Pliers are one of those tools that prove their worth time and time again—especially when you run into an unexpected repair. Sure, you’ll find some pliers that are built for specific, almost niche jobs, but that’s exactly why it makes sense to have a variety of them on hand. If you keep a few different kinds in your toolbox, you’ll save yourself a lot of hassle when those unique repair situations pop up.

Let’s be real: not everyone keeps a pair of pliers at home, but honestly, everyone probably should. Even if you’ve just got a basic slip joint pliers stashed somewhere in a kitchen drawer, you’ll thank yourself when something needs fixing. They’re one of those unsung heroes that make all the difference for quick DIY repairs.

And then, of course, there’s the sheer variety of pliers out there. Some of us stick to just one or two pairs, while others—especially if you’re into specific hobbies or work in a trade—might have tools most people have never even heard of. You might read about a certain kind and think, “Wait, that’s a thing?” or even catch yourself wondering if you need to pick up a set for yourself.

The interesting thing is that while a lot of pliers can handle the same sorts of jobs, some are made for tasks so unique, only a handful of people ever use them. In the end, building up a small collection means you’re ready for just about anything that comes your way.

- Pliers serve as versatile tools, capable of handling a broad range of tasks—from installing and shaping wire to tightening or loosening nuts and bolts, pulling out nails, and performing many other functions around the workshop or home.

- It is important to recognize that not every type of plier is intended for electrical applications. If you anticipate working with or near electrical wiring, always check that the plier handles are insulated to reduce the risk of electric shock.

- When working with polished pipes, take a moment to wrap a cloth around the surface before gripping it with pliers. This simple precaution helps prevent scratches or other damage to the finish.

- Resist the temptation to use lightweight pliers for tasks that require more strength; heavy-duty jobs call for tools that are up to the challenge.

- Whenever possible, opt for wrenches or other specialized tools to turn nuts and bolts, as they are typically better suited to the task than pliers.

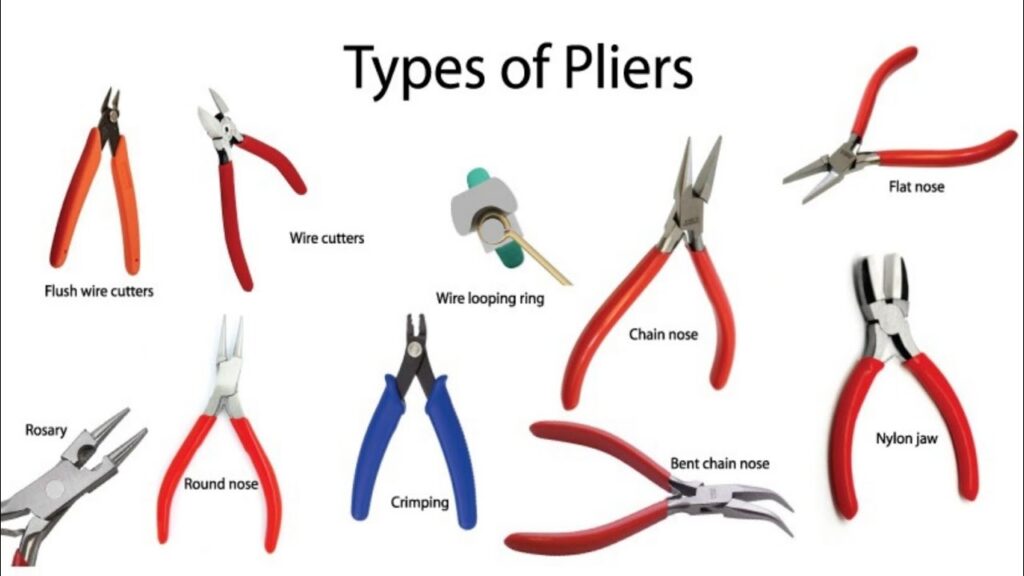

This guide highlights the different types of Pliers, along with the uses of each.

Anatomy of the Pliers

Combination pliers get their name from the fact that they’re designed to tackle more than one task. Thanks to their specially shaped jaws, these pliers can grip objects securely and also cut through materials like wire. Some versions even come with extra features, especially when they’re meant for a particular trade or specialized job.

