What are Linear Bearings?

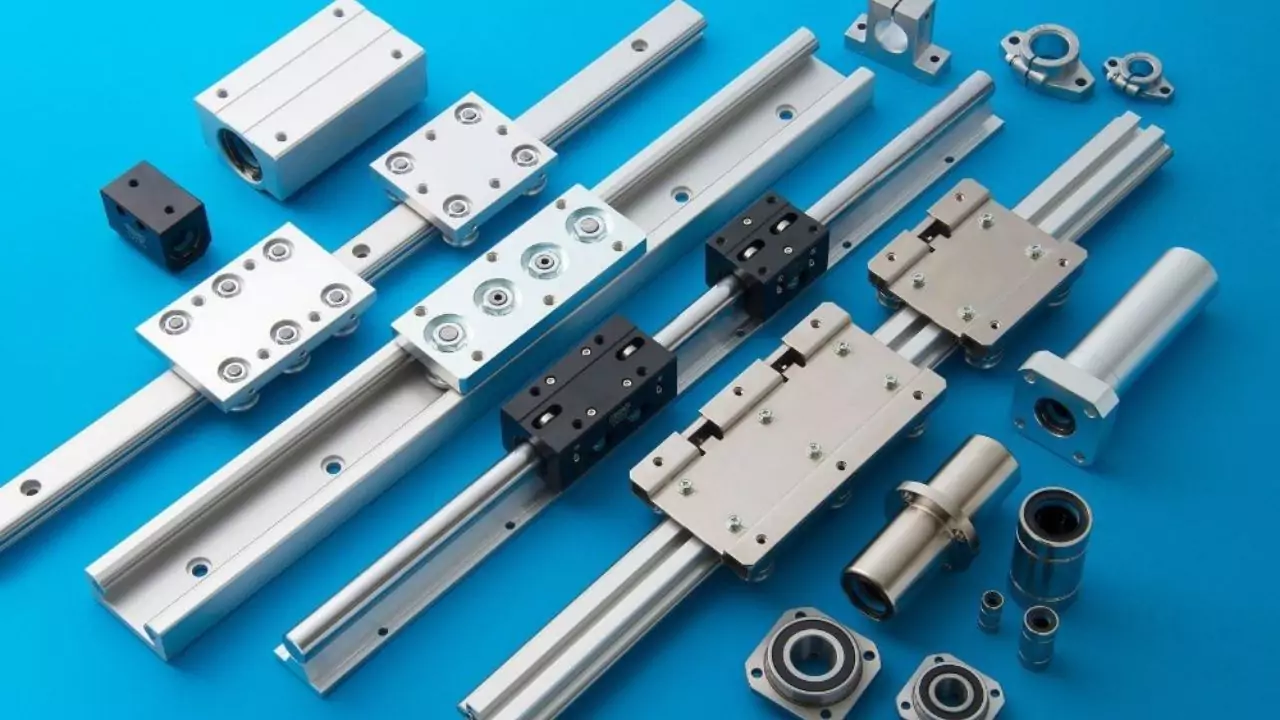

Linear bearings are designed to support the weight of a carriage that is able to only move in a single axis and they provide a low-friction surface to slide so that the carriage can move on guide rails.

The carriage of a linear guide system can only move in a straight line or a curved line along the guide rail which is an integral part of the linear bearing.

Linear bearings come in many types as either a rolling element or a fluid device, to reduce the amount of friction. Linear bearings usually offer good accuracy, a solid mounting point, and smooth motion.

Places linear bearings are used include in 3D printers, sliding doors, and many automated systems that require some sort of rail movement in a controlled manner.

In a linear guide assembly, the linear bearing has an important function to the operation of machinery. Sample applications of linear bearings include cutting machines, XY positioning tables, machine slides, industrial robots, and instrumentation systems.

The function does not have to be with a motor driven ball screw, lead screw, pneumatic cylinders, hydraulic cylinders, or by hand but can only move in one direction along a single axis only in the X – Y plane.

Hydraulic and pneumatic cylinders are an example of components in the XY bed of the CNC milling machine tool.

Generally, there are two types of linear bearings, rolling linear bearings, and plain linear bearings, which we discuss below, with explanations of components, how they function, and some design considerations.

