What is Underwater Welding?

Underwater welding is also referred to as hyperbaric welding, which is a form of welding done at high pressures.

It can be done in the water (wet welding) or in a dry environment, usually in a pressurized enclosure (dry welding) with even steel being welded.

Wet welding means much different conditions than dry welding!

We use a term hyperbaric welding when using a dry method and underwater welding in a wet environment. The uses for hyperbaric welding are many, most often for repair jobs on ships, offshore oil platforms, and pipelines. Steel is the most often welded metal.

Dry welding is chosen over wet underwater welding when there are high-quality welds to be completed; there is far better control over the conditions that can be achieved, for example prior and post-weld heat treatments.

Thus, having better control also leads directly to better process performance and ultimately, a substantially higher quality weld compared to a wet weld. So when high-quality welds are needed, dry hyperbaric welding is usually utilized.

Research into dry hyperbaric welding at depths of 1,000 meters (3,300 ft) is ongoing. In general, just the inherent challenges of assessing the integrity of underwater welds (feasible using various nondestructive tests!), but particularly difficult with wet underwater welds because it is substantially more difficult to locate defects (if they exist) beneath the surface of the weld.

There are two methods to weld underwater: wet welding and dry welding.

Wet Welding

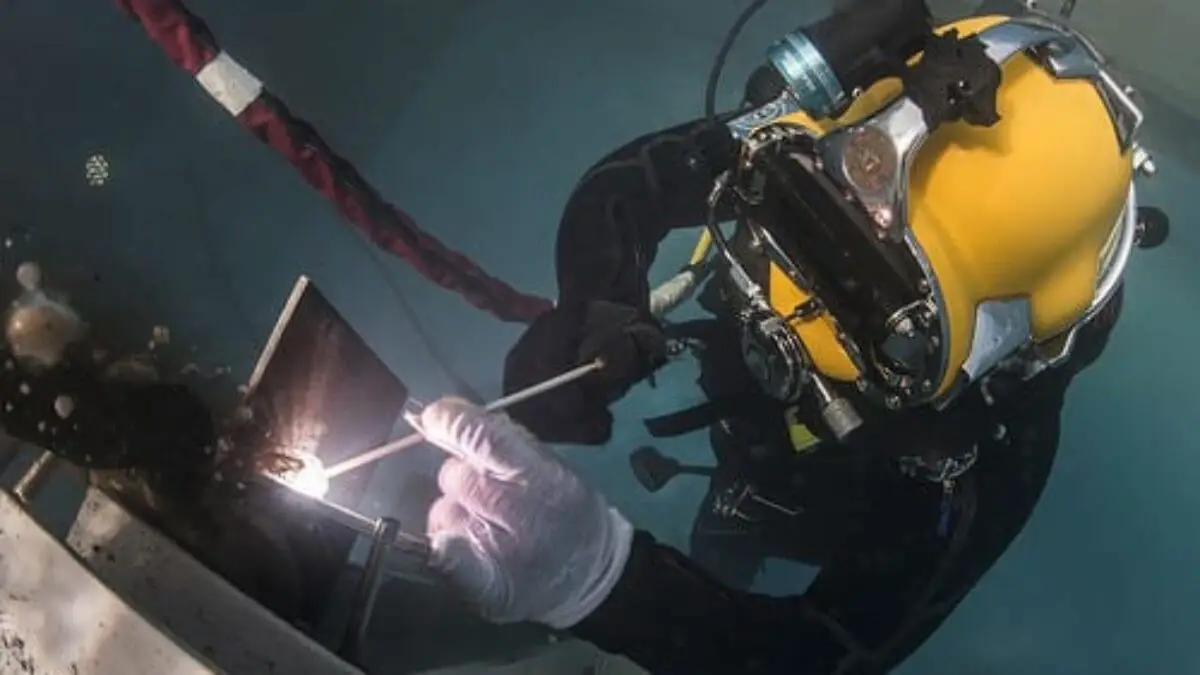

Wet welding entails the diver performing the weld directly in the water. It involves using a specially designed welding rod and employs a similar process used in ordinary welding.

Here are the advantages to wet welding:

- Cheap and fast

- High tensile strength

- Ease of access to weld spot

- No habitat

- No construction

Dry Welding/Hyperbaric Welding

Another technique for underwater welding is hyperbaric welding or dry welding. Hyperbaric welding is when a chamber is sealed around the item that needs welded.