- Handles: Most combination pliers have handles coated with plastic, which not only makes them more comfortable to hold but also helps prevent slips during use. The size and shape of the handles are closely tied to what the tool is intended for. For instance, high-leverage pliers have noticeably longer handles than the standard type, making it easier to apply more force with less effort. Electricians and linemen, on the other hand, usually rely on pliers with insulated handles. These are often certified by organizations like VDE, which is a respected authority when it comes to electrical safety standards.

- Jaws: The jaws are the business end of combination pliers. They move in sync with the handles, and their design lets you get a firm grip on various objects. Most jaws feature flat, often serrated edges to help keep things from slipping, though some might be smooth depending on the model. Typically, the tips of the jaws are squared off for better control.

- Cutters: Right near the pivot point of the pliers, you’ll find a set of cutters built into the jaws. This positioning isn’t an accident—it gives you the most leverage, making it much easier to snip through wire or cable. These cutters aren’t really intended for cutting sheet metal; they’re best used for cables and wires.

- Pipe grip: Another handy feature on many combination pliers is the pipe grip—a rounded, serrated cut-out in the jaws. It’s designed specifically for grabbing onto round items like pipes or thick cables. The shape helps to avoid squashing what you’re working on, which can happen with flat jaws. It’s worth noting, though, that not every pair of combination pliers includes a pipe grip.

- Pivot point: Finally, there’s the pivot point—the simple hinge that brings the whole tool together. This joint lets the handles and jaws move in unison, allowing you to open and close the pliers to grip or cut as needed.

Types Of Pliers

Learn more about the types of pliers and the different jobs they perform.

1. Crimping Pliers

Crimping tools, often referred to simply as crimpers, operate with a fulcrum positioned near the end of the handles—similar to the mechanism you’d find in a traditional nutcracker. The basic process involves inserting a wire into the tool’s jaw, followed by attaching a suitable connector.

As you press the handles together, the tool applies enough pressure to pierce the plastic insulation and reshape the metal components. This action binds the wire and connector securely, creating a reliable path for electrical signals or data transmission.

In practice, crimping tools are widely used in telecommunications and networking fields, where solid connections are crucial for signal integrity. For automotive applications, terminal crimpers are the go-to choice, while in computing environments, R145-type crimpers are especially common.

2. Diagonal Pliers

These tools are known by several names, including flush-cut pliers, diagonal-cutting pliers, and wire cutters, among others.

What sets these pliers apart is the angled design of their jaws, which allows them to cut through even relatively thick wires with ease. Their robust construction also means they can handle tougher jobs, such as cutting nails when needed. As a result, you’ll often find them used not only in electrical work but also in carpentry settings.

3. Hose Clamp Pliers

These tools are often referred to as hose pliers, radiator hose pliers, or spring clamp pliers. They’re specifically designed to compress spring and hose clamps, ensuring a more secure connection. Because they’re built for this purpose, you’ll find that they come in a variety of designs.

One of the most recognizable versions features peg-shaped teeth on each jaw, which are perfect for pinching clamps into place. Depending on the model, some can even be used directly on hoses themselves.

4. Needle Nose Pliers

Needle-nose pliers are essentially a smaller, more precise version of standard electrician’s pliers. Their long, slim jaws taper to a fine point, making them ideal for jobs that involve maneuvering wire or small parts inside tight spaces—like the inside of an electrical box.

I find them especially handy when you need to reach into cramped areas where your fingers just won’t fit. Besides handling wire, these pliers are surprisingly versatile; they’re great for bending, holding, or positioning small metal fittings.

If you look closely at the jaws, you’ll notice that the tips are serrated. This textured surface provides a firmer grip on whatever you’re holding. Down near the pivot, there’s a side cutter built right in, which can come in handy for snipping wires without switching tools.

You might also hear people call them “radio pliers,” which just hints at how often they’re used in electronics work. Personally, I’ve found them invaluable for dealing with tiny nuts, washers, and other small hardware especially when precision placement is key and my hands just aren’t steady enough on their own.

