion line.

The inclusion of small amounts of oxygen to argon greatly stabilizes the weld arc, increases the droplet rate of the filler metal, decreased the current at the spray arc transition point, and increased wetting and bead shape.

The weld puddle is more fluid and remains molten longer, allowing the metal to flow out toward the toe of the weld, lessening the undercutting and helping to flatten the weld bead.

There have been instances when small amounts of oxygen have been added for non-ferrous applications. For example, NASA has reportedly found .1% oxygen useful to stabilize arcs when welding very clean aluminum plate.

Argon-1% O2:

This mixture is mainly used for spray transfer on stainless steels. One percent oxygen is usually sufficient to stabilize the arc, increase droplet rate, provide coalescence, and improve appearance.

Argon-2% O2:

This mixture is used for spray arc welding on carbon steels, low alloy steels and stainless steels. It provides additional wetting action over the 1% O2 mixture. Mechanical and corrosion performance of welds made with 1 and 2% O2 additions are equivalent.

Argon-5% O2:

This mixture provides a more controllable but fluid weld pool. It is the most common argon-oxygen mixture to use for general carbon steel welding. The added oxygen allows higher travel speeds.

Argon-8-12% O2:

This mixture was originally introduced in Germany, and has recently been seen in the U.S. in 8 and 12% revision types. The primary uses are for single pass applications, but a few multi-pass applications have been noted.

The higher oxidizing potential of these gases must be considered with regard to the wire alloy chemistry. In some cases, a higher alloyed wire may be needed to make up for the reactive shielding gas.

The greater weld puddle fluidity and lower spray arc transition current may have some benefits on some weld applications also.

Argon-12-25% O2:

Mixtures with very high amounts of O2 have been used on a limited basis, but the advantages of 25% O2 versus 12% O2 are arguable. Extreme fluidity of the puddle will be characteristic of this gas. Heavy slag/scaling on the surface of the bead can be expected, and is difficult to remove.

Provided care and a deoxidizing filler metal are used, sound welds can be made at the 25% O2 level with little or no porosity. It is preferable to remove the slag/scaling before weld passes to produce the best weld.

Argon-Carbon Dioxide Mixtures

Argon-CO2 mixtures are mainly utilized on carbon and low alloy steels; stainless steels are limited to small quantities. Argon additions to CO2 generally reduce the spatter levels associated with pure CO2 mixtures.

Small amounts of CO2 added to argon have a similar affect on the spray arc as small amounts of oxygen. The difference primarily being the much higher spray arc transition currents of the argon-CO2 mixtures.

In MIG welding with CO2 additions, the current level must be slightly higher to achieve stable spray transfer of metal across the arc effectively. The oxygen additions, on the other hand, reduced the spray transfer transition current.

Spray transfer would obviously become unstable above approximately 20% CO2 where random short circuiting and globular transfer occur.

Argon-3-10% CO2:

These mixtures would be a versatile mixture used for spray arc and short-circuiting transfer for a breadth of carbon steel thicknesses since the mixtures can utilize both arc modes effectively. All of these reasons mention make this gas mixture a widely applied argon-CO2 gas.

A 5% mixture is much more widely used for pulsed MIG welding of heavy section low alloy steels for welding out-of-position.

The welds are generally less oxidizing than the Ar-98%-O2-2% welds. Using CO2, the welder finds improved penetration has been achieved with less porosity than that of O2 additions.

In the case of bead wetting, it takes about twice the amount of CO2 to get the same wetting action as for the activities of equal amounts of O2. With 5-10% CO2, the arc column becomes very stiff and well-defined.

The strong arc forces generated provide these mixtures greater tolerance for mill scale, and allow for a puddle that can be very tightly controlled.

Argon-11-20% CO2:

This mixture range has been used for various applications in narrow gap, out-of-position sheet metal, and high speed MIG applications. Most work has been done on carbon and low alloy steels. By varying the CO2 in this range, you can achieve higher productivity on thin gauge materials.

This is accomplished by limiting burn through potential while maximizing deposition and travel speeds. The lower CO2 percentages also improve deposition efficiency by mitigating spatter loss.

Argon-21-25% CO2:

Used almost exclusively with short circuiting transfer on mild steel, originally developed to maximize the short circuit frequency on .030 and .035 in diameter solid wires but over the years became the de facto standard for most diameter solid wire welding, and has commonly been used with flux cored wires.

The mixture also behaves well in high current, large duty-cycle applications on heavy materials and can have good arc stability, puddle control and bead appearance as well high productivity.

Argon-50% CO2:

This mixture is used when high heat input and deep penetration is required. Recommended material thickness are above 11/8 in., and out-of-position welds can be made. This mixture is a very popular mixture for pipe welding using the short-circuiting transfer.

The main advantages for the pipe welding application are good wetting and bead shape without excessive puddle fluidity. Thin gauge materials have more chance of burn through, which may limit the overall versatility of the gas.

When welding at high current levels, the metal transfer is aligned (more consistent) with welding in pure CO2 than the previous mixtures, but some reduction in spatter loss can be achieved with the argon addition.

Argon-75% CO2:

A 75% CO2 mixture is used in some heavy wall pipe applications and is optimum in good side-wall fusion and deep penetration. The argon component helps in stabilizing the arc and reducing spatter.

Helium-Argon-Carbon Dioxide Mixtures

The three-part shielding gas blends continue to be utilized for carbon steel, stainless steel, and limited applications of nickel alloys.

