Ultimate tensile strength refers to the highest level of stress a material can endure before it finally breaks. To determine this property, we typically use a tensile testing machine, which gradually pulls on a sample until it fractures.

Throughout the process, we pay close attention to how much the material stretches and the force being applied, as these measurements reveal important material properties.

Calculating the ultimate tensile strength is straightforward: you simply take the force needed to break the specimen and divide it by its initial cross-sectional area.

In this article, I’ll walk you through what ultimate tensile strength means, how it’s measured and calculated, and provide a few practical examples along the way.

What Is Ultimate Tensile Strength?

Ultimate tensile strength refers to the highest stress a material can endure before it breaks. When a load is applied, the material initially responds by deforming elastically, meaning it will return to its original shape once the load is removed.

As the load increases, the material begins to deform plastically, and these changes become permanent. Eventually, if the load continues to rise, the material reaches its ultimate tensile strength, the maximum stress it can handle.

Beyond this point, the material fails and separates into two or more pieces. In essence, ultimate tensile strength offers a clear indication of how much force a material can resist before it gives way.

What Is the Other Term for Ultimate Tensile Strength?

The ultimate tensile strength, often abbreviated as UTS or sometimes simply referred to as tensile strength or TS, represents the maximum stress a material can endure before it breaks. These terms are interchangeable and all describe the same characteristic: the greatest tensile stress a material withstands just before complete failure.

How Does Ultimate Tensile Strength Work?

To determine a material’s ultimate tensile strength, it is essential to know both the applied force and the cross-sectional area. The calculation itself is straightforward: stress or strength is found by dividing the force by the area. In mathematical terms, this is expressed as:

Stress or Strength = Force / Area

The distinction lies in how these terms are used. Stress refers to the force per unit area at any given point during loading, while ultimate tensile strength specifically describes the highest stress the material can endure before it breaks. Essentially, ultimate tensile strength marks the limit of what the material can handle without failing.

What Is the Significance of Ultimate Tensile Stress in Materials?

Tensile strength plays a crucial role in assessing how well a material can handle stress before it ultimately breaks. For example, when selecting materials for suspension bridges or safety harnesses, it is essential that these materials can endure considerable forces without giving way.

Knowing the ultimate tensile stress of a material helps engineers and designers make informed choices, ensuring that the selected material will perform reliably within the intended application.

What Is the Formula for Calculating the Ultimate Tensile Strength?

The formula for calculating ultimate tensile strength is:

Ultimate Tensile Strength = Force / Area

In this context, the “force” refers to the maximum load that the material can withstand before it breaks, while the “area” denotes the original cross-sectional area of the specimen prior to any deformation.

It’s worth noting that the equation for ultimate tensile stress is essentially the same as that for tensile strength. The distinction lies in their emphasis: stress measures the force applied per unit area, whereas strength specifically refers to the force needed to fracture the sample, considered per unit area.

How To Calculate Ultimate Tensile Strength?

To determine the ultimate tensile strength of a material, a standard tensile test is conducted. The process begins with shaping the specimen into what is commonly referred to as a “dumbbell” or “dogbone” form; this geometry encourages the sample to fracture at its narrowest section, allowing for accurate measurement.

The next step involves measuring and noting the cross-sectional area of the specimen. With these preparations complete, the sample is placed into the tensile testing machine. The machine then applies an increasing load until the specimen eventually breaks.

Most contemporary tensile testing devices not only track the applied force but also calculate and display the tensile strength automatically, using the recorded cross-sectional area.

In cases where this function is not available, tensile strength can still be determined manually by dividing the maximum force recorded by the original cross-sectional area, as shown in the equation:

Strength = Force / Area

What Is the Unit for Ultimate Tensile Strength?

Tensile strength is measured as force applied over a specific area. In the imperial system, this is typically reported as pounds per square inch (PSI). The metric system, on the other hand, uses newtons per square meter, which is more commonly referred to as a Pascal (Pa).

While the terms might differ, they represent the same unit. For materials like metals and polymers, where tensile strength values can be quite large, measurements are often given in megapascals (MPa) instead.

What Are Examples of the Ultimate Tensile Stress of Different Metals?

A range of metals that are commonly tensile tested are listed below:

1. Steel

Steel is essentially an alloy made up mostly of iron, with carbon content usually kept below 2%. The addition of carbon is what gives steel its increased strength and hardness compared to pure iron. Depending on the specific composition and how the steel is processed, its tensile strength can fall anywhere between 200 and 2000 MPa.

Because of this combination of durability and versatility, steel has become one of the world’s most widely used metals, especially in structural roles—from civil engineering projects to the framework and essential parts of vehicles.

