What is Hinge?

A hinge is a mechanical device which is intended to join two bodies, permitting movement about an isolated axis and restraining movement in the other typical two directions of motion.

A hinge may be thought of conceptually as a type of journal bearing having one degree of freedom allowing for rotation of a shaft in a hole. Hinges allow for motion primarily in one direction which we typically refer to as yaw but can also allow for pitch or roll.

Usually a flexible and jointed object, hinges are mechanical bearings that attach moving parts at various points, thus allowing movement between relative motion between the two connected objects. Movement is limited to a single angle which restricts the motion to a plane.

Hinges are usually flexible and articulated objects which are mechanical bearings that couple moving parts on which the coupling is located at varying distance points.

Since the hinges allow for movement, it allows for relative motion between the two objects connected. The ensuing motion is limited to a single angle which promotes constraint on the motioni n a planar system.

Types of Hinges

When choosing the proper hinges for your project it is important to understand the options available with respect to the different varieties of hinges that exist associated with residential, commercial and industrial applications.

Door hinges, cabinet hinges and industrial hinges are manufactured for distinct installation requirements, momentum requirements for weight, and environmental conditions.

For private use furniture, barrel hinges or concealed hinges can be used because of their minimal look and the fact that they are installed out of sight. Functional or decorative styles (butterfly or strap hinges) combine some aesthetic reinforcement with function, as they are also reliable.

A good fit would be for entry doors, shed doors, barn doors or wooden gates. Heavy-duty options (friction hinges, geared continuous hinges) provide a reliable close lock option for things like electrical enclosures, or any other industrial hardware.

For custom installations, custom hinges can be manufactured to suit specific requirements for various projects. Custom options should be considered on the combined preferences of strength, looks, and durable reputation.

Below is a complete list of the most used types of hinges related to specific applications to help with your selection.

Having knowledge of these hinges will help ensure the successful installation of hinges and ensure performance that requires no regular maintenance for doors, cabinets, gates, commercial applications, and everything in between.

#1. Ball-bearing Hinges

Unlike the more traditional journal-bearing or knuckle-and-pin type of hinge, ball bearing hinges use ball bearings to reduce friction.

Ball bearings help to reduce wear, as they minimize the contact area between the opposing moving surface, and help to provide a very strong support structure in both the radial and axial directions.

Ball-bearing hinges are often chosen for high volume commercial doors and heavy outside doors because they provide the best long-term, smooth operation, with the most durability.

#2. Block Hinges

Block hinges are commonly heavy-duty hinges, either welded or bolted, to parts. Block hinges are some type of hinge for which the barrel is made of galvanized steel and square in shape and size. Industrial-grade block hinges have a stainless steel pin for extra corrosion resistance.

Block hinges are designed for security doors, heavy warehouse gates, etc. They are typically used for high-weight applications, where safety and strength are important.

#3. Bullet or Barrel Hinges

Barrel hinges, often referred to as bullet hinges, consist of two barrels that are fastened into the two connected items (with a low-friction bushing) by welding. Barrel hinges (bullet hinges) do not have leaves like conventional hinges.

Barrel hinges, because they are mounted by welding, are a good choice for narrow frames, gates, and enclosures which require compact, anti-tampering hinge.

Barrel hinges also have a clean profile and additional strength, and can be used in many situations. One common use of barrel hinges is on metal doors and metal door security enclosures.

#4. Butt Hinges

A butt hinge (more commonly termed mortise hinge) is the favored type of hinge for doors, windows, and gates. The butt hinge consists of two leaves connected by a pin or shaft.

One leaf attaches to the movable element (the door), while the other leaf is attached to the stable frame (the door jamb). With the door or window closed, all that is visible is the pin between the leaves, so the appearance is seamless.

Butt hinges can be used on both interior and exterior doors. However, interior butt hinges are typically made from steel for cabinets and less heavy doors; exterior butt hinges can be made using stainless steel or brass to handle rust and corrosion and to handle heavier loads.

Butt hinges are generally 6 inches or smaller and they are installed flush; therefore, the reason they are referred to as mortise hinges.

Full mortise butt hinges leaves are flush with the door and jamb; half mortise does not recess one of the leaves. Some modern butt hinges have adjustable tension, are fire rated, or self-closing in a manner recognized in commercial standard.

#5. Butterfly Hinges

Butterfly hinges are a decorative form of butt hinge that are shaped like a wing and ornate, hench are seen as more decorative.

They are generally used in cabinets, jewelry boxes, and decorative furniture, and help bring a traditional or vintage look where high strength is not important askertgically but decoration and enhanced visual appeal are more important.

