A piezometer is a key tool in geotechnical engineering, designed to measure the pore water pressure also called the piezometric level beneath the surface.

Engineers and geologists use piezometers to monitor the pressure within soils, various geological layers, rock or earth fill, and even structural elements like foundations. With the right sensor, these devices can even measure pore water pressure within concrete.

When you think about piezometers, it helps to picture them as the pore pressure equivalent of a thermometer they offer reliable, direct readings of how much water pressure exists in a specific spot below ground.

What’s more, they don’t just provide a single snapshot; with continuous monitoring, piezometers reveal how pore water pressure shifts over time and across different areas, painting a much clearer picture of subsurface conditions.

The information gathered from piezometers is extremely valuable, especially for understanding how water moves through soil or rock. These measurements can help pinpoint where seepage is happening, highlight areas at risk for issues like piping, and even show how effective seepage control measures are.

It’s no surprise, then, that piezometers are among the most widely used instruments in geotechnical monitoring. There’s actually a lot to discover about them from the different types available to the science behind how they work, not to mention their many practical uses.

In the following sections, we’ll take a closer look at all things piezometer, exploring the basics, the varieties, and some real-world examples to help connect the theory to practice.

What is a Piezometer?

A piezometer is essentially a tool designed to gauge fluid pressure within a system. It does this by indicating how high a column of fluid rises against gravity, which gives you the piezometric head at a specific location.

Unlike pitot tubes, which have to be aimed directly into flowing fluid to capture dynamic pressure, piezometers are set up to measure only the static pressure of the fluid they don’t get inserted into the main flow.

Now, if you’ve ever dealt with observation wells, you know they’re helpful for checking the water level in a formation, but they come with a catch: you need to go out and read them manually. Piezometers make life a bit easier.

Many of them are compatible with electronic pressure transducers, allowing you to collect pressure data more efficiently and sometimes even automatically.

Historically, the first piezometers used in geotechnical engineering were simple open wells or standpipes sometimes called Casagrande piezometers that were sunk into an aquifer.

The classic Casagrande setup involves a solid pipe running down to the depth you want to measure, and then a screened or slotted section right where you’re interested in monitoring groundwater pressure.

To keep your measurements reliable, the casing around the well is sealed off—usually with clay, bentonite, or concrete. This prevents surface water from sneaking in and throwing off your groundwater readings.

It’s worth noting that in confined aquifers, the water level you see in a piezometer doesn’t always line up with the actual surface water level especially if there’s a strong vertical flow.

And in the case of an artesian aquifer, the level shown in the piezometer reflects the pressure of the aquifer rather than the true water level.

You don’t need a huge diameter for a piezometer well; most are much narrower than standard production wells. In fact, 5-centimeter standpipes are pretty typical. These piezometers can be installed in sturdy casings and either buried or pushed into the ground right at the spot where you want to measure groundwater pressure.

When it comes to reading the pressure, there are several options: vibrating wire sensors, air pressure transducers, or manometers, all of which convert the measured pressure into an electrical signal.

The real advantage of these modern piezometers is that they can be hooked up to surface connections, letting you use data loggers or portable reading units. This means you can gather data much faster and over longer periods compared to basic piezometers that require manual checks.

Principle of Piezometer

Understanding pore water pressure is essential in soil mechanics, as it forms the foundation for grasping the concept of effective stress.

In essence, effective stress is what really drives changes in soil behavior over time it’s the shift in effective stress that leads to observable changes, not just the total stress on its own.

In fact, whenever there’s a change in total stress, it’s usually the effective stress that’s responsible for the measurable impact, with pore water pressure playing a critical role.

Now, while measuring total stress can be useful (and there are sensors designed specifically for that), it’s just as important if not more so to monitor pore water pressure directly. That’s where piezometers come in. These instruments are the go-to solution for geotechnical engineers who need reliable measurements of pore water pressure in the field.

Regular monitoring of pore pressure isn’t just a box-ticking exercise. It’s crucial for a few reasons. First, it helps with post-construction monitoring, giving engineers a way to track how soil and structures are behaving after everything’s in place.

Second, staying on top of these readings can alert teams to potential hazards that could threaten the stability of foundations or other critical components.

Beyond safety, understanding pore water pressure can also open up opportunities for more efficient and cost-effective construction. With accurate data, engineers can tweak their designs or construction methods to make projects safer and, in some cases, less expensive.

Why is a piezometer used?

A piezometer is a tool commonly used to measure groundwater pressure in environments like dams, pipes, or any kind of conduit especially when there’s excavation, boreholes, or drainage involved. Having a clear understanding of groundwater pressure is crucial for ensuring both the safety and precision of these types of projects.