Some versions even have the tips bent at a 45 or 90-degree angle, which really helps when you’re working at an awkward angle.

One important thing to keep in mind: needle-nose pliers aren’t designed for heavy-duty work. They’re a delicate tool, and if you push them too hard, the jaws can easily get bent, sprung, or even break. So it’s best to reserve them for those light, detail-oriented tasks they’re meant for, rather than trying to muscle through tougher jobs.

5. Slip Joint Pliers

Often referred to as water pump pliers, slip-joint pliers are closely associated with adjustable wrenches, distinguished by a movable fulcrum that enables users to change the width of the jaws. This feature enhances their adaptability for various tasks.

For many people—myself included—slip-joint pliers were the first type of pliers encountered. It was only with experience that I realized the vast array of plier types available, far outnumbering the children in my neighborhood growing up.

While slip-joint pliers may not offer the pinpoint accuracy of more specialized tools, their everyday utility quickly becomes apparent. Whether it was adjusting a bicycle, repairing a wobbly kitchen stool, or tackling a minor electrical fix, these pliers found their way into many household jobs.

The practical uses for slip-joint pliers are extensive. They are especially useful for gripping and bending both flat and round materials, crimping sheet metal, forming wire loops, cutting softer wire nails, pulling out cotter pins, and even loosening or tightening nuts when a wrench is out of reach.

The central innovation of this tool lies in its slip joint—hence the name. Like other pliers, their operation relies on squeezing the handles to open and close the jaws.

What sets slip-joint pliers apart, however, is the adjustable pivot point. This allows the jaws to shift relative to each other, making it possible to grip objects of varying thicknesses, from a thin sheet of paper to something approaching half an inch, depending on the plier’s size.

Most slip-joint pliers are designed with two or three different positions for setting the pivot point, giving users a level of flexibility that makes these tools invaluable for a wide range of tasks.

6. Snap Ring Pliers

These pliers go by several names you might hear them called retaining ring pliers, lock ring pliers, circlip pliers, or even C-clip pliers. What sets them apart is their round, stubby jaws, which are specifically designed for working with snap rings.

If you’ve ever handled one of these rings, you’ll know they’re essentially loops with open ends, and they’re made to slot neatly into grooves on round objects like dowels.

The idea is pretty clever: once you close the snap ring into place, it’s able to spin or rotate without any trouble, but it can’t move side to side.

That little detail is why you’ll often find these rings and the pliers that go with them on things like the gears of mountain bikes. They keep everything securely in position without restricting necessary movement.

7. Tongue & Groove Pliers

Commonly referred to as channel locks, these pliers are designed with adjustable jaws, thanks to a series of toothed grooves along the upper handle. This feature lets you lock the lower jaw into different positions, making the tool quite versatile. The jaws themselves are set at an angle, which comes in handy when you need to grip or turn bolts and nuts securely.

8. Bail Making Pliers

This tool features a pair of jaws made from two dowels one noticeably larger than the other. It’s a staple in jewelry making, as the wire can be easily wrapped around the different-sized jaws to create clasps, ear wires, and a wide variety of looped components. The design makes it especially useful for shaping wire into precise and consistent forms, which is essential for professional-looking jewelry.

9. Battery Pliers

You’ll most often see these pliers in the automotive world, especially when it comes to handling bolts on car batteries or tightening up jumper cables. What really sets them apart is their short, angled jaws one of which is just a bit smaller than the other. Both jaws are built thick, giving them the extra durability needed to stand up to repeated use in tough conditions.

10. Bent Nose Pliers

Another variation of needle-nose pliers features jaws that bend at the midpoint, typically forming either a 45-degree or a 90-degree angle. This unique design makes it easier to grasp objects in tight or awkward spaces, especially in situations where using standard needle-nose pliers just isn’t practical. The angled jaws also allow you to work alongside other tools without them interfering with each other.

These angled needle-nose pliers come in handy for tasks like electrical work, jewelry making, or any job that involves shaping wire. Their shape gives you better access and control when dealing with materials that are otherwise difficult to reach.

