What Is Gas Tungsten Arc Welding (GTAW)?

Gas tungsten arc welding (GTAW), also referred to as tungsten inert gas (TIG) welding, is an arc welding process where a non-consumable tungsten electrode creates the weld. Argon or helium gas is used to shield the weld area from oxidation or other atmospheric contamination.

Filler metal is typically added, but not required for some welds in the category of autogenous welds, or fusion welds. Helium can be used in place of argon, and this is known as heliarc welding.

A welding power supply provides a constant-current source which generates electrical energy that is transmitted through an arc by a column of highly ionized gas and metal vapors known as plasma.

GTAW is most frequently used for welding thin sections of stainless steel and non-ferrous metals (aluminum, magnesium, copper alloys).

The GTAW process allows for better control of the weld than other processes, such as shielded metal arc welding and gas metal arc welding, resulting in stronger, higher-quality welds.

However, GTAW is more complicated and difficult to learn, and is also slower than most welding technologies. A similar process, plasma arc welding, uses a slightly different welding torch to produce a more concentrated welding arc, and is usually automated.

How Does A Gas Tungsten Arc Welding Work?

Manual gas tungsten arc welding is a relatively complex welding process, due to the level of coordination needed by the welder.

Similar to torch welding, GTAW typically requires two hands, as in most applications the welder must take the filler metal and simply feed it into the weld area with one hand, while simultaneously manipulating the welding torch with the other hand.

Maintaining a stiff, short arc length while avoiding contact between the electrode and the work piece is important.

In order to strike the welding arc, a high frequency generator, which operates similarly to a Tesla coil, creates an electric spark that establishes a conductive path for the welding current through the shielding gas, allowing for the arc to be started with the electrode and the work piece separated by a distance that is typically about 1.5 – 3 mm (0.06 – 0.12 in.).

Once the arc is struck, the will usually move the torch in a small circular motion to create the weld pool, and the size of the weld pool usually depends on the size of the electrode used and the amount of current applied.

While maintaining the constant separation distance from the work piece to the electrode, the operator will move or “push” the torch back slightly, while tilting it in a backward motion about 10 – 15 degrees off vertical. Filler metal will be added manually to the front end of the weld pool, as the need arises.

Welders frequently develop a technique of rapidly switching back and forth between moving the torch forward (to effectively advance the weld pool) and adding filler metal.

The filler rod is always retracted from the weld pool after each advance of the electrode but it is always kept inside the gas shield to prevent oxidation of its surface and contamination of the weld.

Filler rods that are constructed with metals that have a low melting temperature, such as aluminum, require the operator to maintain some distance from the arc but always stay within the gas shield, because if they hold it too close to the arc the filler rod can melt before the rodd contacts the weld puddle.

As the weld nears completion, the arc current may be gradually decreased as the weld crater is allowed to solidify in-situ to minimize the potential for crater cracks developing at the end of the weld.

Shielding gas use in Gas Tungsten Arc Welding

Shielding gas is selected according to the material being welded. The following guidelines may help:

- Argon: The most commonly utilized shielding gas with the ability to weld steel and other various types of metals, including stainless steel, aluminum, and titanium.

- Argon + 2 to 5% H2: Adding hydrogen to argon will make the shielding gas slightly hotter, allowing cleaner-looking welds with less surface oxidation. Since the arc is hotter and more constricted, it allows for higher welding speeds. Some disadvantages include hydrogen cracking on carbon steels and weld metal porosity on aluminum alloys.

- Helium and helium/argon mixtures: Adding helium to argon will create a hotter arc, which allows for higher welding speeds and deeper weld penetration. The disadvantages of using helium or helium/argon mixtures are the cost of gas and the difficulty in starting the arc.