Why do we rely on piezometers? First and foremost, they help us see how water impacts soil or rock. When water pressure inside the pores of soil or rock (what engineers call pore water pressure) rises, the ground can actually lose a lot of its strength. In extreme cases, this can even mean the soil can no longer support any load, which is a risk nobody wants to take.

Another important use for piezometers is figuring out exactly where the groundwater level is and how it moves. This isn’t just about knowing how deep the water table is it’s also about understanding the way water flows through embankments, dam foundations, or even the body of a dam itself, whether it’s made of soil, rock, or concrete.

Finally, piezometers make it possible to map out the phreatic line the boundary below which the ground is saturated with water. Knowing where this line sits is key when you’re trying to assess the stability of an earth structure.

How does a piezometer work?

Piezometers play a crucial role in monitoring subsurface water pressure, especially in geotechnical and environmental engineering projects.

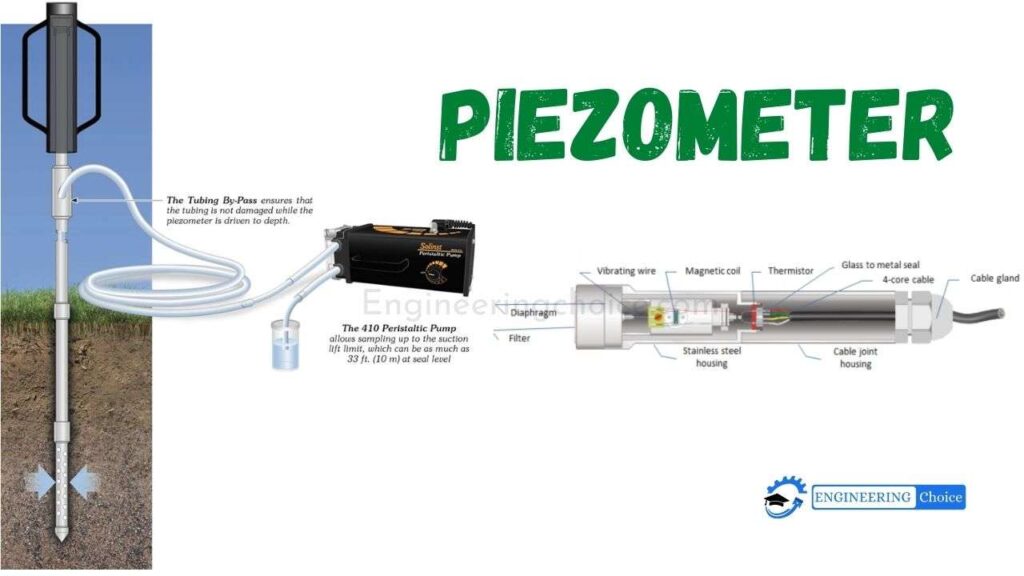

At their core, these instruments rely on a clever bit of physics: water pressure acting beneath the ground is transferred to a diaphragm that’s connected to a tightly stretched steel wire. Any shift in water pressure nudges the diaphragm, which in turn alters the tension in the wire.

Most vibrating wire piezometers are built around a strong, magnetically sensitive wire. One end of this wire is anchored firmly, while the other is linked to the responsive diaphragm often secured to a fixed structure or a calibrated spring.

When pressure beneath the ground rises, the diaphragm bends accordingly, pulling more on the wire and increasing its tension.

What’s neat here is that the tension in the wire mirrors the amount of pressure being applied. So, as pore pressure varies, the change is “translated” into a corresponding change in the wire’s tension. To capture this, the wire is initially tensioned by a coil magnet, and when the system is activated, the wire vibrates at a specific frequency that reflects its tension.

The relationship is described by this formula:

f = {[σg/ρ] ^1/2}/ 2l Hz

Here,

- σ is the tension in the wire,

- g is the gravitational constant,

- ρ is the density of the wire,

- and l is the length of the wire.

As the wire vibrates at its unique frequency, it induces an alternating current in the nearby coil magnet, making it possible to capture and interpret the signal electronically. Interestingly, the pore water pressure is tied to the square of this frequency.

Modern devices like the Encardio-rite Model EDI-51V Readout Logger take care of all the tricky conversions, displaying pore pressure data directly in engineering units for straightforward analysis.

Types of Piezometers

Piezometers generally fall into two broad categories: open piezometers and closed piezometers. Each type comes with its own specific design and functions, which makes them better suited to particular uses or project requirements.

Choosing the right kind of piezometer for any given project isn’t just a technicality it plays a big role in shaping the kind of data you end up with. The type you go for will influence not only how accurate your measurements are, but also how useful and relevant that data will be, especially in the context of the project’s goals and on-the-ground conditions.

#1. Standpipe Piezometers.

Standpipe piezometers, often known as Casagrande piezometers, are among the simplest tools available for monitoring piezometric levels in groundwater studies.