#6. Case Hinges

Case hinges are similar to butterfly hinges but have been created for the lighter-duty and smaller scale of application. You will find them on briefcases, suitcases, instrument cases, and trunk lids.

They are low profile and are ideally suited to portable storage and protective enclosures that will be opened and closed frequently.

#7. Concealed Hinges

Concealed hinges- illustrate (Euro hinges, cup hinges or hidden cabinet hinges) are designed for designer furniture, custom cabinetry and kitchens.

These hinges include a hinge cup and hinged arm. When closed, the hinge is completely hidden, which allows for better access to a smooth surface.

Today’s concealed hinges offer three way adjustability (up/down, in/out, left/right), providing flexibility of the cabinet/door alignment.

Most concealed hinge styles include soft-closing or self-closing options. Soft closing hinge have become very popular due to it’s convenience (causing no sounds while closing) and also some styles are available for frameless cabinets and some are made for face frame cabinets.

Concealed hinges are number one option for high-end cabinetry, custom closet, and designer furniture for the detail of the clean appearance as well as flexible functionality.

#8. Continuous Hinges or Piano Hinges

Continuous hinges, also called piano hinges, are long, narrow hinges running the full length of the door, lid, or panel. A continuous hinge provides alignment and support of weight along the length of the hinge.

Continuous hinges are usually used for piano lids, storage chests, access panels, and industrial enclosures. A continuous hinge is available in stainless steel, brass, and aluminum for both interior and exterior applications where high cycle life is needed, as they offer a reliable option for swinging doors.

Continuous hinges are the best option for large doors, fold-down workbenches, and toolboxes, providing better strength and support with less sag under burdened use and fatigue.

#9. Constant Torque Hinges

Constant torque hinges – also known as torque hinges or resistance hinges – provide resistance from the very start until the end of the hinge’s range of motion, allowing for an adjustable workload at all degrees of motion.

Constant torque hinges must be capable of holding a door, panel, or display at any angle by means of pre-set torque specifications. Constant torque hinges are generally utilized in electronics, adjustable monitor mounts, access panels or flaps.

Constant torque hinges are high cycle durable and provide ergonomic control of objects being frequently repositioned.

#10. Flag Hinges

Flag hinges, also known as lift-off hinges or removable hinges are made of two interacting leaves (the Male and Female), with a pinned leaf permanently attached flag hinges are primarily distinguished by their specific advantage of easy disassembly.

This feature allows a door to be removed quickly and easily without tools or disengagement of a latch. They are often used on electrical panels, machine guards, enclosure doors, and modular equipment because they offer a balance of security and serviceability.

#11. Floating Hinges

Floating hinges are uniquely capable of providing rotational movement and limited translational movement so a component (for example, a door or panel) can move away from its article of attachment.

Floating hinges can be utilized for access covers, machine guards, or refrigerator doors when more clearance is necessary for items to open or slightly slide during operation.

#12. Flush Hinges

Flush hinges are constructed so their leaves fit flush across from each other when the door or panel is closed and also eliminate the need for a mortise or recess. Most commonly a flush hinge will be used for small cabinets, lightweight doors or display cases.

Flush hinges are generally used for their sleek aesthetic and straightforward installation. Flush hinges are primarily offered in steel or brass and for light to medium-duty applications.

#13. Friction Hinges

Friction hinges or torque hinges function like butt hinges but provide internal friction within the barrel to hold their position.

The internal friction provides additional resistive force to hold doors, laptop screens, or device covers in an open position and at a predetermined angle without external support.

Friction hinges provide controlled motion at a specific angle without sag or looseness. When used in forensic applications (e.g. electronics, medical devices, laptops, and display equipment) they are essential for stability of motion and performance of electronic devices.

#14. Geared Continuous Hinges

Geared continuous hinges (or aluminum continuous geared hinges) differ from typical butt hinges because they use intermeshing round gear teeth and a continuous vertical cap, thus eliminating knuckles and pins, so the hinge is capable of the following motion.

This provides a benefit when joining heavy commercial doors (aluminum frame doors are increasingly common in schools, hospitals, and heavily used public buildings) because it has better functionality, low maintenance, and better security than other hinge types, but it provides limited movement.

#15. H-Hinges

H-hinges are so named because the short length of the knuckles and pin relative to the leaves makes them appear “H” shaped. H-hinges are mortise hinges and are used on shutters, closet doors, and interior doors where limits on protrusion and low profile are desired.

#16. HL-Hinges

HL-hinges are similar to H-hinges, only one leaf is formed into an “L,” which can provide some added support to heavier doors, gates and access panels.

