Nylon is one of the most recognizable polymers, specifically plastic, in the manufacturing context. The family of nylons is composed of thermoplastics and serves many functions with a wide range of utility as they can be made into fibers, films, and molded shapes.

There are many types of nylon and we will discuss five of them here in order to provide some insight into how they are manufactured and subsequently used.

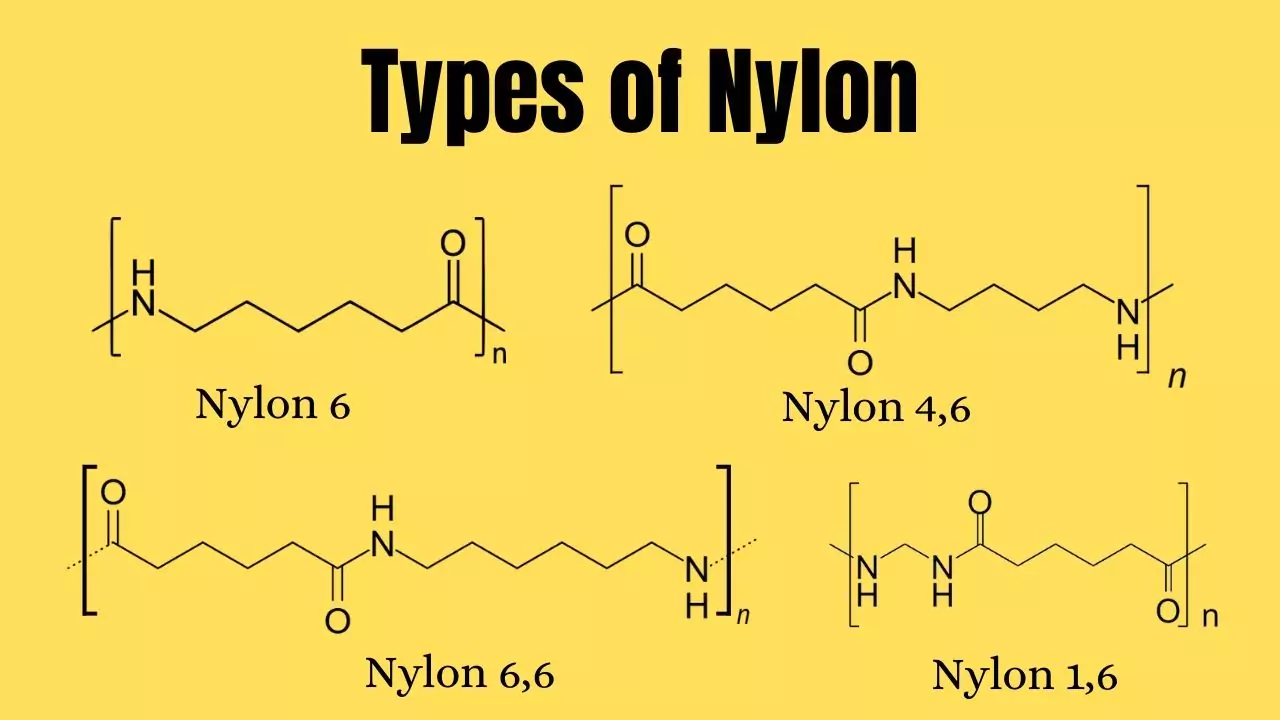

Types of Nylon

1. Nylon 1,6

While this is not a standard for fabrics, it is a top option for moisture absorption! This is a combination made using three substances: adiponitrile, formaldehyde, and water. Then it is created through a reaction called acid catalysis.

2. Nylon 4,6

This version was created specifically with the goal of producing a nylon able to withstand much higher temperatures than standard grades of nylon.

Because of this benefit, it’s usually applied in engine-related components (like transmissions), brakes, and cooling systems because they are less prone to melting compared to other grades of nylon.

3. Nylon 510

You will note that 510 is classified with 6,6 (which we will cover) as it is comprised of pentamethylene diamine and sebacic acid.

It is much more expensive to produce, so you won’t see 510 made in bulk. However, small batch production will be produced for the scientific and industrial fields, where it is known for its strength and usability.

4. Nylon 6

If you want something that is stretchable and strong, and that exhibits a nice sheen, no. 6 should be your best bet—it also holds and absorbs decent amounts of water.

It is a dyed readily, and can withstand heat up to 150 ℃ before turning into a molten pool. It is a popular choice across a variety of industries, getting blended into construction materials, medical and electronic products, and into materials used in the clothing industry.

5. Nylon 6,6

Also known as polyamide 66 (or PA 66), this nylon is specifically developed to give manufacturers a bit more temperature-resistance and a lot less moisture-absorbency.

The nylon’s yield strength and toughness are higher than most nylon grades, making it a solid candidate for wear pads, slide bearings and materials which will be in contact with oils and chemicals.

How Nylon Is Made

Once you have reacted adipic and diamine acids, nylon (which has different formulas depending on the type you are using) is then extruded from an extruder and forced through multiple small holes into usable fibers.

These fibers are wound onto bobbins and the process is the same as any industrial-scale process. Thus, the fibers are wound onto spools or cones and then woven into materials, textiles, and garments.

Generally, during these processes, nylon is dyed in different colors based on function and aesthetics, and blended with different textiles before it is ultimately produced.

Quality

Various types of nylon will be analyzed according to many different traits and standardized procedures which will help you determine if it is good or bad quality nylon.

However, Some traits might be perceived as bad in certain scenarios (in the case of moisture absorption) could be perceived as positive benefits in another situation or application.

The outcome all depends on what physical, chemical, and mechanical properties are desired for the intended use, and then one can select which nylon can provide the qualities needed for that application.

Cost

Considered in relation to many other comparable materials, you find that nylon is relatively cheap. In fact, when nylon was first developed, it was more expensive than silk.

But these days, not only is it cheap, it becomes even more cost-efficient when blended with other materials, to the point where, regardless of nylon from this list or other types of nylon, every type of nylon can be used in a manufacturing environment. So not only is nylon relatively very cheap, it is reliable and versatile.

Environmental Impact

Nylon is technically infinitely recyclable, but it is, in fact, a plastic. It is one class of material that is eventually broken down to microplastics, which are found everywhere from the oceans to the air we breathe.

This material and its production and recycling processes all produce greenhouse gases. Even though it is a useful material with many favorable properties, this still doesn’t make it environmentally friendly.