Rolling Linear Bearings

Rolling linear bearings are an important category of industrial automation and precision machinery that allow for smooth and accurate linear travel along a linear guide rail or shaft.

Due to their low friction and ability to travel efficiently, these linear bearings consist of rolling elements, either balls or rollers, that are located between corresponding grooves on the linear guide rails and the bearing.

In terms of friction, rolling bearings create less friction than manufacturing will with bearings, thereby improving wear review and reliability of the bearings operating in critical applications ranging from CNC machines to medical devices and even automated manufacturing equipment.

One aspect of rolling linear bearings that should be considered when selecting the best linear bearing system is the diameter of the balls or rollers which has a direct implication on the max travel speed and the stability of the system.

Larger rolling elements traditionally have higher maximum travel speeds and also increased dynamic load ratings. Another thing to consider is the contact angle, or in rout with which the rolling elements work with the track.

The contact angle ultimately dictates how well the bearing can handle forces. A 45° contact angle is able to balance performance radially, reverse radially, and laterally which allows for flexibility when a scenario will involve loads from more than one direction even under unfavorable conditions.

A contact angle of about 45° increases the performance of the radial loads while decreasing the performance of the lateral loads.

Rolling linear bearings are produced in several specialized designs and configurations of rolling linear bearings. Each category is classified by unique structural and material considerations to be specific to intended setup or operating environment.

Understanding these engineering differences is a very important consideration for ensuring ideal motion control, maximum life, and minimum maintenance in demanding industrial settings.

Geometry of the Rolling Elements

Linear Ball Bearings

Linear ball bearings (or ball bearings) utilize spherical rolling elements commonly made from hardened steel, or advanced ceramics.

Spherical geometry is highly advantageous because it offers low rolling resistance, precise linear guidance, and repeatable accuracy considered essential to automation systems, robots, and medical diagnostic equipment, and linear ball bearings have the flexibility to accommodate a wide variety of linear motion applications that require high levels of efficiency, predictable, repeatable placement, and minimal frictional loss.

Ball bearings have the added benefit of being highly responsive, generate low noise levels, and are considered to have the highest operational speeds of any roller type. High-speed bearings are generally preferred where long-life and performance matter most.

Linear Bearings with Cylindrical Rolling Elements

Cylindrical shaped rollers are featured in their design, these linear bearings (including linear roller bearings) are designed for greater load capacity, rigidity, and better resistance to shock than a ball type. They have a longer rolling contact which distributes the load over a larger area.

The rollers are suited for heavy-duty linear motion such as material handling, packaging machinery, and automation in construction a machine with any bearing has a clear trade off for increased durability and strength is an additional amount of friction during the operation, this is due to this bearing having a larger contact area and having to be well aligned in order to prevent uneven wear or misalignment.

Needle Linear Bearings

Needle linear bearings use thin cylindrical rollers known as needles that have a high L/D ratio (3:1 to 10:1); unique profile allows the highest area of contact that drastically improves load distribution, rigidity, and deflection.

Their profile and strength for radial loads permits their use in restricted space applications that require extreme precision in industrial machinery, automated assembly lines, and transportation equipment.

Needle roller bearings are often used when maximum load capacity, smooth operation, and long life expectancy are essential.

Track Geometry

The geometry of the track profile is a critical factor in defining the load interaction of balls or rollers with the raceway of the bearing.

Because track design influences the number of contact points, the total load capacity of the system, and the friction coefficient, the right track geometry is critical for achieving functionality in high-speed automation, material transferring gantries, or motion control systems.

Gothic Arc Profile

The gothic arch track profile establishes four discrete contact points between the ball and the raceway, thus providing better moment load capability and compactness of installation in comparison to the circular arc profile with similar dimensions.

This allows manufacturers to create more compact logical solutions without sacrifing the rigidity needed for precise positioning or absorptive capacity applications.

An additional complexity arises from additional contact points greater differential slip, requiring greater frictional force to overcome.

This profile is preferred in applications involving advanced CNC machinery and semiconductor automation where instantaneous resistance to moment loads is critical.

Circular Arc Profile

The circular arc profile reduces contact to two points (one at each groove on each mating surface) thus reducing differences in slip and friction losses. This results in smoother, and quieter motion, but at somewhat of a sacrifice to load-carrying ability compared with the gothic arc.