Essentially, these piezometers are just narrow plastic pipes typically around 5 cm in diameter—with a screened or porous section at the bottom. This lower portion is installed in a borehole and packed with sand to ensure proper contact with the groundwater.

To make sure surface water doesn’t skew the results, this porous zone is then sealed off using materials like bentonite, clay, or even concrete. Above the sand, the borehole is usually backfilled with cement mortar or bentonite pellets, finishing off the installation.

The operation is pretty straightforward: groundwater flows into the pipe at the level of the porous section until the water inside the pipe balances with the external piezometric head. This gives you a direct indication of groundwater pressure at that depth.

That said, it’s important not to confuse the reading with the actual water table, especially in unconfined aquifers with significant vertical flow. The piezometer measures pressure at the screened interval, which isn’t always the same as the water table level if there’s a lot going on vertically in the aquifer.

Where these standpipes really shine is in soils that are reasonably permeable they’re a simple, cost-effective, and reliable way to keep tabs on pore water pressures, assuming they’re installed properly. If the pipe diameter is more than 12 mm, you don’t need to worry about air locks the system is self-deairing.

Plus, you can use these pipes for quick permeability checks or to collect groundwater samples for quality analysis.

On the flip side, standpipe piezometers aren’t perfect. They react slowly in low-permeability soils like clay, which means you might be waiting a while for readings to stabilize.

In cold conditions, if water in the pipe reaches ground surface and freezes, you’re out of luck the instrument won’t work until things thaw out. Fine-grained soils can also be an issue, since particles can work their way into the pipe and cause blockages.

Most critically, these open standpipes can’t detect negative pore water pressures (suction), and if the pipe dries out, you’re left without any data. Lastly, while manual readings are simple, automating data collection can get expensive fast.

#2. Vibrating wire piezometer.

Vibrating wire piezometers, often referred to as VWPs, operate on a straightforward yet reliable concept: when the pressure of water within the soil (pore water pressure) changes, it causes a diaphragm inside the device to flex.

This movement then alters the tension on a wire inside the piezometer, which starts to vibrate at a frequency that depends on how much tension there is. The clever bit is that the sensor measures this frequency, and from that, it calculates the actual pressure in the ground.

One of the reasons VWPs are a staple in geotechnical monitoring is their tough construction. Most are built from stainless steel and have ends that are completely sealed off, making them robust enough to withstand harsh environments for years on end.

Manufacturers usually go the extra mile by including features like lightning protection, so you’re not left with a fried sensor after every storm. Plus, there’s often an internal thermistor tucked inside to keep tabs on temperature, which helps prevent those annoying distortions in readings that can happen when it gets hotter or colder outside.

A detail that’s easy to overlook is the filter. Depending on the application, VWPs come with either a sintered steel or ceramic filter these are specifically chosen to stop fine soil particles from making their way into the sensing area and messing things up.

And to deal with the weight of the soil pressing down (overburden pressure), the whole transducer is usually encased in a heavy-duty shell.

One of the practical perks of using VWPs is how quickly they respond to pressure changes. The output is digital, making it straightforward to log data, monitor it remotely, and even get real-time updates if needed. Another neat aspect: they can detect very small negative pore pressures, which is handy for certain types of monitoring.

Something users often appreciate is that the vibrating wire’s frequency output doesn’t get easily scrambled by electrical noise, even when using long cables think distances over two kilometers without much loss in signal quality. It’s this combination of precision, durability, and ease of use that has kept VWPs popular for long-term projects.

That said, VWPs aren’t perfect. One limitation is that once air gets trapped and a positive suction builds up, the device can’t vent that air out. Also, once a VWP is buried and up and running, there’s generally no simple way to double-check that it’s still properly calibrated. This is why, even with built-in safety measures, it’s smart to plan for extra protection where possible.

A couple of other points to keep in mind: VWPs can be sensitive to changes in temperature and barometric pressure though most do compensate for internal temperature swings. And, if you’re installing a push-in style VWP, be aware that the installation process itself can sometimes introduce errors in your readings.

#3. Pneumatic Piezometers.

Pneumatic piezometers provide an indirect method for assessing subsurface water pressure by utilizing compressed gas. The fundamental principle is relatively straightforward: gas is injected into the piezometer tube until its pressure matches the pressure exerted by groundwater in the surrounding soil.

Once this balance point is reached, the equilibrium pressure is measured at the surface, directly corresponding to the pore water pressure beneath the ground.

Installation practices for pneumatic piezometers are versatile. These instruments are typically positioned within boreholes, fill materials, or even larger diameter standpipes, depending on project needs.

Connecting the transducer to a terminal box or a remote readout involves pneumatic tubing, and it’s important to consider how these tubes are routed and protected particularly in areas close to ground surfaces or near zones that will see embankment fills in the future.

Ensuring that hoses are shielded from construction damage is a key step for maintaining the system’s reliability.