The L-shaped design aids in distributing weight more efficiently, yet still looks traditional, and, therefore, is often specified for restoration and heritage woodworking applications.

#17. Heavy Duty Hinges

There are many heavy-duty hinges with different configurations, but all are made of greater material thickness and have reinforced structures.

Heavy-duty hinges are made for high-weight doors but can also be used on gates, covers to machines, and access panels in extreme use environments.

Heavy-duty hinges come in mortised, surface-mount, and weld-on types and are made in stainless steel, carbon steel, or in specialty alloys greater resistance to corrosion, weather, and tampering and are necessary in commercial and industrial hardware.

#18. Institutional Hinges

Institutional hinges are constructed with an additional offset from the hinge pin that allows one leaf of the hinge to cover the frame for narrow frames and tight clearances.

These type of hinges are often installed in school, universities, public buildings and in many other places where a full 270° of swing is required to allow full clearance when full opening is required or for the sake of ADA compliance.

#19. Lift-off, Loose Joint, or Slip Joint Hinges

Lift-off hinges, also known as slip joint hinges, or loose joint hinges, are removable types of hinges that consist of a male and female leaf, with a permanent pin on the male leaf side.

Swap male and female, and this would be disastrous for the function of this type of hinge. The leaves can be manufactured to match the pin, which allows for easy removal of doors, panels, or covers for maintenance or use in quick changeovers.

They are commonly used on electrical enclosures, access panels, removable machine guards, and doors that need to be removed regularly.

#20. Living Hinges

Living hinges differ from conventional hinges in that they incorporate integrated flex points fabricated directly into plastic parts with no individual knuckles or pins.

They allow for endless repeated bend and flex and are used in packaging, flip-top caps, and storage boxes.

Polyethylene and polypropylene are the most common thermoplastics used as living hinges to give good fatigue resistance and flexibility and excellent chemical resistance make them cost effective, corrosion-resistant options for disposable or mass-produced products.

#21. Offset Hinges

Offset hinges are modified butt hinges that have a design which increases the width of the doorway, thus increasing accessibility when a wheelchair or larger item passes through the intended opening.

An offset hinge will move a 90° opening door that is 2 inches or more in distance away from the frame onto an exterior wall. Offsetting a hinge provides added clearance without the need for extensive renovations.

An affordable alternative upgraded accessibility is offered in things like accessible bathrooms, medical facilities, or aging-in-place renovations which needs to increase the width of a passage for the wheelchair or larger item to pass through.

#22. verlay Hinges

Overlay hinges are a type of hinge that are most often found in cabinetry where the door will overlay or cover part of the cabinet frame. Depending on the overlay configuration of the hinge full overlay, half overlay or inset overlay hinges will allow for many designs of cabinet doors.

Overlay hinges are most commonly used for frameless cabinets in modern kitchens and offices where aligned gaps and clean appearance are preferred.

#23. Pivot Hinges

Pivot hinges place the axis of rotation at the top and bottom of the door, which provides a new axis of motion, typically yielding 360° of possible rotation.

Pivot hinges are excellent for physically conditioned commercial spaces or any place where a unique opening/closing orientation is desirable to enhance stability, or where hidden hardware is required for architectural doors.

Examples are found commonly in hotel entries or revolving doors and have two axes of travel doors for bi-directional travel.

#24. Quick Release Hinges

Quick release or fastener hinges provide a fast-connect and disconnect feature via a spring-loaded or mechanically actuated pin.

They are widely used for industrial applications such as NEMA enclosures, JIC enclosures, server racks and industrial machinery, where the end-user needs to frequently, and without tools, remove access panels or doors to perform maintenance with minimum downtime.

#25. Self-closing Hinges

A self-closing hinge is outfitted with springs that offer the pull to self-close a door, cabinet, or gate. Many self-closing hinges also use dampers or adjustable tension mechanisms, either mechanical or hydraulic, to offer slower, smoother, more controlled closure, and to reduce noise.

Self-closing hinges are particularly important on fire doors, security gates, commercial kitchen doors, restrooms, and any other area where automatic closure is important for safety, privacy, or policy adherence.

#26. Spring-loaded Hinges

Spring-loaded hinges utilize an internal spring to assist or control the opening and closing action of a door.

There are several variants of spring-loaded hinges, including the self-closing type which automatically closes, or double action spring hinges (also referred to as café door hinges) which allow the doors to swing in both the inward and outward position and return to the neutral closed position.

It is very important to select for a spring hinge rated for your application—weather-tight, weatherproof, or corrosion-resistant if applicable—as outdoor use hinges will make a door last longer while functioning properly during the variable conditions.

