What is Scotch Marine Boiler?

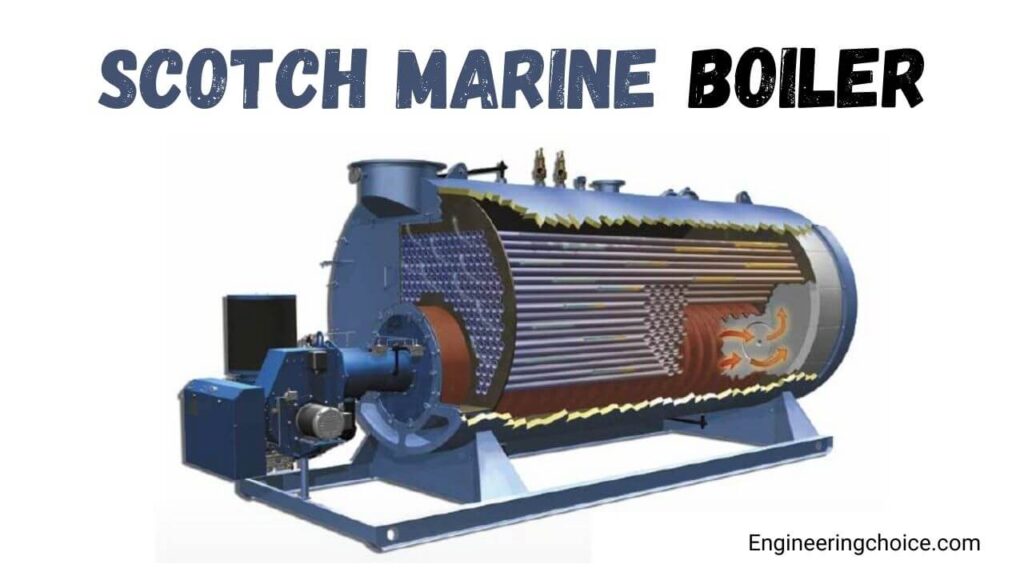

The “Scotch” marine boiler, often simply referred to as the Scotch boiler, is a type of steam boiler primarily recognized for its widespread use aboard ships.

Its design features a compact, horizontally oriented cylindrical shell. Within the lower section of this shell, one or more large cylindrical furnaces are situated. Positioned above these furnaces are numerous small-diameter fire tubes.

The combustion gases and smoke generated in the furnace travel to the rear of the boiler before looping back through the small tubes and exiting via the chimney. These tubes terminate in a smokebox, which is located externally to the boiler shell.

Classified as a fire-tube boiler, the Scotch boiler operates by channeling hot flue gases through tubes immersed in a water tank.

This design traces its origins to the earlier Lancashire boiler. Like the Lancashire, it incorporates multiple separate furnaces to maximize the heating surface area relative to furnace capacity.

However, the Scotch boiler diverges from the Lancashire in two notable ways: first, it employs many small-diameter tubes typically three to four inches (76.2 to 101.6 mm) in diameter to enhance the heating surface area relative to cross-sectional size; second, it effectively reduces the overall length of the boiler by folding the path of the gases back upon itself.

Parts of a Scotch Marine Boiler

The following are important construction parts of Scotch marine boiler:

- Furnace: This is the space located above the grate and below the boiler, specifically designed to burn solid fuel within the boiler system. In a single-ended boiler, there are typically four furnaces used for firing. These furnaces are often corrugated to enhance their structural strength. In this type of boiler, each furnace is equipped with its own dedicated combustion chamber.

- Combustion Chamber: Positioned usually beneath the boiler shell, the combustion chamber serves as the area where fuel combustion takes place, generating steam from the water contained within the shell. It is constructed from several fine plates that remain fixed in place, including the top plate, backplate, two side plates, and the tube plate.

- Smoke Box: The smoke box connects the combustion chamber to the chimney through multiple horizontally arranged smoke tubes. As the smoke travels through these tubes, it is guided toward the chimney for expulsion.

- Chimney: The chimney’s primary function is to release smoke and combustion gases from the boiler into the atmosphere. It acts as a conduit through which the flue gases are safely discharged.

- Boiler Shell: Made from steel plates shaped into a cylindrical form and joined by riveting or welding, the boiler shell must possess sufficient strength to contain both water and steam. It also serves as a protective enclosure for the internal components of the boiler. Additionally, all essential boiler fittings are mounted on the boiler shell.

Construction of Scotch Marine Boiler

This boiler is composed of several fundamental components, much like other boilers. I will provide a detailed overview of each part, and if anything has been overlooked, please feel free to point it out.

To begin with, there is the furnace. Similar to other boilers, the furnace is where fuel combustion occurs inside the boiler. Specifically, a single-ended Scotch marine boiler is equipped with four furnaces. Each of these furnaces contains its own dedicated combustion chamber.

Moving on to the combustion chamber itself: this is the area within the boiler where the fuel is burned. The chamber is constructed with several plates, including the top plate, backplate, two side plates, and a tube plate. Additionally, a series of smoke tubes are arranged horizontally, connecting the combustion chamber to the chimney.