As for installation methods, several options are commonly used, such as grout-in, sand-bag, and push-in approaches. Each method has its place depending on site conditions and desired monitoring outcomes.

One notable advantage of the pneumatic piezometer design is that there are no electronics housed at the sensing tip itself. Instead, all pressure measurements are taken at the surface with a gauge.

This separation not only extends the lifespan of the sensor since it’s less prone to electrical failures but also means there’s no need for calibration at depth. Furthermore, these devices function reliably even in freezing ground conditions, which can be a challenge for some other sensor types.

Another practical benefit is that pneumatic piezometers eliminate the influence of surface tension within water, which can improve the accuracy of pressure readings.

In general, they are considered straightforward to install, provide precise point measurements, and can withstand demanding site environments. The response time is typically quick, allowing for timely data collection.

However, there are a few operational considerations. Taking measurements can sometimes be a bit labor-intensive, and the nuances involved mean that someone with relevant expertise may be needed for data interpretation.

Also, maintaining a high standard of cleanliness is critical, as any dirt or contamination can significantly impair performance. Regular use is advised to keep the internal valve operating smoothly.

There are some limitations to keep in mind. For instance, traditional pneumatic piezometers cannot record negative pore water pressures, and they are not designed for simple datalogging. Additionally, operation requires a supply of nitrogen or carbon dioxide gas, both of which must be resistant to corrosion to ensure long-term function.

#4. Titanium piezometer.

Titanium piezometers are a reliable choice for depth testing, especially in situations where durability and corrosion resistance matter. These devices can output signals in the 4-20 mA range, making them straightforward to hook up with standard industrial data loggers something you’ll appreciate if you’ve ever dealt with tricky setups.

You’ll often see titanium piezometers in use where it’s necessary to monitor water levels or pressure, particularly in tough, corrosive environments like saltwater settings.

They’re also valuable for tracking pore-water pressures during sudden events, like earthquakes, or for keeping tabs on water levels during pumping tests. The titanium construction means you don’t have to worry about the device breaking down when conditions get harsh.

#5. Electric Piezometers.

Electric piezometers take a different approach. At their core, these instruments feature a flexible diaphragm paired with a porous filter, with a tiny water-filled space between them.

To pick up pressure changes, the setup relies on either a vibrating wire or a strain gauge both of which track how much the diaphragm bends under pressure. The measurements from these sensors are then carefully converted into pressure readings, as long as everything’s properly calibrated.

The installation process for electric piezometers is pretty much identical to what you’d do with an open standpipe piezometer. Once you position the piezometer inside the borehole, you fill the gap between the porous filter and the borehole wall with a mix of cement and bentonite grout.

As groundwater moves, it finds its way into the reservoir, pushing against the diaphragm. The pressure continues to build until it matches the pore water pressure at the depth of the filter.

If you happen to install one of these devices above the water table, keep in mind that the soil’s pore pressure turns negative meaning water is actually drawn out of the reservoir.

This could fill the instrument with air instead, which isn’t ideal and could cause the piezometer to stop working as intended.

#6. Hydraulic Piezometers.

Hydraulic piezometers are designed with a porous filter and a water reservoir, both of which are connected to a pressure gauge using water-filled tubes. These tubes serve a dual purpose: not only do they facilitate the movement of water for accurate pressure readings, but they also allow any trapped air or gas to be purged from the system.

This prevents air pockets from forming in the reservoir, which could otherwise compromise the reliability of the measurements.

When using a hydraulic piezometer, the total hydraulic pressure is recorded directly, and from this, the actual pore pressure within the soil or rock is calculated. One notable benefit of this system is its ability to be flushed meaning air or gas can be cleared from the tip as needed. This feature is particularly useful, as it helps ensure the data remains both timely and accurate.

In terms of construction, a typical hydraulic piezometer features a ceramic, porous tip that is sealed into the specific zone where measurements are required. Readings are then taken at the surface via a pair of hydraulically filled nylon tubes.

The ceramic filters can be either high air entry (HAE) or low air entry (LAE), depending on site requirements, and the housing itself might be made from materials such as Delrin plastic, brass, or stainless steel.

It’s common to see the twin tubing encased in a polyethylene sheath, with a terminal reading board and de-aerating cylinders included for system maintenance.

These instruments are favored for their simplicity and reliability, offering excellent long-term stability and precision. They’re also responsive, registering changes in pore pressure quickly. The hydraulic design is effective in mitigating the issues caused by air entrapment or gas buildup within the piezometer tip a problem that can cause significant errors if left unaddressed.

Hydraulic piezometers are capable of measuring both positive and negative pore pressures, with typical ranges extending from approximately 2000 kPa down to –50 kPa. Many modern systems feature wireless tips for improved durability and convenience, and materials are selected specifically to withstand corrosion in harsh environments.