#27. Spring Release Hinges

A spring release hinge works much like a quick release hinge but is designed to use a spring-loaded pin that is secured in place with either a knurled knob or a lever.

When the knob or lever is released, the pin can be removed, allowing door or panel removal without any tools. Spring release hinges are also very effective in applications requiring prompt access for repair, inspection, or cleaning.

#28. Stop Hinges

In contrast to other hinge families, stop hinges serve a specific function: to limit rotation beyond a pre-determined angle in a controlled manner, usually by an angle less than or equal to 90°.

The stop hinge is very efficient for controlling the swing of lids, access panels, and safety covers. The stop hinge style can be manufactured as butt, strap, weld-on, and continuous hinge profile.

#29. Strap Hinges or Tee Hinges

Strap hinges (including tee hinges) have long, wide leaves that help distribute weight across a wider range, making them very effective when used on gates, sheds, garage doors, and barn doors.

Strap hinges can be found in both decorative and utility forms, but they tend to be favoured more for rustic, cottage, or farm-style doors. Strap hinges can be used for surface mounting applications and can be installed or retrofitted very easily.

#30. Weld-on Hinges

Weld-on hinges have all-metal construction, which allows them to be permanently secured to a metal gate, a security enclosure, a safe, or a machine through the process of welding.

This provides tamper-resistant security and high load-bearing capability. Because of their rugged construction, weld-on hinges can be found in industrial, automotive, and security applications.

#31. Cane-bolt Latches

The cane-bolt latch is primarily a type of bolt anchor, however, it can also act as a hinge where necessary for temporary or dual purpose applications. A cane-bolt latch is designed to secure doors or gates to a fixed, locked position.

A cane-bolt latch uses several barrels to incorporate a drop rod that drops downward or drops directly into a hole, and is mainly for security. It is very similar to a bolt, but a cane-bolt latch is preferred in agricultural, utility, or warehouse applications where security and access are required.

#32. Damper Hinges

Damper hinges, which are used in slow-closing toilet lids, overhead cabinets, electronic enclosures, and specialty furniture, incorporate a damping mechanism that limits the speed and smoothness of closure, preventing slamming and extending the life of the components.

#33. Lift Assist Hinges

These spring-assisted hinges provide lift support for heavier doors, lids, or flaps. This support allows the user to easily open heavy openings and reduces the strain put onto the user.

These types of hinges are useful tools in totes, trunk lids, and access panels of common building structures that must be lifted frequently. They improve safety for the user by providing had and shoulders ergonomic assistance.

#34. Detent Hinges

Detent hinges are designed to secure a component such as a cover, display, or door at a fixed position (open or closed) without any additional hardware.

This controlled motion, or controlled location, is perfect detent hinges for flip phones, electronic devices, medical equipment, and laptop stands.

#35. Gravity Hinges

Gravity hinge devices utilize the weight of the mounted object as a constant force either to self-close or to self-open doors; the most common examples are bathroom stall doors, saloon doors, and some commercial-style swing gates. These devices make things easier for the user and allow facilities to be self-managed.

#36. Pivot Hinges

Doors with pivot hinges, swing differently than typical doors—the hinge pins are located at the top and bottom of the door, allowing for the possibility of outward and, in some cases, 360 degrees of rotation.

Pivot doors are a modern, interesting version of the more traditional revolving door and cafe door. These types of architectural innovations are preferred in areas that want unique aesthetics, but still want access through the doorway.

#37. Drop Hinges

Drop hinges, also referred to as lift-off hinges, are meant to be used in downward-swinging applications: flap for TV racks, food service counters, and utility drawers.

When opened they lay completely flush so that the workspace is maximized, or the owner can keep the opened surface leveled with adjacent elements.

#38. Clean Room Hinges

Clean room hinges are special hinges for laboratories, medical facilities, or any hygiene-sensitive facility.

These types of hinges use brushes or plastic bushings between knuckles to prevent dust and contaminants from getting into the hinge, accumulating, or marring the ability to clean the hinge and meet cleanliness standards.