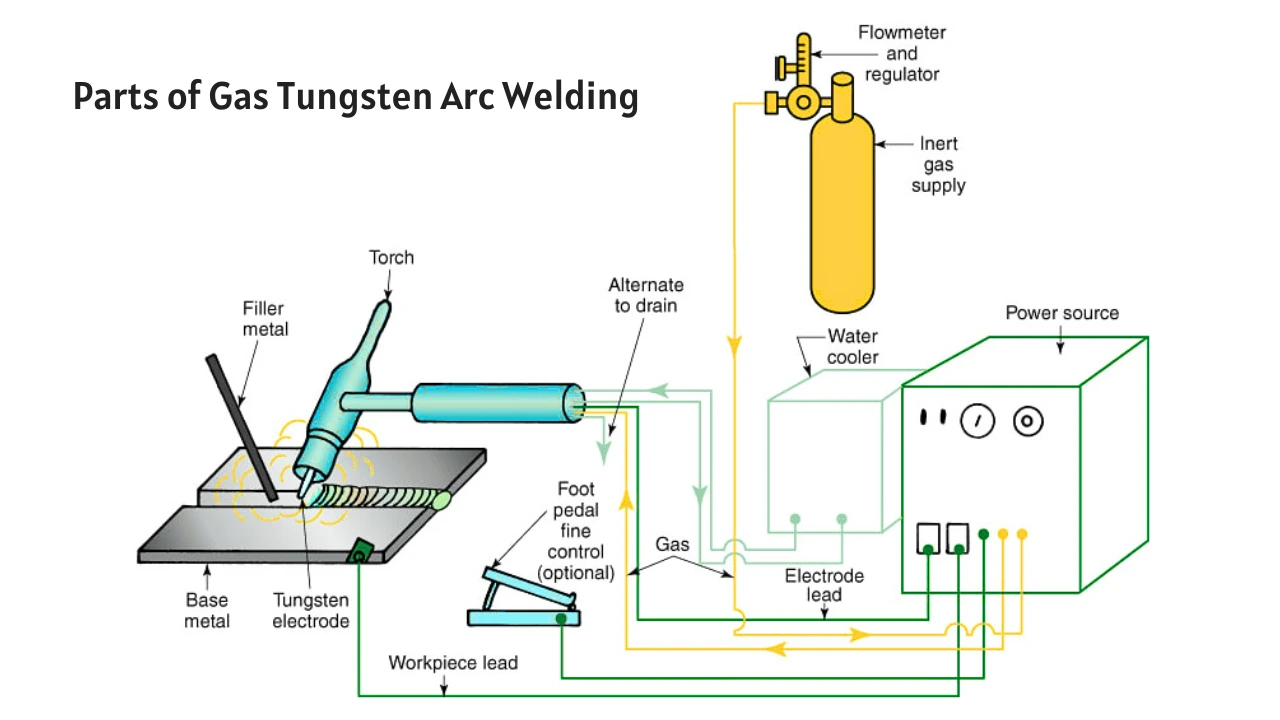

Construction Or Parts of Gas Tungsten Arc Welding

A Tungsten Inert Gas Welding Machine consists of the following equipment:

- Power Supply

- Inert Gas Supply

- Welding Torch/Holder

- Tungsten Electrode

- Shielding Gas

- Filler Rod

1. Power Supply:

The welding process of TIG must have a constant power supply mainly for the reasons when current varies, it can become difficult for the welder to weld properly.

There are two types of power supply:

- DC Power Supply

- AC Power Supply

With the DC power supply, we can weld steel, nickel, titanium, etc. and with the AC power supply, we can weld magnesium, aluminum, etc.

2. Inert Gas Supply:

For tungsten inert gas (TIG), we need a supply of inert gas to provide shielding to the weld area from atmospheric gases (Oxygen, Nitrogen, and Hydrogen).

Typically, argon is used as the inert gas supply in TIG. We will cover in a later section on shielding gas.

3. Welding Torch:

Under the TIG Welding heading, the welding torch has been manufactured for either automatic or manual operations, although equipment wise, there is not really any difference between the two.

The manual torch will have an operation, which the operator will hold in their hands, the automatic torch will have the function of being mounted to an automatic machine.

Either way, torches can have a cooling system using air and water.

For example, if the Ampere rating of the current is less than 200 A generally, we use air-cooling, and if the Ampere exceeds 200 A, we would generally use water-cooling system to lower the temperature of the welding torch.

The inside body of a welding torch is also generally made of copper, this is used to improve thermal conductivity.

And a torch will be outfitted with a holding apparatus (Port) to hold the tungsten electrode in place.