The addition of 40% helium to argon and CO2 as the third component to the shielding gas blend for short-circuiting transfer on carbon steel offers a wider penetration profile.

Helium provides more thermal conductivity for short-circuiting transfer for carbon steel and stainless steel base material.

The wider penetration profile and increased side wall fusion reduce the likelihood of undercut and incomplete fusion for stainless steel applications where three-part mixes are common.

Helium increments of 55% to 90% in addition to argon and 2.5% CO2 is often used for short-circuiting transfer. Helium shielding gas mixes are preferred because of reduced spatter and puddle fluidity, and a flatter weld bead shape.

Common Ternary Gas Shielding Blends

90% Helium + 7.5% Argon + 2.5% CO2: This is the most widely used of the short-circuiting blends used for stainless steel applications. The high thermal conductivity of helium allows for a flat bead shape and an excellent fusion. This blend has also been adapted for use in pulsed spray transfer applications, but again only on stainless or nickel base materials that are greater than .062–in. (1.6 mm) thick. It is characterized by having high travel speeds in stainless steel applications.

55% Helium + 42.5% Argon + 2.5% CO2: Although not as popular as the 90% helium blend described above, this blend has a cooler arc for pulsed spray transfer, and it also supports very well the short-circuiting mode of metal transfer for stainless and nickel alloy applications. The lower percentage of helium allows for use with axial spray transfer.

38% Helium + 65% Argon + 7% CO2: This tertiary blend is for use with short-circuiting transfer in mild and low alloy steel applications. It is also applicable to pipe with an open-root weld. The high thermal conductivity broadens the penetration profile thereby reducing the possibility of cold lap.

Other Gases

Hydrogen is an effective shielding gas in high temperature applications energy source, for example, when mixed with argon used on stainless steel.

Nitrogen is used as a purging gas in through-purging of stainless steel tube welding. Nitrogen can also be mixed to argon as a small amount of shielding gas for stainless steel applications.

Propane is typically used as a cutting gas, in scrap yards, which cuts carbon steel, while cut quality does not matter. If your application does not require high cut quality, propane is the economical choice.

What’s the Best Gas for MIG Welding Different Metals?

The baseline gas for MIG/MAG welding is argon (Ar). Helium (He) can be added to increase penetration as well as the fluidity of the weld pool. Argon or argon/helium mixtures can be used for welding all grades.

If you’re looking for a “one-size-fits-all” a MIG welding shielding gas with a 75/25 mix of argon and CO2 may be your best option.

At Vern Lewis Welding Supply we have a high-quality 75/25 argon and CO2 mix that is a great value to weld most of the metals, mild steels as well as nonferrous metals as it is a cost effective consumable.

Conclusion: How to Choose the Best Gas for MIG Welding

If you are looking for the top gas to utilize for MIG welding with a wide application, the 25% carbon dioxide and 75% argon, or anything similar to that as in an 80/20 mix would be about your best choice.

If you are on a budget and don’t mind cleanup from a little extra spatter, carbon dioxide is very inexpensive and enough, in conjunction with your gas, to experiment and do hobby welding. For MIG welding aluminum, or usually for TIG welding, 100% argon is best.

With stainless steel things get more pricey to mix in more helium with either argon and carbon dioxide or Oxygen. There you might also select a cheaper C2 which is a 98/20 mix.

Always consider the metals you are welding and you want to maximize your gas flow. Remember also that, while your gas selection and gas flow rate will help give you a consistent bead pattern and avoid overheating your metal, the most consistent shaped bead, or similar pattern, will be accomplished with consistent gas flow.

FAQs

What gas bottle is used for MIG welding?

Argon is the most commonly used inert gas in welding applications due to its affordability and effectiveness. Helium, although more expensive, is sometimes used for specific applications that require higher heat input.

What type of gas is used for welding?

Gases used in welding and cutting processes include: shielding gases such as carbon dioxide, argon, helium, etc. fuel gases such as acetylene, propane, butane, etc. oxygen, used with fuel gases and also in small amounts in some shielding gas mixtures.

Why is CO2 used in MIG welding?

Carbon dioxide improves weld speed, penetration and mechanical properties that make it the most suitable for steel in metal inert gas (MIG) welding. However, this gas also causes a shakier arc, spatter losses and a lot of smoke fumes. Mixing carbon dioxide with argon minimises the spatter.

What type of gas is best for MIG welding?

MIG Gases. If you’re going to be MIG welding, there are two main gases that are used: pure argon and an argon/carbon dioxide mix. The most common (and recommended) Ar/CO2 mix is a 75/25 ratio, with 75% of it being argon and 25% of it being CO2.

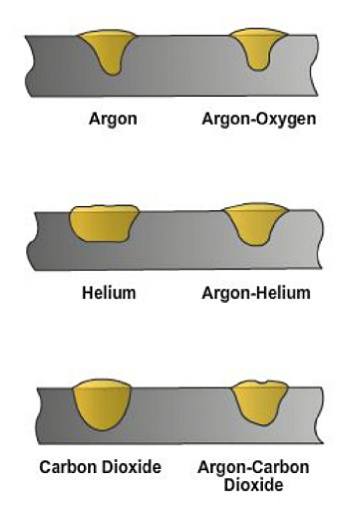

Is argon or CO2 better for MIG welding?

Pure argon (an inert gas) gives shallow penetration but a wider bead profile in a weld. It also results in less spatter. CO2 (a semi-inert gas) can be used on its own, as it gives deeper penetration than argon (plus it’s cheaper). However, it produces a harsher, less stable arc, which results in a lot of spatter.