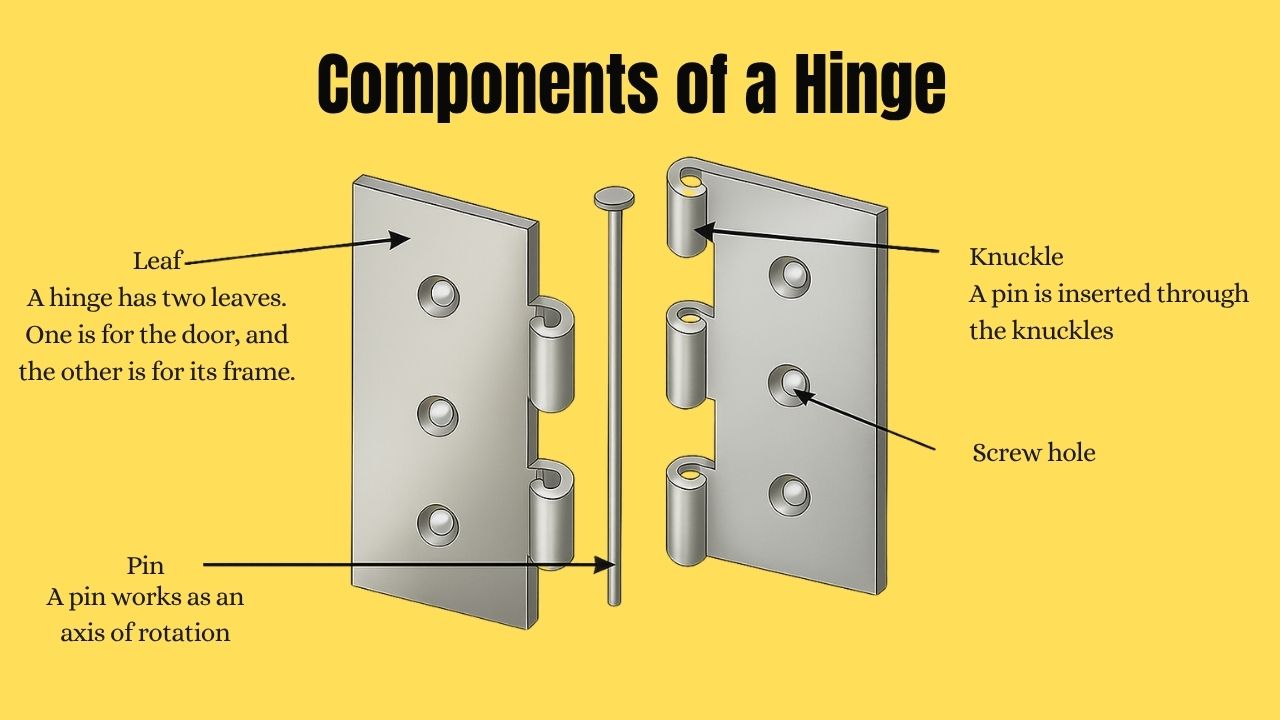

Components of a Hinge

In this section we will define the important terms, such as leaves, barrels, and pins, related to hinge design and hinge hardware. We will develop definitions for these hinge parts and components. We will also include some essential hinge characteristics.

Having this knowledge is valuable to anyone involved with doors, cabinets, gates and industrial settings where hinges will be specified, selected or manufactured or bought.

It does not matter if you are a builder, an engineer or a renovator, you will have access to specification details when choosing related to hinge types or hinge materials and how to select them for durability, security and in relation to how they function.

Hinge Components

1. Leaf

A leaf is a flat plate that projects outwards from the knuckle or barrel hinge. It may be mounted to the fixed or moving body, (such as a door, cabinet, or frame) and may be attached in various ways i.e. screwing, welding or gluing, with one leaf typically secured to the stationary object and the other leaf attached to the moving object that rotates about the pin.

Properly designed hinge leaves are made to structure a larger door weight and resist everyday wear and tear, so it is critical to ensure correct selection during installation of door hinges and cabinet hinges.

2. Knuckle or Barrel

The knuckle, sometimes referred to as the barrel, is the hollow tube-shaped section that attaches to the leaf and is also the section which the hinge pin goes through.

The knuckle is a mechanical part but it acts as a bearing in function – it allows for rotation and it supports the axis of rotation. The number and orientation of knuckles may or may not be the same for a hinge type, and this is typically an indicator of load restrictions and ease of movement.

3. Pin

Hinge pins are a solid shaft or bar that extends through the knuckles, holding the leaves together to enable movement. Hinge pins can be removable or fixed, depending on the security needs, and the installation.

The style of hinge pin, i.e. loose pin, non-removable pin, will assist in determining what type of secure hinge, commonly, will present for commercial and residential application.

As depicted in the image above, the flat surfaces of the hinge are referred to as the leaves. Each leaf attaches to one of the objects being attached, such as one of the leaves attaches to the door, while the other leaf attaches to the frame.

Only the knuckles, or barrels, intermesh with aligned holes that allow for screws or bolts to secure the hinge assembly. The pin holds the knuckles together while connecting the leaves to allow for the classic pivoting action allowed in a hinge.