4. Tungsten Electrode:

In the TIG Welding process, we use a non-consumable electrode comprised of Tungsten, or Tungsten Alloy.

Tungsten is used for the non-consumable electrode due to its high-temperature resistance capacity (the Melting Temp of Tungsten is 3,422 °C) as opposed to any other metal.

Generally, the electrode diameter ranges from 0.5 mm to 0.65 mm, and the length varies from 75 mm to 610 mm.

5. Shielding Gas:

Shielding gases minimize the effect of atmospheric gases such as nitrogen, oxygen, etc., that can create porosity, blowhole, and other defects on the welding surface.

Shielding gas options depend on the type of welding, the atmospheric condition, type of metal, etc.

In general, Argon is used as a shielding gas in TIG Welding. Sometimes Argon-helium mixtures are used in TIG welding as well.

6. Filler Rod:

As we know, in TIG Welding we use a non-consumable electrode which is Tungsten, so in some occasions, we will need to have separate material to fill up the gap between two joints.

The filler rod can be any material like carbon steel, aluminum, etc. It usually depends on the joint type, work-piece material, thickness and the properties of the workpiece.

Applications of Gas Tungsten Arc Welding

- This is particularly useful for welding refractory, reactive and sheet materials- the examples below highlights specific areas using TIG.

- Because Tungsten Gas welding can be applied to such a wide variety of metals, the process is utilized in many industries and used to manufacture and repair many products. Industries such as aerospace, automotive, repair and art all utilize this type of welding.

- Aerospace: Aircrafts and spacecrafts are built through TIG welding.

- Automotive: The automotive industry has a responsibility to build safe, secure products that will hold up for years to come.

- Repair: There are numerous repair applications that TIG can be used for. From the repair of a child’s wagon or pedal car to an aluminum tool repair, TIG is beneficial in many applications.

Advantages of Gas Tungsten Arc Welding

The advantages of Tungsten Inert Gas Welding are the following:

- Tungsten welding provides an option to weld critical joints, and for instances where small or very precise welds are needed.

- It can be done with many different types of metals

- And, when performed correctly, gives you a higher quality and higher purity weld than other joint processes, which is important in applications for many.

- It can be done either automatically, or manually.

- In general, it is one of the most efficient ways to join two metals.

- There is no slag produced.

- TIG Welding can be done in any position.

Disadvantages of Gas Tungsten Arc Welding

The disadvantages of TIG Welding are mentioned below:

- The tungsten welding cannot be done for a thicker sheet of metal.

- You will need Certified Welder and skilled workers.

- Safety issue, welders can experience high intensity lights, which can result in eye damage.

- The cost of TIG welding services are high. The cost will depend on what material is being welded and the size of the project.

- It is a slow process of welding.

FAQs

What is gas tungsten arc welding used?

Gas Tungsten Arc Welding is most commonly used to weld stainless steel and nonferrous materials, such as aluminum and magnesium, but it can be applied to nearly all metals, with a notable exception being zinc and its alloys.

What is the advantage of gas tungsten arc welding?

With GTAW, there is virtually no welding smoke or residue. Most metals can be welded with GTAW/TIG, even in the case of heterogeneous basic materials: stainless steel, titanium, magnesium, aluminium and copper. GTAW is a stable process and can be automated and applied in all welding position

What is the temperature of gas tungsten arc welding?

The GTAW process can produce temperatures of up to 35,000° F (19,426°C). The torch contributes heat only to the workpiece.

What is tungsten welding used for?

Pure tungsten was used as a welding electrode at the beginning of the TIG process, back in the 1940s. TIG welding was developed to efficiently join aluminum and magnesium alloys, and pure tungsten made sense at the time, since it has the highest melting temperature of all metals.

What are the hazards of gas tungsten arc welding?

Radiation burns to eyes or body. Body burns due to hot or molten materials. Flying sparks. Fire.

What is the difference between metal arc welding and tungsten arc welding?

Just like in GMAW welding, an inert shielding gas is used. But unlike GMAW, which uses a wire that also acts as filler material, GTAW heats up objects by utilizing a tungsten electrode that delivers current to the welding arc. This welding arc melts the metal and creates a liquid pool.