What Is Digital Twin Technology?

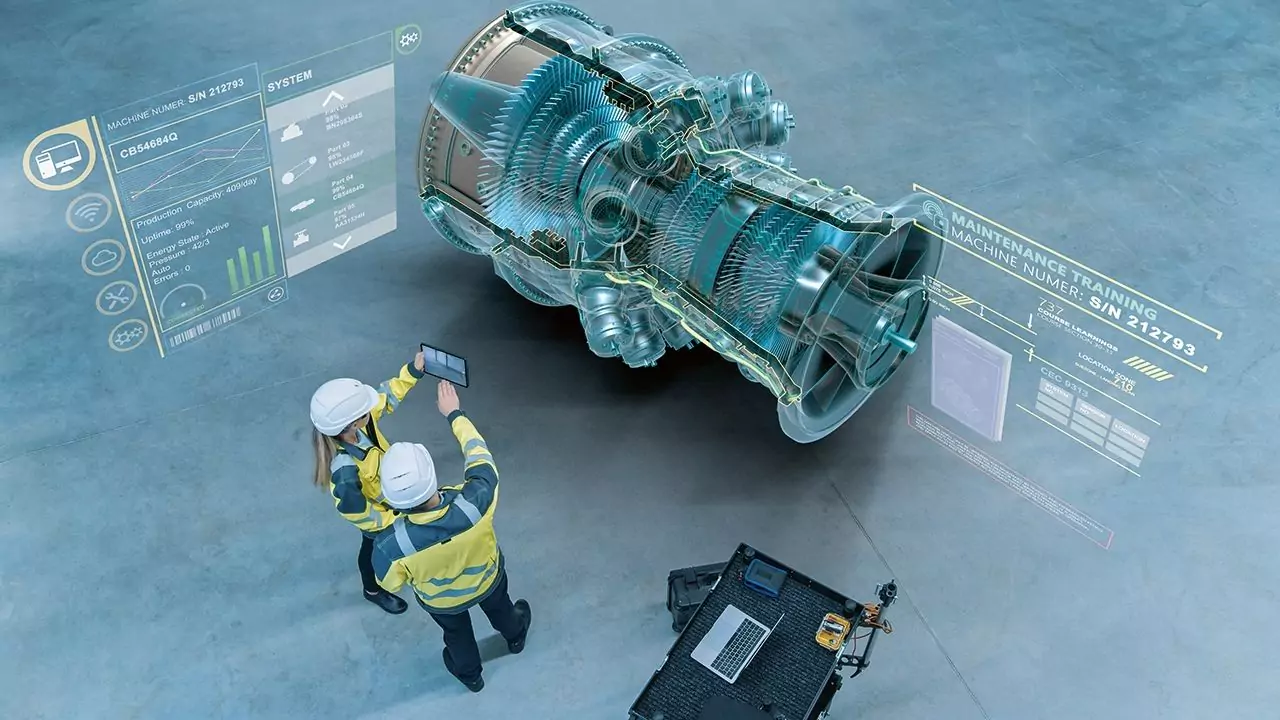

A Digital Twin is an evolving virtual duplicate or replica of a physical asset, system, or process reflecting real-time data through data from real-world sensors.

Digital Twinning simulates and tests physical systems across their lifecycle, from design and prototyping to operation and neat, and enables prediction and optimization in a safe, digital world.

Digital twins, in its earliest forms has emerged from the first kinds of NASA simulations, and, as a notion, took shape in the 2010s. Digital twins can be categorized in a variety of ways, but commonly fall into three categories today:

- Digital Twin Prototype (DTP), at which point virtual representation exists in the design phase,

- Digital Twin Instance (DTI), in which you are making a digital twin of an individual deployed asset, and

- Digital Twin Aggregate (DTA), which comes from aggregating fleets to gain insights.

Why Industry 4.0 Depends on Digital Twins

A Key Component of the Smart Factory Vision

Industry 4.0 is characterized by the interconnectedness of cyber-physical systems integrating the IoT, AI, big data, and cloud/edge computing. Digital twins represent the fundamental technology for enabling smart factories by linking physical machines with digital intelligence.

Real-time Monitoring & Predictive Maintenance

Digital twins integrate disparate data streams coming from temperature, pressure, and vibration sensors to impart timely visibility, detect anomalies, and forecasts failures of equipment that enables predictive maintenance practices. Digital twins will ultimately save costs and downtime with machines while extending their lifespan.

Simulation & Optimizing Prior to Investment

Digital twins can allow users to simulate scenarios referred to as “what-if” studies, thus optimizing layouts, workflows, or machine parameters before trials on real machines need to take place. The result is a quicker time-to-market and less wasted time/resources.

Driving Innovation and Agility in Business

By offering the possibility for continuous simulation and analysis, organizations can graft to traditional virtual-prototyping workflows that allows them to iterate product and process designs at a faster rate, while driving innovation, responding to the market, and enabling new data-driven business models.

Lifecycle Management and Feedback Loops

The capability of a digital twin is not limited to its point of sale and turning over the plant. Digital twins can persist into the operational life of the product and even beyond to decommissioning, thus providing insights informing the next generation of products and maintaining a closed-social lifecycle strategy.

Latest Trends & Real-World Adoption

- Organization-wide Adoption: Organizations like DXC Technology are expanding digital twins beyond manufacturing since they are modeling infrastructure, such as roads, in order to better formalize traffic patterns for sustainability planning.

- R&D Partnerships: Digital twins simulations presented by SAS at SAS Innovate 2025 was possible because the modeling was done in partnership with Epic Games. Digital twins were used as complex models of manufacturing.

- Government and Industry Investment: United States government officials and Siemens executives who spoke at a forum of the Washington Post, remarked that digital twins are vital for reshoring advanced manufacturing, along with enhancing national competitive advantage.

Benefits & Strategic Value

Key Advantages

| Benefit | Description |

| Efficiency & Cost Savings | Optimize processes, cut waste, reduce downtime. |

| Decision-Focused Insights | Data-driven analysis enables smarter strategy. |

| Improved Product Design | Virtual prototyping improves quality and speed. |

| Innovation Acceleration | Simulate and test new ideas safely and rapidly. |

| Sustainability | Optimize resource use and lifecycle planning. |

Deployment Challenges

- High upfront investment costs for sensors, data platforms, and integration.

- Data privacy and cybersecurity risks when modeling real-world systems and/or sensitive systems.

- Challenges in interoperability: planning for the integration of legacy systems into the digital twin ecosystem.

Outlook: Toward Industry 5.0 and Beyond

While Industry 5.0 is still coming into its own, Companies are already seeing capabilities of digital twins supporting more sustainable, human-centered, and inclusive technologies.

According to some recent literature review studies, as digital twins evolve (Industry 4.0 enables Industry 5.0) the new generation of digital twins will provide support for circular economy objectives and human-machine collaboration (Saha et al., 2022).

Looking forward, the coalescence of AI/ML, 5G, edge computing, and even blockchain will begin to harness the next generation of digital twins towards autonomous, smart decision-making systems that can impact industries ranging from manufacturing to healthcare, smart cities, logistics and many more.

Conclusion

Digital twin technology has emerged from being a tool of futurists to being an essential foundation of Industry 4.0.

When technologies of real-time monitoring, predictive maintenance, virtual or otherwise simulated environments, innovative technologies and ongoing innovation where integrated and operationalized, digital twins become a tool to become an engine of business optimization across the full lifecycle of assets.

With the next industrial transformation, intelligent digital twin representations of the physical world will play a key role in the catalysts for sustainable, agile, and human-centered industries, and innovate the innovation leadership role they will exploit for modern innovation.