2. Aluminum

Aluminum stands out as one of the most widely used metals, largely because of its impressive strength-to-weight ratio and affordability. These qualities make it a go-to material in various aeronautical and aerospace fields. Depending on the specific alloy, aluminum’s strength can range from approximately 90 to 400 MPa.

3. Brass

Brass is an alloy composed primarily of copper and zinc. Known for its high conductivity and notable malleability, brass can be formed into intricate shapes without difficulty. These characteristics contribute to its widespread use in both plumbing and electrical systems. In terms of mechanical properties, brass typically exhibits a tensile strength ranging from 200 to 550 MPa.

4. Titanium

Titanium is a naturally occurring metal known for its distinctive silver appearance. One of its most notable properties is its exceptionally high strength-to-weight ratio, the highest among all metals.

However, the processing of titanium presents significant challenges due to its hardness, which contributes to its relatively high cost.

Another important characteristic of titanium is its biocompatibility, a factor that underpins its widespread use in medical devices and implants, as well as in the aeronautical industry. The tensile strength of titanium varies considerably with grade, ranging from 275 MPa up to 1100 MPa.

What Are the Factors That May Affect the Ultimate Tensile Stress of a Material?

One of the major factors affecting the tensile strength of a material is the temperature of the material during testing. However, there are several more factors that affect the tensile strength:

- Microstructure

- Composition of material

- Testing conditions (including measurement accuracy and strain rate)

Does the Size and Shape of a Material Specimen Affect Ultimate Tensile Stress?

No, the ultimate tensile stress of a material remains largely unaffected by the size and shape of the test specimen, provided that standardized testing procedures are observed.

This is because the calculation of tensile strength is based on the cross-sectional area of the sample, effectively accounting for any size differences.

As a result, variations in specimen dimensions do not influence the final measurement. Similarly, by factoring in the cross-section, the calculation neutralizes any potential impact that the shape of the sample might have on the test results.

How Does Ultimate Tensile Stress Differ From Tensile Strength?

Tensile stress refers to the amount of force applied per unit area of a material at any moment. When we talk about strength in this context, we’re looking at the maximum point—the threshold where the force per unit area becomes so great that the material ultimately gives way and breaks.

While both tensile stress and tensile strength use the same basic calculation (force divided by area), the key difference is that tensile strength pinpoints the upper limit, just before failure occurs.

How Does the Stress-Strain Curve Relate to Ultimate Tensile Strength?