The chamber is then filled with gas (usually a gas mixture of helium and oxygen, or argon), which in turn pushes the water outside the hyperbaric sphere. This means that the welding can be performed in a dry environment.

Here are some advantages of dry welding:

- Welder/diver safety

- Higher weld quality

- Surface monitoring

- Non-destructive testing

How Does Underwater Welding Work?

It is equally surprising how many different ways welder divers perform underwater welding. After being assigned a project, project managers and qualified welder divers explore and decide among the multitude of underwater welding types that could meet their requirements. Read below to learn more about their particular welding processes.

1. Wet Welding

Generally, divers use Shielded Metal Arc Welding (SMAW) or “stick welding” since it is the most economical and versatile option for wet welding.

In wet welding, an electrical arc is created between the electrodes and the structure metals (e.g., steel, stainless steel and aluminum) to be welded together.

It is critical for welder-divers to keep the electrodes clean; and, when they arrive at the weld area, the divers typically look around the swimming area to ensure that there are no obstructions or dangers in the immediate area before performing the weld.

When the diver is ready, he or she lays the electrode on the surface of the weld; and, signals to their dive team to flip on the current, producing 300-400 amps of electricity using direct current (DC).

Regarding how the diver does not get electrocuted, it is related to the flux (or coating) on the electrode, which produces a thick layer of gas bubbles over the weld to cover the welding process, preventing the electricity from mixing with the water, corrosive gases, and oxidizing materials.

Additionally, the team uses direct current (DC) because it is safe and more economical to use underwater than alternating current (AC).

Below are some other common wet underwater welding methods:

- Flux-cored Arc Welding (FCAW) – Utilizes a filler metal or electrode that is supplied continuously in order to weld, for example, nickel-based alloys, and cast-iron metals.

- Friction Welding (FW) – Uses large amounts of friction and heat in a process that does not melt the material but fuses metals, or thermoplastics.

2. Dry Welding

As we mentioned before, dry welding or habitat welding is the same welding process, where welding occurs in a hyperbaric chamber.

After the area which needs welding has been sealed, the water is flushed out with peri-licensed-air and replaced with a mixture of gases such as helium and oxygen.

Once all the water has been removed, the hyperbaric chamber will then be pressurized to the appropriate depth to avoid decompression sickness.

Ultimately, the technique used will depend on the size of the chamber. Let’s take a look at the four types of dry welding methods from which the welder-divers can choose:

- Pressure Welding: Refers to working in a pressure vessel that has an approximate one atmosphere unit of pressure (similar to pressure at sea level).

- Habitat Welding: The welder diver enters the chamber, which is similar to a room and is filled with the same pressure outside it, (ambient pressure) at working depth. The chamber will displace the water into the surrounding water before the welder diver enters.

- Dry Chamber Welding: The welder diver will enter from underneath and be covered only from the head down to the shoulders. (with diving equipment)

- Dry Spot Welding: This is the term used for chambers that are clear and basically the size of a person’s head. The clear chamber is placed on the weld site and the welder diver will have to insert the electrode into the habitat that will conveniently seal around it.

Dry underwater welding utilizes Shielded Metal Arc Welding (SMAW) and Flux-cored Arc Welding (FCAW) with the following common welds:

- Gas Tungsten Arc Welding (GTAW): Known as “TIG” welding, the process uses non-consumable tungsten electrodes, which is heat, along with an electric arc to weld stainless steel, aluminum, and other metals requiring welding.

- Gas Metal Arc Welding (GMAW): TIG is known for it’s multiple metal transfer methods i.e. GMAW, also known as MIG welding, uses shielding gas that runs through the welding gun around the electrode to weld non-ferrous metals like alluminum.

- Plasma Arc Welding (PAW): PAW also uses an electric arc but rather than a large arc that is generalized, PAW can conform the arc to its need which allows for high arc (plasma) speed, intense heat to weld stainless steel, aluminum, and other metals.

In regards to expansive deep underwater welds inside a large hyperbaric chamber, welder divers typically work in pairs.

After the operators place the chamber in position in the water and fill the chamber with gas, the welders descend to the same depth (in a diving bell), swim into the hyperbaric chamber, and begin welding, typically alternating between 6-hour and 8-hour shifts.

How Much is an Underwater Welding Salary?

Underwater welding is easy to learn but takes years to master. Most underwater welders begin their careers in diving school and are eager to get in the water even after the training is completed.