These piezometer systems are also valuable when performing constant head permeability tests in the field, and they are especially well-suited for long-term monitoring applications or when very small negative pore pressures need to be measured.

However, for optimal performance, hydraulic piezometers require a high air entry filter and de-aired water, and their effective measurement range is generally limited to situations where the filter tip is at a similar elevation to the pressure measuring device.

It’s worth noting that the hydraulic tubing can be susceptible to damage, particularly in situations where significant settlement occurs, so providing adequate protection is important. Routine maintenance may also include periodic de-aeration, as some air can still find its way into the system over time.

#7. Piezo-Resistive Piezometers

Piezo-resistive piezometers work on a pretty interesting principle: they measure changes in pore water pressure by picking up tiny shifts in electrical resistance within a sensing element—usually a silicon strain gauge.

When the water pressure around the sensor goes up or down, that little piece of silicon flexes ever so slightly. This small physical change tweaks its electrical resistance, and that’s how the device knows what’s happening with the pressure.

But here’s where it gets practical: that change in resistance doesn’t just sit there as raw data. The device translates it into a standard electrical signal, like the well-known 4-20mA output. This makes it really easy to hook up with just about any monitoring system out there.

Many of these piezometers also rely on a Wheatstone bridge circuit, which is a classic way to detect even tiny changes in resistance.

What sets piezo-resistive piezometers apart is their ruggedness. They’re usually built with corrosion-resistant materials and tough components so they can handle harsh field conditions without missing a beat. Inside, they’re fitted with precise pressure transducers and the right kind of filtering, which helps them stay accurate even in tricky installation environments.

If you’re after reliability, these sensors deliver. They’re known for their excellent accuracy and stability, plus they can take high-frequency measurements—meaning they don’t get tripped up when the pressure is changing quickly.

Durability is another big selling point: they’re made to withstand wide-ranging pressures, and most models offer temperature compensation, which is a real plus for field work.

Versatility is another thing to like. Piezo-resistive sensors slot right into most monitoring setups, and they can even handle pressures below atmospheric (so both positive and negative readings are on the table).

That said, while there’s a lot to like, it’s worth mentioning a downside that doesn’t always get discussed: since these are electrical sensors, they have to be properly sealed.

Any moisture that sneaks in can cause electrical connections where you don’t want them, which can mess with the accuracy of the readings. It’s a small thing, but in the field, it matters.

#8. Drive-in/Push-in Piezometers

These devices are particularly suited for installation in soft clays, organic soils, or fine-grained cohesionless soils basically, in conditions where the Standard Penetration Test (SPT) N-value is less than 10.

The installation process is flexible; they can either be pushed straight into the ground or placed within Cone Penetrometer Test (CPT) soundings, and they’re also compatible with drilled boreholes if you’re using conventional drill rods along with specialized adaptors.

When it comes to measuring capabilities, there’s some variety. You can get them with either vibrating wire or strain gauge sensors, depending on what fits your project needs best.

Durability and long-term reliability are strong points here, so you don’t have to worry much about ongoing performance. Another thoughtful detail is the anti-smearing cone (or frame) design, which helps ensure a proper borehole seal right at the top of the piezometer.

Also, most of these come with built-in temperature sensors as a standard feature, making them even more versatile for various monitoring situations.

Difference Between Monitoring Wells and Piezometers

When it comes to tracking groundwater levels, you’ll often hear about two tools: shallow monitoring wells and piezometers. While they might look pretty similar at first glance they’re both essentially pipes installed underground the way they work and the kind of information they provide aren’t quite the same.

Let’s start with shallow monitoring wells. These are pipes with perforations running along their length beneath the ground. Thanks to these openings, water from various points within the groundwater table can flow into the well.

As a result, when you check the water level inside a shallow monitoring well, you’re actually seeing the combined effect of water entering at different depths. This setup lets you monitor the pressure and movement of groundwater along the whole section of the well.

That’s why many professionals prefer monitoring wells when they want a broader picture of groundwater conditions. You might also hear these referred to as observation wells, perforated pipes, or open-sided wells.

Piezometers, on the other hand, work a little differently. Instead of being open along their entire length, a piezometer is typically sealed except for an opening at the very bottom.

This design means that when you measure the water level in a piezometer, you’re getting the pressure or hydraulic head—at a single, specific point at the base of the pipe, rather than an average along a section. Sometimes people call piezometers “cased wells.”

It’s important to understand the distinction between these two tools, because the one you choose really depends on the type of measurement you need.

If you want to observe how groundwater pressure changes at a particular depth, a piezometer is the way to go. If you’re more interested in general water table levels or need information from a wider area, a shallow monitoring well will serve you better.

Piezometer Applications

Piezometers play a crucial role in both engineering and environmental science because of their accuracy and reliability in measuring pressure. These devices aren’t just limited to one or two applications; their versatility means they can be used in a wide variety of projects.