Hinge usually creates genuinely a revolute joint that permits smooth rotations along a single axis and restricts motion to only one direction—this is crucial for the controlled opening and closing of doors, cabinets, gates, or windows.

This one-axis movement or single degree of freedom is why a standard hinge cannot provide multi-directional motion.

Although there are specialty hinge types such as continuous hinges (piano hinges) and butt hinges that can provide variations in motion or better weight distribution.

There are also various designs and styles of advanced hinges like hospital hinges and double-action spring hinges that can provide more complex motion and possibly use other pins to provide for two-way opening or self-closing features commonly found on doors in commercial and industrial settings.

When selecting hinges, the basic components, namely the leaves, knuckles, and the pin are important. Also, the intended use, load, material type, and finish will also be factors to consider in the selection of hinges.

Hinge Terms

Leaf Length

Leaf length is measured along the axis of the pin and is known as leaf length since it is necessary for calculating load distribution and is particularly important for doors or gates that will carry heavier loads on the hinges to maintain the hinge stable.

Joint Length

Joint length is simply the length of one knuckle or barrel and is important to appreciate as it relates to the load bearing capabilities of the hinge and so on; as well it is important to ensure that the hinge articulation withdraws smoothly.

Barrel Length

Barrel length is the total length of the barrels measured parallel to the pin length. Barrel length can have an impact on the strength of the hinge pivot as well as the shelf life of the hinge itself.

Leaf width

Leaf width is measured perpendicular to the pin axis. A leaf width may allow for calculation on fastening contact area as well. Also allows for a better understanding of the overall stability of the hinge installation.

Open leaf width

Open leaf width is the total width of the hinge measured across the pin and can be a useful measurement for while maintaining alignment when installing door hardware.

Paint Clearance

Paint clearance is the designated space between the outer face of the knuckles and the face of the adjacent edge of the leaf. This enables paint or coatings without restricting hinge movement, which is an important specification in decorative and industrial hinges.

Side Play

Side play refers to the amount of lateral movement of the leaves perpendicular to the pin. High-performance hinges should have minimal side play to minimize sag and misalignment, and to provide longevity in extreme use.

End Play

This is how far the axial movement of the leaves actually goes. Any excessive end play can produce horizontal misalignment and premature hinge failure, as such, accurate manufacture is essential for commercial hinges and heavy hardware.

Pitch

Pitch is the distance between the end of one knuckle and the end of the adjacent knuckle on the same leaf—a detail that affects hinge flexibility and smooth rotation.

Leaf Material

The most frequent materials utilized in hinge leaves will include those materials that are ingrained in “experience,” such as steel, stainless steel, aluminum, brass, and bronze, which each offer different characteristics which can influence hinge strength, corrosion resistance, and appearance to the consumer.

For example, while stainless steel hinges are often recommended for exterior doors and generally for marine or ocean applications based on the durability of the steel and resistance to rust, brass and bronze could be used for decorative purposes to enhance the appearance of furniture or cabinet hardware.

Selecting which leaf material to use is dependent on the environment (interior vs. exterior), appearance desired, load rating, or maintenance performed, etc.

Gauge

Gauge is the term used for thickness of the leaves, either measured in millimeters or gauge numbers. It is important that the leaf gauge is correct, because the hinge must support the required load without bending or distortion. This is especially true for entry doors and industrial hinge applications.

Slop

Slop describes the loose angular movement of the leaves relative to the pin. Minimal slop is desirable for a tight fit and smooth operation and, to a high degree, will improve the security and longevity of the door.

Standard Assembled

In this configuration, the leaves are flat when open and lie on the same plane. Standard assembled relates to a single hinge door configuration. Standard assembled hinges are used commonly on residential doors, cabinets, and light to medium duty applications.

Reverse Assembled

In this fitting, the leaves are positioned laterally from opposite sides of the pin. Reverse assembled hinges typically cannot close the leaves in parallel. This arrangement is frequently used in speciality or custom hardware solution designs, where a certain motion will be utililzed.

End Plate

End plate is the axial travel between the leaves parallel to the pin axis. The end plate allows the leaves to rotate smoothly and without binding, and is indicated by the amount of distance between knuckles when the leaves are flat/parallel to each other.

Proper end plate tolerance is important in high precision hinges for proper smooth and reliable action of hinges .

Hinge Width

Hinge width refers to the measurement from one side of the leaf to the opposite side, measured perpendicular to the pin.

Knowing the hinge width is important for determining hinge selection for doors, gates, and cabinets by knowing the amount of coverage available from the hinge for proper secure installation.

Hinge Length

Leaf length, or length measured in parallel to the pin, can affect load carrying and distribution conditions, along with aesthetics of architectural hardware.