Based on statistics gathered from commercial divers across the world, the average annual underwater welders’ salary is $53,990 or $25.96 per hour (Knapp, J., et al., 2019). However, the vast majority of salaries fall within the range of $25,000 – $80,000.

The best paid diver welders in the heavily populated top $83,730 while the least paid diver welders in the low population areas make around $30,700.

Diving experience and the type of location you work in are the two greatest factors that weigh in on the underwater welders salary.

Some commercial divers make an underwater welding salary upwards of $300,000+ per year.

Why the large pay range?

Most underwater welders are paid either by the hour or per project, meaning that Joe Diver may earn a whopping $30,000 in a few months of a major contract.

He may then spend the next five months trying to find his next contract.

Here are the main factors that impact your underwater welder salary:

- Experience

- Certification

- Environment

- Depth of Work

- Dive Methods

- Underwater Welding Equipment

- Distance Offshore

- Overtime

- Other Factors

Every factor is part of a larger equation for increased pay, marketability, and career opportunity.

But to be passionate about this career, you need to know where it will take you.

1. Inland Income

In your regions pond, river, and lake areas, you’d expect to take home a check for about $40,000 – $80,000. Most of your work will be along slip ways, bridge, dam, and pond and lake work as well.

Inland welder divers are not paid quite what their offshore diver counterparts are.

However they enjoy a lighter workload (40 hour weeks) and less travelling. Sadly when it comes to welding, freshwater is a more dynamic environment being that it is lacking in salt ions.

You should expect to get lots of practice before igniting your arc here.

2. Offshore Income

In ocean environments, you could be looking at $40,000 – $100,000 or higher each season.

Offshore underwater welders spend the bulk of their time on oil rigs or large ocean-going vessels like Navy ships. Their schedules are exceedingly demanding; it is not uncommon to see undersea welders working 80 hours or more in a week.

Since undersea welders often make 28-day trips, and then are back to shore in 2 – 3 weeks (laying equipment), they often work when they do go offshore.

While offshore underwater welders might be involved in cleaning, pipe welding, and pipe installation beneath large platforms offshore, they should have a decent head on their shoulders to repair large machinery.

If they are also trained as a Diver Medical Technician, that’s an added bonus.

Another difference between inland divers and offshore welder divers is that those who dive offshore must come back in for the winter months. The oceans can be dangerous; tidal waves, hurricanes, etc.

If you plan ahead, you can find seasonal work at a welding shop along the coast and gain even more welding experience until spring rolls around.

The Money Tide

Underwater welders take big strides in their earning potential, both inland and offshore, after 3 – 5 years in the industry.

Those early formative years make you or break you! If you make it through you will become the big fish: your chances for employment will be much better than the minnows (your less experienced peers).

FAQs

How much do underwater welders actually make?

Their pay is influenced by the harsh working conditions, specialized skills required, and high risks involved. Most underwater welders in the United States make between $25,000 to $80,000 per year. However, highly experienced offshore underwater welders can make well over $100,000 annually.

Do underwater welders make $100 an hour?

For beginners, the pay can range from $20 to $30 per hour, while experienced professionals typically earn an average of $40 to $60 per hour. For specialized and demanding assignments like deep-sea welding or working in remote and challenging locations, hourly rates may surpass $100.

What is the process of underwater welding?

Underwater welding, commonly referred to as hyperbaric welding, involves welding under intense pressure. There is wet water welding, that takes place inside the water or dry welding that takes place in a dry, pressurised enclosure and steel is the most common metal used material used to weld.

Is underwater welding a good career?

The most experienced, most respected underwater welders can make between $200,000 and $300,000 per year. The more they work, the more they grow, and the more they earn for themselves.

What is the life expectancy of an underwater welder?

Understanding Underwater Welding Life Expectancy. The life expectancy for underwater welders typically ranges from 50 to 60 years. This relatively lower life expectancy is attributed to the physically demanding nature of the job, which places a considerable strain on the body over time.

What’s the highest paid welding job?

Here are the current top 5 highest-paying welding jobs.

1. Rig Welder. Annual Salary: $52,000 – $207,000.

2. Underwater Welder. Annual Salary: $38,000 – $147,000.

3. Nuclear Welder. Annual Salary: $22,000 – $143,500.

4. Industrial Pipeline Welder. Annual Salary: $23,500 – $133,500.

5. Military Support Welders. Annual Salary: $37,000 – $160,000.