Next is the smokebox. Given that the boiler contains multiple smoke tubes—arranged horizontally and linking the combustion chamber to the chimney—the smokebox serves as the passage through which the combustion gases travel. After the fuel burns, the resulting smoke passes through these tubes before entering the chimney.

Finally, like in most boilers, the chimney functions to expel the burnt gases and smoke generated during operation, releasing them safely into the atmosphere. Another essential part of the boiler is the boiler shell.

Working of Scotch Marine Boiler

Water surrounds the tube in this system. The heat generated inside the tube is quite high, which causes the tube itself to become hot.

As the tubes heat up, they transfer this heat to the surrounding water. This process causes the water to undergo phase changes—first from liquid water to saturated steam, and then from saturated steam to superheated steam.

The operation of the boiler is straightforward. Fuel is introduced and burned in the combustion chamber, which in turn heats the water.

Initially, fuel is fed into the furnace through a fire hole. Once the fuel is inside the furnace, it ignites via the fire hole. The combustion of this fuel takes place within the combustion chamber.

Now, focusing on heat transfer: the heat generated in the combustion chamber is used to warm the water that surrounds it. This follows the fundamental heat transfer process typical of a standard fire tube boiler.

When the water transforms into steam, it is directed to the steam turbine. During fuel combustion, flue gases and smoke are produced, which must be safely released into the environment.

To achieve this, the exhaust gases travel through smoke tubes and eventually exit via the boiler chimney.

The chimney then releases these gases into the atmosphere. In this boiler design, water surrounds the furnace, combustion chamber, and smoke tubes, providing an extensive heating surface area. This arrangement enhances the efficiency of heat transfer during boiler operation.

Types of Scotch Marine Boiler

There are two main types of Scotch Marine Boilers:

- Single Finished Scotch Marine Boiler.

- Double Ended Scotch Marine Boiler.

1. Single Finished Scotch Marine Boiler

This type of boiler features a large-diameter circular shell combined with a relatively short length. Single-end Scotch boilers typically measure up to 3.5 meters in length.

They contain between one and four furnaces, which are accessed from the front end of the boiler. Historically, the Scotch boiler was widely used as a marine boiler on steamships across various countries.

Single-end steam boilers have lengths reaching up to 3.5 meters and accommodate one to four furnaces that enter through the boiler’s front end.

2. Double Ended Scotch Marine Boiler

Older double-ended Scotch Marine boilers commonly featured vertical Galloway tubes within the combustion chamber. These tubes were designed to enhance water circulation inside the boiler, thereby helping to alleviate material stresses.

Such double-ended steam boilers can reach lengths of up to 6.5 meters. In these boilers, furnaces are positioned at both ends, with each end containing between two and four furnaces.

Advantages of Scotch marine boiler

- Compared to other boilers, this model is relatively compact in size.

- It demonstrates a high level of efficiency in its operation.

- This boiler is also economically advantageous due to its cost-effectiveness.

- A significant benefit is its ability to produce steam using any type of water.

Disadvantages of Scotch Marine Boiler

- This type of boiler is suitable only for small or limited-scale plants and is not practical for large industrial setups.

- Being a fire tube boiler, its steam generation efficiency is relatively lower when compared to water tube boilers.

- It requires a comparatively larger floor area to achieve the desired output.

- Managing load variations with this boiler is challenging and cannot be easily controlled.

Application of scotch marine boiler

- It is used at marine works.

- Or we can say it is used on ships.

FAQs

What is a Scotch marine boiler?

A “Scotch” marine boiler (or simply Scotch boiler) is a design of steam boiler best known for its use on ships. The general layout is that of a squat horizontal cylinder. One or more large cylindrical furnaces are in the lower part of the boiler shell. Above this are many small-diameter fire-tubes.

What is the life expectancy of a Scotch marine boiler?

Even though proper boiler room maintenance can ensure your boiler operates reliably to the end or past its life expectancy, your boiler will only last so long. Scotch Marine Boilers, made of steel, can last over 50 years. Cast Iron Sectional Boilers can last between 20 and 30 years.

What is the efficiency of a Scotch marine boiler?

Scotch marine boilers are fire tube boilers that are rated to have a minimum efficiency of 81%.

What are the two types of marine boiler?

Boilers fall into two categories: water-tube and fire-tube ones, according to which substance passes through the tube and which flows round the outside. They are used to provide steam for propulsion or for various ship services.

What is the purpose of a marine boiler?

The steam produced by boiler is used onboard ship for various processes like heating applications – Fuel oil heating, Oil tank heating, Cargo heating, Air Conditioning, Galley supply, generating power, running cargo pump turbine, steam driven deck machinery and Fire Fighting, etc.

What temperature should a marine boiler be?

Large auxiliary boilers used for marine purposes are usually top-fired ‘D’-type boilers. D-type water-tube boilers by Babcock & Wilcox can be designed for a steam capacity of 10,000 to 300,000 lbs/hr, pressures from 250 to 1,250 psig, and a maximum temperature of 850F (for gas fired units).