By incorporating piezometers into different types of work, professionals can enhance project safety, boost efficiency, and make more sustainable choices throughout the process.

Dam and Embankment Safety Monitoring

Piezometers play an essential role in ensuring the safety and overall performance of dams and embankments. These instruments are invaluable when it comes to checking how well a dam is functioning, especially by tracking water levels at various points.

In most cases, piezometers are used to keep an eye on how water behaves specifically the flow patterns in different types of dam structures, whether they’re made from earth, rockfill, or concrete, as well as their foundations.

Their use isn’t limited just to dams, though. Whenever there’s any kind of fill involved like in embankments for highways, railways, roads, bridges, or similar projects piezometers provide ongoing monitoring.

What makes piezometers especially useful is the early data they offer about how the soil responds to extra weight. With this information, engineers can take steps to prevent things like hydraulic fracturing or dangerous shifts in slip planes.

In short, piezometers give us the insight needed to anticipate and avoid potentially risky situations in a wide range of construction projects.

Slope Stability Assessment and Landslide Prevention

In regions where landslides are a concern, or on slopes that have been specially engineered, piezometers play a vital role in assessing slope stability.

By keeping an eye on the pore water pressure, engineers can get a clearer picture of how stable a slope actually is whether it’s a natural hillside or a man-made embankment.

This information is key, not just for evaluating the current situation but also for making smart decisions about how to prevent future problems or address any issues that crop up.

Generally, these instruments are deployed specifically in locations already identified as being at risk for landslides or slope failures, rather than being used everywhere indiscriminately.

This targeted approach ensures that monitoring efforts are both efficient and effective, focusing resources where they’re needed most.

Groundwater Resource Management and Aquifer Studies

Piezometers play a crucial role in the sustainable management of groundwater resources. These instruments allow us to accurately monitor groundwater levels, which is essential for maintaining the balance between effective use and long-term preservation of aquifers.

By providing ongoing data, piezometers support strategies aimed at ensuring that aquifers are neither depleted nor neglected, making them invaluable for both water conservation planning and resource management.

What makes piezometers especially valuable is their ability to offer detailed insights into several aspects of groundwater systems. Through regular monitoring, they provide measurements of groundwater levels, the direction and speed of groundwater flow, and help map the structure and volume of aquifers.

Piezometers also help identify where water is entering or leaving an aquifer the recharge and discharge zones which is critical information for managing water supplies responsibly.

Beyond general aquifer monitoring, piezometers are also used in more specialized studies. For instance, they’re helpful in examining how tidal movements or groundwater interactions affect coastal soils. This versatility makes piezometers an indispensable tool in both research and practical management of groundwater.

Construction Project Monitoring

When it comes to major civil engineering projects, keeping tabs on groundwater levels and pore pressures is a crucial step, and that’s where piezometers come in. These instruments are widely used to monitor changes below the surface, especially on sites involving things like tunnels, dams, or deep excavation work.

For engineers on the ground, the data from piezometers isn’t just numbers on a chart it’s essential for assessing lateral earth pressures and double-checking that containment systems are doing their job.

In fact, piezometers play a key role in tracking the stability of various structural elements, whether you’re talking about foundations, embankments, abutments, or large fills.

From the initial site prep all the way through to the final stages of construction, this information helps maintain both safety and efficiency on complex builds.

Environmental Monitoring

Piezometers play a crucial role when it comes to environmental monitoring and protection. They aren’t just limited to tracking groundwater levels; they also give us insight into the quality of the water itself.

For instance, with the help of piezometers, researchers and environmental professionals can keep tabs on potential pollutants—everything from industrial chemicals and pesticides to hydrocarbons, heavy metals, and even radioactive substances.

In real-world scenarios, piezometers become particularly valuable at sites where contamination is a concern, like landfills or areas with a history of industrial activity.

By installing these instruments, we can not only detect whether contaminants have made their way into the groundwater, but also observe how these substances spread over time.

Plus, they provide a practical way to check if waste management systems are actually doing their job or if adjustments are needed.

Dewatering Operations and Permeability Testing

When a construction site needs to be dewatered, piezometers play an essential role in monitoring how water levels shift over time. This helps project teams evaluate how well their dewatering efforts are working and, just as importantly, maintain safe conditions for anyone working in the excavation area.

Beyond basic monitoring, certain types of piezometers like hydraulic piezometers offer even more flexibility on site. For instance, they can be used to perform constant head tests directly in the ground, giving engineers a way to measure hydraulic conductivity right where it matters, rather than relying solely on lab data.

On top of that, open standpipe piezometers can also be helpful tools for estimating how easily water moves through the soil, which is crucial information when dealing with permeability.