11. Brake Spring Pliers

In the field of automotive repair, several specialized tools have been developed for managing drum brake springs. Typically, these tools are designed with two distinct jaw tips: one is rounded, making it easier to remove the springs, while the other is curved to facilitate reinstalling them.

Additionally, some versions incorporate a ratcheting mechanism on one of the handles, which proves useful when removing shoe hold-down pins.

12. Canvas Pliers

These wide-jawed pliers are a real game-changer for artists working on canvas. Instead of needing a second pair of hands, one person can easily handle the task of stretching canvas onto a frame.

The jaws themselves are typically padded, which is important they help protect the surface of the canvas from any damage during the stretching process.

13. Chain Nose Pliers

Triangular stubby-jawed pliers are commonly used in both jewelry making and wire shaping. Their unique jaw design makes them especially suited for shaping, bending, and crimping wire, which are essential tasks in these crafts.

If you work with beaded jewelry, you’ll find that the tips of these pliers come in handy when you need to open or close jump rings and bead tips. This versatility makes them a practical addition to any jewelry maker’s toolkit.

14. Combination Pliers

Combination pliers are incredibly versatile hand tools, easily recognized by the three distinct sections on their jaws. If you look closely, the very tip of the pliers features a serrated area, which is perfect for gripping onto different objects securely.

Just behind this, you’ll find a round, also serrated section; this part really comes in handy when you’re working with thicker, round materials like pipes or tubes, making it much less of a struggle to hold them steady.

Moving closer to the fulcrum, the innermost part of the jaws functions as a cutting edge. It’s worth noting that, while many people might casually refer to these as lineman’s pliers, there is actually a key difference: combination pliers lack that characteristic rounded center section found in lineman’s pliers. That detail often goes unnoticed, but it’s what sets the two tools apart.

15. Eyelet Pliers

Pliers like these play a crucial role in clothing-related industries, especially in tailoring and shoemaking. They’re used to attach eyelets those little metal rings you’ll often see where drawstrings or laces go in garments.

Adding an eyelet isn’t just about popping it in; each one has a small ring and a longer hub that need to be firmly crimped into place so they stay put.

These days, most eyelet pliers you’ll find are pretty versatile. Many are designed with interchangeable dies, which means you can switch them out depending on whether you need to punch a hole or actually crimp the eyelet itself.

There are still some older or simpler types that just use a crimping surface, or have a wheel in the top jaw loaded with different die tips, but the multi-function models are much more common now.

16. Fencing Pliers.

At first glance, this unique multi-tool stands out because it looks a bit like a hammer with two handles when viewed from above. The fulcrum is cleverly designed with several notches, making it possible to cut wires of varying thicknesses. On the side of the left jaw, there’s a hammering surface that’s handy for driving staples into place.

Meanwhile, the right jaw features a claw that’s perfect for pulling out staples. The jaws themselves are equipped with both a textured gripping area and a rounded hole, offering a secure hold on different objects.

17. Flat Nose Pliers.

Flat Nose Pliers referred to as duckbill pliers. They have flat, tapered jaws, which makes them especially handy for twisting and gripping metal, as well as manipulating wires and leads. Mechanical and electrical professionals tend to reach for these pliers quite a bit.

One thing that makes duckbill pliers so useful is their ability to create sharp bends and right angles in wire. They’re also great when you need to straighten out wires. Depending on the task, you’ll find versions with long or short noses.

18. Grommet Pliers.

Grommet pliers work a lot like eyelet pliers, both in how they look and how they’re used. Their main job is to punch holes in materials think tarps and then secure the grommets in place.

Unlike eyelets, grommets are meant to be much more heavy-duty. That’s why these pliers are a go-to for projects involving tougher materials, where durability matters.

19. Hose Grip Pliers.

Sometimes called grabber pliers, hose grip pliers are a specialized tool made to help you handle small hoses in tight spots. The jaws are shaped to hold onto hoses securely without causing any damage, which is especially important when you’re working with things like fuel lines, heater hoses, or vacuum lines.

All you have to do is grip the hose and give it a twist to remove or install it. They also come in handy for spark plugs, clamps, and all sorts of small components where a regular tool just won’t do the trick.