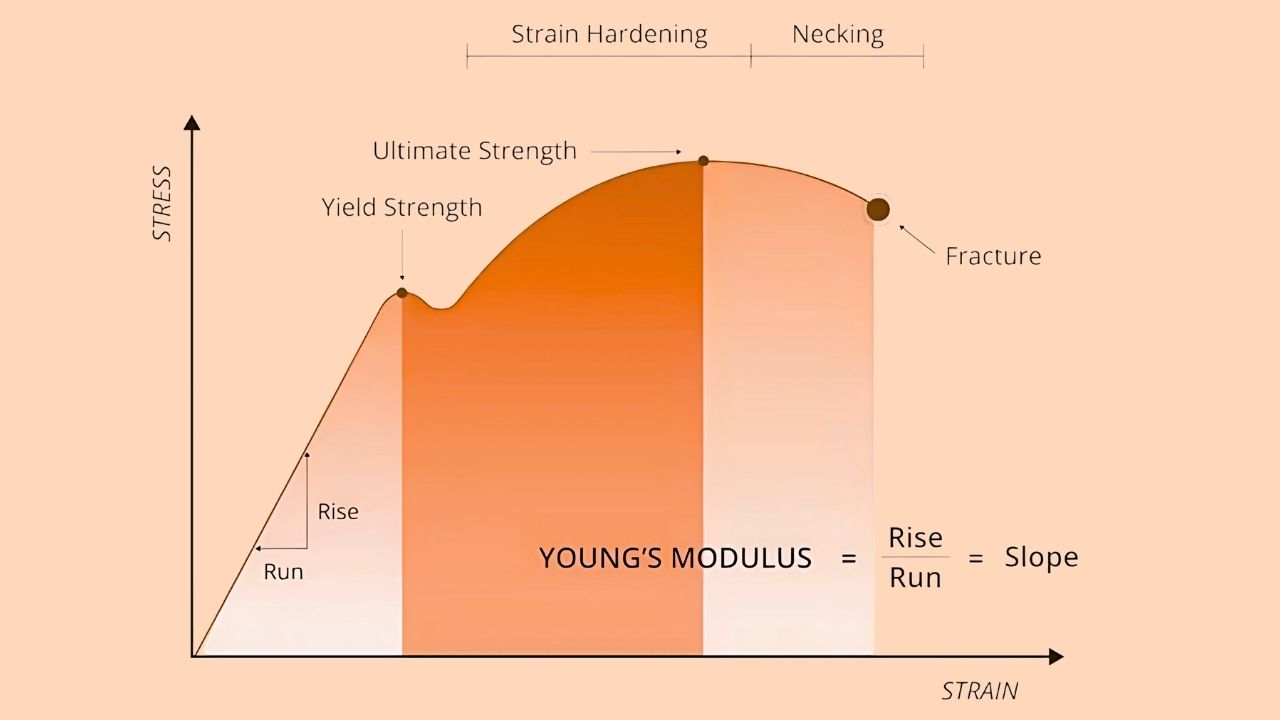

The stress-strain curve illustrates how a material responds to increasing force during a tensile test, mapping the relationship between applied stress and the resulting deformation.

When analyzing this curve, the ultimate tensile strength is identified at the point where the curve peaks and then begins to drop. This drop signals that the material has reached its maximum capacity to withstand stress, which you can observe in Figure 1: Ultimate tensile strength stress-strain curve.

This decline in stress marks the onset of what’s known as “necking.” At this stage, although the force continues to be applied, the material’s cross-sectional area starts to shrink noticeably. This reduction in area is the main reason for the drop in stress, as the material can no longer sustain the same load over a smaller and smaller section.

How Does Ultimate Tensile Stress Relate to 3D Printing?

When it comes to 3D printing, ultimate tensile stress becomes a much more prominent factor than it is in many traditional manufacturing methods. This is mainly because 3D-printed materials tend to show a wider range of tensile strengths.

The main reason for this variability is the way 3D printers build objects layer by layer, which introduces anisotropy, especially with certain printing techniques. On top of that, choices like infill percentage and wall thickness also play a significant role in determining the final tensile strength of a printed part.

How May the Ultimate Tensile Strength of 3D Printed Items Be Optimized for Particular Uses?

When it comes to improving the ultimate tensile strength of 3D-printed materials, one of the most important aspects to pay attention to is the z-direction. This direction runs perpendicular to the layers laid down during printing, and it’s typically where these materials are most vulnerable.

Because the bonds between layers aren’t as strong as those within each layer, applying stress in the z-direction can quickly reveal a part’s weaknesses.

That’s why, whenever possible, it’s best to avoid putting loads along this axis. Beyond orientation, several other choices play a role in the final strength of a printed part—things like which material you use, whether you add fiber reinforcement, your infill percentage, and even the thickness of the walls.

If you can align your part so that, in use, the stresses mostly run parallel to the print layers (and not perpendicular), you’ll usually end up with a much stronger result.

What Part Does Material Choice Play in a 3D Printed Object’s Ultimate Tensile Strength?

The selection of material has a significant impact on the tensile strength of a finished component. While the majority of parts are still fabricated using various polymers, PLA remains a popular option due to its low cost and moderate strength.

That said, PLA falls short when it comes to most load-bearing applications. In situations where greater strength is required, materials such as polycarbonate, ULTEM 9085, or PEEK are often preferred, as they offer substantially higher performance.

Is a 3D Printed Object Stronger if the Ultimate Tensile Strength Value Is Higher?

When two 3D printed components share the same print orientation and structural design, the part exhibiting a higher ultimate tensile stress is generally considered stronger. However, if we compare a 3D-printed item to one produced through conventional manufacturing methods—using the same material—the printed version tends to have lower strength than its traditionally made counterpart.

Does the Printing Speed Impact the Ultimate Tensile Strength of a 3D Printed Part?

Increasing the print speed during 3D printing often leads to a decrease in the strength of the printed part. This happens because, at higher speeds, the print head may not allow enough time for the polymer to become fully plasticized. As a result, imperfections can form within the material, and the adhesion between layers may be compromised.

Can a 3D Printed Parts Ultimate Tensile Strength Be Predicted Before It Is Printed?

It is possible to estimate the ultimate tensile stress of a 3D-printed component before actually producing it, but the reliability of these predictions depends on both the printing method and the tools used. For instance, Finite Element Analysis (FEA) software offers a way to model not only the stresses within a part, but also a range of other material properties.

FEA tends to be most accurate when applied to 3D printing techniques that yield fully dense, isotropic parts metal components produced through powder bed fusion are a good example. When it comes to FDM or FFF printed plastics, however, the predictive accuracy of FEA is noticeably lower.

Even with these prediction tools, actual physical testing remains necessary. Quality control is another significant concern, since 3D printers typically don’t offer the same level of repeatability as more traditional manufacturing processes.