Advantages of Piezometer

Piezometers have numerous advantages, leading to their strong position in subsurface investigations:

- Trustworthiness and Precision: Many modern piezometers, especially vibrating wire ones, are field-proven in very dependable and precise measurement; they also show considerable stability over a long time in extreme situations. No piezometer gives you better information about the groundwater and its behavior, which is a precondition to make informed decisions in engineering.

- Increased Quality of Readings and Connectivity: Automated piezometer systems provide continuous readings so that the data set is richer and provides information on daily and seasonal variations, which results in improved understanding of subsurface behaviors across different time spectra as compared to manual methods. It is rare to have continuous piezometric levels since automated systems can do datalogging, and be read remotely, so that you are monitoring piezometric levels in almost real time while reducing field time drastically while improving job efficiency.

- Advanced Measurement Potential: Several modern types of piezometers, e.g., vibrating wire, hydraulic, drive in, can also measure small negative pore pressure (suctions); suctions are critical in partially saturated soils.

- Quality and Eat of Repair if Needed: When piezometers are manufactured, they can be made from heavy, corrodible materials of manufacture, e.g., stainless steel, and they will last long and perform well even in underground settings that may be approaching extreme conditions (use of specialized titanium piezometers is an option in highly corrosive conditions).

- Simple to Use and Adaptable (specific piezometer types): Although very advanced systems are available, open standpipe piezometers are simple and inexpensive and also easy to understand in terms of design. Pneumatic piezometers are known to be simple to install. Piezometers can be used in plenty of different places, and applications, including urban settings, agriculture, and even in industries.

Disadvantages of Piezometer

While piezometers have benefits, they also have limitations and challenges:

- Variable Response Time: The response time of piezometers can greatly vary due to type and soil permeability. Open standpipes can show lengthy response times in low permeability clays and therefore delay data acquisition.

- Measurement Limitations: Traditional piezometers have limits in measuring pressure due to their design. They are generally not appropriate for high pressures, since this could mean unreasonably long glass tubing. Likewise, they can not measure vacuum pressure, as this would allow atmospheric air to enter the tube instead of liquid rising into the tube. Piezometers should not be used to measure the gauge pressure of a gas due to leakage concerns. Simple open standpipes cannot measure negative pressures of pore water.

- Environmental Susceptibility: Certain environmental conditions could affect performance, for example, if the water level of an open standpipe freezes near the ground surface, the standpipe could not be read. Many newer electrical piezometers have internal protection methods; other piezometers would need external lightning protection. Temperature and barometric pressure changes affect reading changes, where advanced models often incorporate temperature compensation.

- Installation Complexities: Installation can be challenging. The “traditional method” of sand and bentonite pellets could create a “technical disaster” where the material created a void in the borehole known as “bridging,” compromising the piezometer. The “fully grouted method” minimizes the risk of bridging, however, drilling precision is necessary and multiple piezometers would need support during the casing removal. New installations, no matter what method, typically need settlement time and usually require nearly a month of settlement before the system establishes equilibrium with the ground conditions, before reliable baseline readings can be made.

- Maintenance and Calibration: Certain piezometer types, such as vibrating wire models, have no viable means of checking the calibration once placed. Hydraulic piezometers need de-aired water and some must be de-aired on a regular timeframe to help not create air accumulation faults. Pneumatic piezometers need a continuous supply of gas to ensure operation.

- Data Interpretation Challenges: Manual reads can take a lot of time and often require a skilled operator to interpret.

- Vulnerability to Damage: Piezometers could be at risk to damage from construction activity. The hydraulic tubing may be damaged where ground movements have been large enough to present risk to the measurement systems.

FAQs

What is a piezometer used for?

Piezometers are the geotechnical sensors that are used to measure pore water pressure (piezometric level) in the ground. It is designed to measure pore water pressure in the soil, earth/rock fills, foundations, and concrete structures.

What is the difference between a manometer and a piezometer?

While a manometer is utilized to measure gas pressure, a piezometer is employed to do the same for liquids. Manometers, which contain mercury and oil, are used to gauge gas pressure, whereas peizometers, which contain mercury and water, are used to gauge liquid height.

What is the difference between a piezometer and a pressure gauge?

A piezometer is an ordinary tube that is vertically connected to a liquid system for which the pressure must be measured. A pressure gauge is used to measure fluid intensity, as well as to set up and tune fluid power machines.

How does a piezometer measure water level?

Piezometer is used to measure underground water pressure. It converts water pressure to a frequency signal via a diaphragm and a tensioned steel wire. A change in pressure on the diaphragm causes a change in tension of the wire.

When can piezometer not be used?

It cannot be used to measure the gauge pressure of a gas i.e. leakage of gas through a piezometer. It cannot measure the vacuum pressure. Instead of a column of liquid going up in the tube, the atmospheric air will enter into the pipe through the glass tube.

How accurate is a piezometer?