Knuckle Length

Knuckle length, or length measured in parallel to the pin, maintains knuckle length which affects strength and durability of residential and industrial hinges.

Knuckle Pitch

Knuckle pitch refers to the distance between the end of one knuckle and the same end of the adjacent knuckle along the same leaf side, which determines total movement and stability of the knuckle.

Door Stop

Door stop refers to the allowable angular movement or loose movement of the leaf relative to the pin. Much like knuckle pitch, having control of door stop can help prevent over-rotation that can lead to possible damage of the door hinge mechanism and surrounding surfaces.

To obtain more information regarding hinge selection, installation procedures or maintenance practices you may want to consult with a door hardware specialist or installation professional.

Always check product specifications (weights, finishes, certification of materials) when assessing or purchasing hinges – to ensure performance and standards.

(If you want more detailed performance specifications or test protocols, search for materials from a recognized industry organization or association of building hardware comprising professionals).

What Are Some Things to Consider When Purchasing Hinges

When specifying a hinge for purchase, there are several things to consider. Hinging mechanisms, due to their load bearing responsibilities for the external forces and the moving body can represent an undesirable point-of-failure in the mechanism assembly.

The hinge will undergo fatigue from use/dynamic loading and this can cause sagging in the door or gate over time.

Finally, hinges also have limits for maximum thickness as well based on the limitations of manufacturing, as well as space limits. It is important to specify the hinge with the correct dimension, material and mechanical properties for the intended purpose, so that it is appropriate for use.

Load

When specifying a hinge, an important consideration is the load it is required to carry because this will determine the material(s) and size required for the application.

When determining the load, you have to consider the weight of the moving part (normally the part the hinge is supporting), along with any external or dynamic loads.

The center of gravity of the door will create a moment, or torque on the hinge that can create sag, elemetarlhy, if it is a wide, heavy door.

Required or Allowable End Play

Some hinges have limitations on their angular motion such as the geared continuous hinge. The movement can be anywhere leaning towards a full 180° or only having to hinge about 90° depending on what the device is.

Determine if there is space to accommodate the swing of the door or moving part, as well as if the swing of the door or moving part impacts the accessibility through that door. There are different hinges to selecting from, depending on the application.

Depending on what is required for the movement these may need to be tensioned or spring-loaded type of hinges to allow the moving part to remain fixed in place. A common example of friction hinges are laptop covers, camera supports, and ventilation screens.

Hinge Orientation

Logistics or spring-loaded hinges might when predetermined motion is required to keep the moving piece from moving to a stationary position. Friction hinges are a common feature in laptop covers, camera tripods, exhaust ventilation screens and so on.

Installation

Another key consideration is how the hinge is to be secured to the moving and fixed parts. A hinge can be welded, bolted, or screwed to the frame, depending on the service type or load it must support. A hinge can be mounted in a variety of ways, including surface mounted, concealed, flush, overlay, etc.

Aesthetics

Furniture and door hinges frequently utilize decorative elements. This could be in the form of some decorative shapes, such as butterfly and strap hinges, but it may also mean that aesthetics would require hinges to be hidden altogether to give furniture a clean, uninterrupted appearance.

Hinge Corrosion Resistance

The environment, whether outdoors or indoors, dictates the material used for the hinge. If the hinge requires corrosion resistance and high strength, then stainless steel is favored (especially in salt water).

Plastic materials also resist corrosion, but do not have the high strength of metal materials. When stainless steel is too expensive galvanized steel provides a good alternative. Brass and bronze resist the outdoor elements and are frequently chosen for their decorative qualities because of their natural patina.

Additional Features

Additional features are specific features that allow a hinge to perform certain tasks, such as springs and pneumatic dampers in spring-loaded hinges. A hinge design can have many features such as pins, grease fittings, bearings, bushings, screw covers, etc.

Common Hinge Manufacturing Processes

Hinges can be made using several different processes (i.e. casting, extruding, forming, or milling). Each process has its own distinct advantages. The process is selected on the basis of the hinge profile, material, cost, and technology available.

For example, forming hinges can be done cost-effectively with reasonable tolerances, and with relative ease and mass-production viability; however, forming results in a component with non-acceptable strength.

If the hinge is for a heavy-duty situation, milling or casting will allow for a stronger product to be produced.

Casting

Casting is a method of making products with liquid metal that is poured into a mold cavity that defines the shape of product. Casting is one of the original ways of metals manufacturing used to make hinges.

First, the desired shape for the hinge must be constructed out of wood, metal, plastic or plaster called a pattern. For the barrel, a sand (or metal) figure can be used to create the hollow interior.