20. Linesman Pliers

Often referred to as electrician’s pliers—or sometimes as engineer’s pliers when they come without insulated handles—linesman pliers are remarkably versatile tools crafted from sturdy steel.

The history here is a bit interesting: these pliers are actually evolved from what were once called bell pliers, tools that 19th-century bell hangers relied on for cutting and twisting the wires used to connect household bells before the days of electrification.

Structurally, linesman pliers hinge at a pivot, so when you squeeze or open the handles, the jaws follow suit. The jaws themselves are designed with shallow serrations, which give you a solid grip, especially on flat materials like sheet metal—one reason why they’re a staple for sheet-metal workers.

For electricians, these pliers are indispensable when it comes to twisting wires together into that familiar cone-shaped knot, which then gets capped with a wire nut for safety. Right behind the jaws, you’ll spot a pair of side cutters intended specifically for snipping wire. One word of caution: if you’re tempted to cut nails with these, think twice—the cutters will dull in no time.

21. Locking Pliers

Locking pliers are the kind of tool you end up reaching for more often than you’d expect. They’re sometimes known as plier wrenches, lever-wrench pliers, or even by the well-known brand name “Vise-Grips.”

What sets them apart is their double-lever mechanism, which lets you use them as a handheld vise or clamp—one that really locks down on your workpiece.

To operate them, you squeeze the handles just as you would with any pliers. Adjusting the jaw opening is easy: just turn the screw-drive built into one handle.

Once the jaws bite down on your target, a bit more pressure locks them tight. Releasing them is a breeze, too—just flip the release lever in the opposite handle. Thanks to the compound lever action, these pliers can apply an impressive amount of force.

You’ll find locking pliers in a whole range of shapes and sizes. Most commonly, they come with straight, serrated jaws, and you’ll see lengths anywhere from four up to twelve inches.

There are versions with curved jaws, long-nose designs, flat or smooth jaws, and even models that function like C-clamps. Their versatility means you can often use them instead of pipe wrenches, adjustable wrenches, or traditional clamps, depending on the job.

A quick heads-up, though: locking pliers are best reserved for tasks where you don’t need to preserve the surface of what you’re clamping. The serrated teeth can leave permanent marks or even damage nuts, bolt heads, pipes, or fittings—so if you plan on reusing those parts, it’s wise to choose a gentler tool.

22. Nail Puller Pliers

Nail puller pliers resemble tongs in appearance and feature tapered tips. This design allows users to maneuver the pliers beneath the head of a nail and extract it with relative ease.

Some versions are equipped with additional claws positioned on the back of the right jaw, which help to increase leverage and provide extra pulling force.

23. Oil Filter Pliers

Oil filter pliers stand out due to their unusual C-shaped, toothed jaws—one jaw being noticeably longer than the other. These pliers are a staple in automotive repair shops, where their primary function is to grip and remove oil filter casings during maintenance.

24. Piston Ring Pliers

Piston ring pliers come in two main varieties, both specifically designed for working with piston rings inside engines. The first style features jaws with curved tips that enable the user to gently spread and remove piston rings.

The second style is constructed with larger jaws and several braces, providing added support to the ring and helping to minimize the risk of distortion during removal or installation.

25. Push Pin Pliers

Push pin pliers are easily recognized by their wedge-shaped jaw tips, which are ideal for slipping under the caps of plastic anchors’ pins.

By squeezing the handles, the pliers lift and release the push pin, making it possible to safely extract the anchor. These tools are widely used not only in automotive work but also in any field that relies on plastic anchors for fastening.

26. Round Nose Pliers

Often referred to as rosary or jewelry pliers, round nose pliers are easy to recognize thanks to their rounded, slightly tapered jaws.

Unlike bail-making pliers, the jaws of these pliers meet to form a triangular shape, making them especially handy for creating loops in jewelry—rosaries in particular. In some cases, manufacturers add insulated handles so these pliers can safely be used for electrical tasks.

27. Running Pliers

When working with stained glass, running pliers are almost essential. They allow you to make clean, precise breaks along a scored line. What sets them apart is their wide-tipped jaws, which can be adjusted to suit different glass thicknesses. Most also have a center line marked on the jaws, making it easier to align the tool with your score and get that perfect break.