High Resolution: VW piezometers provide a resolution of 0.025% FS. High Accuracy: Most ranges provide an accuracy of ±0.1% F.S.

References:

- Piezometers: An essential component to dam safety, accessed June 22, 2025, https://www.nww.usace.army.mil/Media/News-Stories/Article/3482026/piezometers-an-essential-component-to-dam-safety/

- What Is Piezometers? – Aavad Instrument | Manufacturer of RTD …, accessed June 22, 2025, https://www.aavadinstrument.com/what-is-piezometers/

- Ultimate Guide To Piezometer – Meaning, Principle, Usage & More …, accessed June 22, 2025, https://blog.kritsnam.com/ultimate-guide-to-piezometer-meaning-principle-usage-more/

- Piezometers | Complete Guide and InSAR data Integration, accessed June 22, 2025, https://detektia.com/en/piezometers/

- Piezometers and the Projects They’re Used On | SOCOTEC UK, accessed June 22, 2025, https://www.socotec.co.uk/media/blog/piezometers-and-the-projects-theyre-used-on

- Piezometers – Sisgeo, accessed June 22, 2025, https://sisgeo.com/products/piezometers/

- Environmental drilling (piezometer) – Bernier Wells, accessed June 22, 2025, https://www.puitsbernier.ca/en/specialized-drilling/environmental-drilling-piezometer/

- Monitoring 101: Using a Piezometer – Encardio Rite, accessed June 22, 2025, https://www.encardio.com/blog/monitoring-101-using-a-piezometer

- Vibrating Wire Piezometer – RST Instruments Ltd, accessed June 22, 2025, https://rstinstruments.com/product/vibrating-wire-piezometer/

- Standard Vibrating Wire Piezometer User Manual – Soil Instruments, accessed June 22, 2025, https://www.soilinstruments.com/wp-content/uploads/2020/12/Man106-Vibrating-Wire-Piezometer-Standard-MN1114-Rev1.4.1.pdf

- Vibrating Wire Piezometer – Types and Operating Principle …, accessed June 22, 2025, https://www.encardio.com/blog/vibrating-wire-piezometer-types-and-operating-principle/

- Piezometers: role, operation and advice – imaGeau, accessed June 22, 2025, https://www.imageau.com/en/blog/piezometers-role-operation-and-advice/

- Hydraulic Piezometer – Soil Instruments, accessed June 22, 2025, https://www.soilinstruments.com/products/water-monitors-piezometers-meters/hydraulic-piezometer/

- Piezometers – Field Monitoring in geomechanics, accessed June 22, 2025, https://www.field-monitoring.org/piezometers

- Piezometers Application Guide V1.1 | Geosense, accessed June 22, 2025, https://www.geosense.com/wp-content/uploads/2021/05/Piezometers-Application-Guide-V1.1.pdf

- 5 Types of Geotechnical Instrumentation and Their Monitoring Applications – ECS, accessed June 22, 2025, https://www.ecslimited.com/5-types-of-geotechnical-instrumentation-and-their-monitoring-applications/

- Piezo-Resistive Piezometers – Stanlay, accessed June 22, 2025, https://www.stanlay.in/geotechnical-structural-monitoring/piezometers/piezo-resistive-piezometers/

- Piezo-Resistive piezometers – Sisgeo, accessed June 22, 2025, https://sisgeo.com/products/piezometers/piezo-resistive-piezometers/

- Guideline for installation of pneumatic piezometers (PP) – Open Government program, accessed June 22, 2025, https://open.alberta.ca/dataset/d8b4fe4a-2307-4873-b407-3f2a5d5a6511/resource/088bdf9e-0717-4d13-8803-6fead53d8dc3/download/trans-gbmp-pneumatic-piezometer-installation.pdf

- Hydraulic Piezometer System – GeoSystems, accessed June 22, 2025, https://www.geosystems.com.au/pdf/Geosystems/GEOS_1510_Hydro_Piezo.pdf

- Drive-in Piezometers, VWP-3400 & SGP-3500 Series – Geosense, accessed June 22, 2025, https://www.geosense.com/wp-content/uploads/2021/10/Drive-in-Piezometers-V1.0.pdf

- Drive-in piezometers – Sisgeo, accessed June 22, 2025, https://sisgeo.com/products/piezometers/drive-in-piezometers/

- [Solved] If one were to use a piezometer to measure fluid pressure, w – Testbook, accessed June 22, 2025, https://testbook.com/question-answer/if-one-were-to-use-a-piezometer-to-measure-fluid-p–61c2ef4a20525e1cc0a2bead

- [Solved] A Piezometer cannot be used for pressure measurement in pipe – Testbook, accessed June 22, 2025, https://testbook.com/question-answer/a-piezometer-cannot-be-used-for-pressure-measureme–63b5ad43e6025a83fd9c5449