The mold is prepared by packing a special sand around the pattern within a frame called a flask. Once the sand is packed, the hinge pattern is withdrawn leaving a cavity in the mold.

The molten metal can now be poured into the cavity and allowed to solidify. When solidification is finished, the mold is broken open and sand is removed from the casting. The cast hinge can be cleaned, smoothed, and heat-treated to improve its properties.

Extrusion

Extrusion is a metalworking process (also used for plastics) whereby metal is forced through a shape (die) to form a specific profile across the section, which is consistent along the entire length.

The extruded metal is then milled and cut to whatever required leaf length and pitch for butt hinges, but not for geared continuous hinges since they are shaped equally and uniformly across their section.

Aluminum is the most common material used for extruded hinges, and an increase in the hinge gauge can also be achieved by designing the die with thicker hollow sections, ultimately creating a stronger and more robust hinge.

Forming (Stamping)

Hinge is made from metal and starts with a blank piece cut from a sheet that is then plastically deformed with the help of rollers (and other tools referred to as dies).

Metal forming is among the oldest forms of metalworking alongside casting, and without the concepts of metal forming and hot forging it would be apparent that many concepts in metallurgic design would be hard to apply without this understanding.

A well-known forming example is found in stamping where a blank piece of metal is stamped into a die that is rigorously designed to provide the necessary pressure to produce the hinge shape.

Stamped hinges provide great accuracy in dimensions, and thus they are inexpensive compared to cast or extruded hinges. Also, cold formed items improve the gauge because of hardening in the process.

However, there is limitations to forming hinges and the limitation is design gauge; as plate thickness increases it becomes increasingly impractical to form the hinge.

Cutting or Milling

This process entails cutting away excess material from a metal workpiece by means of lathes, shapers, drills, or milling machines.

Milling is particularly suited for making hinges because it can create hinges more accurate than painted or cast hinges. Milled hinges are generally thicker than the same hinge made by casting and extrusion methods.

Once the hinge is shaped, secondary processes are used to obtain a more useful hinge. Secondary processes include heat treatment, galvanizing, coating, painting and polishing. Heat treatment gives the desired mechanical properties such as toughness, strength and hardness.

Galvanizing, coating and painting assist with corrosion resistance especially in outside environments. Polishing, burnishing and buffing are done to provide a decorative finish to hinges.

Installation of Hinges

One thing must be considered before installing hinges. It is important to maximize the distance between two hinges, as it helps to minimize the load capacities and prevent door sagging.

Applications of Hinge

Hinges are used widely in all areas of life from medical, industries, military to agriculture.

- Research indicates that hinges are utilized in several instances from advancing technology to security to protection from external forces and influence.

- Hinges are utilized in the following sectors:

- Health care is the use of hinges in large lead lined doors that are mainly for radiation and neutron shielding, vault doors and medical devices such as ovens and sterilizing devices.

- In a research and development capacity it is evident that hinges are used on heavy doors to shield laboratories from radiation contamination.

- In the military and defense sector hinges are used in armored vehicles, carriers and heavy doors for secure sites.

- Hinges are also prevalent in the residential and commercial sector in doors, windows, cupboards, TV racks and many home products.

- Heavy duty hinges are used in chemical plants for heavy processing containers to protect their surroundings.

- Hinges are also used in locking and maintaining the security of shipping containers.

- Hinges are regularly used in heavy gates for example in lock and hinging in sites in the petroleum or gas sector.

- Hinges are widely used on illuminated panels for example, LCD and laptop screens and illuminated wall cladding.

- Some marine devices and ships also contain hinges in the doors to enable the ease of the load and unload of heavy doors.

- There are also hinges and different attachments used in agricultural equipment and on construction sites for gates and on equipment.

Conclusion

- Hinges connect two bodies, typically one stationary and one mobile which allows for angular motion along one axis, while preventing translation and rotation about the other two axis.

- Hinges of various design types exist but each design is for a specific application. Most hinges are based on the butt hinge design. Hinges with fundamentally different designs are geared continuous and living hinges.

- Hinges are generally made of three main components, which are leaves, knuckles (or barrels) and a pin. From the properties and characteristics of leaves, knuckles, and pins, design parameters can be determined such as leaf length, end play, pitch, etc.

- Hinges are commonly a weak point in structures. Designing hinges is primarily based on load, end play, aesthetics, and environment. All of these factors can only be satisfied with a balance when designing the most suitable hinge.

- Hinges are manufactured based on hinge design, the materials used, cost and the technology available. The two earliest metalworking processes that produced hinges were forging and casting. As technology advanced other mass production manufactured methods were used, such as, extruded parts, formed parts and machined parts.