28. Sheet Metal Pliers

Sheet metal pliers stand out because of their wide, rectangular jaws. These are built for bending sheet metal and forming seams, which is why they’re so common in metalworking shops and industries dealing with sheet metal. You’ll often find versions of these pliers with locking mechanisms, tailored specifically for handling metalwork.

29. Split Ring Pliers

Split ring pliers—sometimes called fishing pliers—are a favorite among anglers and anyone who assembles keyrings.

At first glance, they might remind you of stubby chain nose or needle-nose pliers, but the telltale feature is the hooked tip on the lower jaw. This acts as a wedge, easily prying apart coiled rings so you can slide on hooks, lures, or keys without a struggle.

30. Soft Jaw Pliers

Soft jaw pliers are designed with protection in mind. They come with padded jaws to avoid scratching chrome, soft metals, or other delicate surfaces—something you’ll appreciate if you’re working with plumbing fixtures or scuba gear. You’ll find soft jaw versions of many common plier styles, all adapted to keep vulnerable materials looking pristine.

31. Spark Plug Pliers

Spark plug pliers are designed with narrow jaws, which end either in insulated tongs or cylindrical holders. These specialized tips let you securely grip spark plugs by their boot or by the wires, making them particularly handy during automotive repairs.

If you’ve ever had to remove or replace a spark plug, you’ll know just how useful it is to have pliers that can handle the job without damaging sensitive components.

32. Welding Pliers

Welding pliers combine several features into a single tool. Their jaws resemble those found on combination pliers, but their tips are similar to needle-nose pliers.

With welding pliers, you can take on a variety of tasks: removing spatter, gripping wires, cutting, and even doing a bit of light hammering if needed. It’s no surprise that these pliers are a staple in any welding shop—they’re built to stand up to the demands of welding work.

33. Wire Twisting Pliers

Wire twisting pliers are a bit unique compared to other types. They feature short jaws and include a cutting edge located at the fulcrum. Between the handles, you’ll notice a threaded knob and a cylindrical mechanism, which is used for locking the tool in place.

Once you clamp a wire between the jaws and pull the knob back, the pliers spin, twisting the wire automatically. These pliers are especially popular among jewelers and electricians who need to twist wires efficiently and neatly.

All in all, the world of pliers is more varied than most people realize. Whether or not you ever find yourself reaching for one of these specialized tools, it’s always good to know what’s out there—just in case you’re ever faced with a task that calls for something a little more specific than your average set of pliers.

FAQs

What is a plier used for?

Pliers are made in various shapes and sizes and for many uses. Some are used for gripping something round like a pipe or rod, some are used for twisting wires, and others are designed to be used for a combination of tasks, including cutting wire.

What are the two types of pliers?

Types of Pliers

1. Fixed or solid-joint pliers have a rivet attached to the pivot that allows them to open only to a set width.

2. Adjustable or slip-joint pliers offer two or more widths to accommodate a wider range of tasks.

What is a pliers versus wrench?

Wrenches are designed to fit nuts, bolts and other standard fasteners, on the other hand pliers turn, squeeze and rotate irregularly shaped objects of any size.

What are 3 examples of pliers?

Standard Types of Pliers

1. Water-pump Pliers – for Plumbing Applications.

2. Diagonal Pliers – for Cutting Tasks.

3. Locking Pliers – for Hands-free Object Tightening.

4. Crimping Pliers – for Crimping Complex Electric Applications.

5. Wire Strippers – for Cutting or Removing Insulation of Wire.

When not to use pliers?

Pliers are often misused as general-purpose tools. Their use should be limited to operations for which they were designed: gripping and cutting (never for loosening or tightening nuts). Always use wrenches on nuts and bolt heads, never use a pliers. In fact, don’t use pliers when any other tool will do.

What is the most common plier?

Most-Used Types Of Plier

1. Combination Pliers. Combination pliers are one of the preferred multi-use hand tools among mechanics and professionals in other industries.

2. Needle Nose Pliers.

3. Diagonal Cutting Pliers.

4. Tongue and Groove Water Pump Pliers.