Circular arc profiles are typically used in laboratory automation, instrument rails, and other applications specifically concerned with smooth, precise travel rather than total load capacity.

Linear Guide Profile Shapes

The decision on linear guide rails was determined by the linear guide rail profile, which determines the rigidity, support, and allowable installation requirements.

By determining the proper bearing and guide rail geometry, facilities managers and machine designers can ensure both longevity and precise motion control in their environment with automation or production.

Round Rail

Round rail profile linear guides, along with their accompanying linear ball bushings, utilize cylindrical shafts to achieve linear travel. The linear ball bushing surrounds the shaft and moves along the shaft axially using recirculating balls to provide a frictionless manner of travel.

This form of assembly is highly adaptable to shaft misalignment in addition to being easy to assemble, economical, and gaining increasing popularity among users in 3D printers, laboratory instruments, and electronics fabrication.

Ball splines can be considered a special form of linear ball bushing. Within ball splines, the shaft will also utilize axial grooves that are matched with suitable grooves on the spline nut. Together, the grooves prevent the shaft from rotating while allowing it to transmit torque.

Ball splines are rated for greater moment loads and can reasonably support overhung loads. Ball splines are uniquely suited for robotic arms, automated tooling, and transfer equipment that requires the differential freedom of linear and rotational movement but also carry heavy loads.

Square Rail

Square rail profile linear guides, or profile rail guides, consist of rolling elements that ride on flat rail surfaces with square edges. These sturdy systems are selected for their extraordinary rigidity, high load rating, low deflection under point loads, and effective vibration dampening.

In circumstances where maximum accuracy, stiffness and a higher moment capacity are essential, such as CNC machines, linear actuators, and industrial motion platforms, they outperform round rail designs.

Square rail systems have distinct advantages in automated manufacturing lines and high-precision positioning equipment when space is limited and lateral stability is essential.

Vee Linear Guides

Systems engineered with guide roller technology utilize precision-ground rollers that each have ball bearings, running along steel track rails with a unique V-shaped edge – a feature focused on misaligned tolerance and the ability to move debris.

V-guide rail technology was developed to provide a low rolling friction surface with a quieter drive, while the sealed rollers protection from contamination.

This combination of features and characteristics is why V-guide rail technology is being specified for use in industrial automation, food processing machinery, packaging machinery, and any situation with high dust or particulate levels.

V-guide rail technology provides exceptional service in applications requiring minimum maintenance, and quick installation, while holding up to harsh conditions.

While DualVee guides provide great adaptability, even in high-duty, low-noise, and contaminant-heavy environments, they provide smooth, constant, and lasting service, where other guide features and technology may have already failed.

The flexibility and modularity of V-guide rails provide lots of options to build a customized way-path along its length, ultimately shortening downtime and maximizing machine throughput in demanding production conditions.

Drawer Slide Guide System

Drawer slide and guide systems focus on practical solutions and cost, featuring a C-shaped slide with a C-shaped carriage made of sheet metal.

Each carriage moves on two sets of intermediate ball bearings along both sides, providing smooth and quiet motion for medium load linear motion across moderate distances.

Unlike profile rail systems that need recirculating balls, drawer slides have ball cages that keep the balls inside the carriage. The systems are reliable for movement in cabinetry, consumer electronics, and moderate-duty industrial installations where smooth sliding and access are the most important application considerations.

As with profile rail systems, users selecting a drawer slides or guide system should weigh their options based on the characteristics of their applications; load rating, accuracy, travel extension, and corrosion resistance, for example.

Recirculating or Non-Recirculating Linear Bearings

Recirculating Linear Bearings

Recirculating linear bearings incorporate rolling elements (balls or rollers) that execute a loop through a continuous circuit within the bearing assembly.

Because of this design, the linear bearing carriage can traverse the entire length of the guide rail, giving the system unlimited travel distance, used in applications such as automation, conveyor lines, and large machinery.

Recirculating bearings are composed of multiple raceways, which together increase load capacity and performance life through extended cycling.

To allow for reliable system performance with predictable automation control, engineers and plant operators need to identify how recirculating linear guides will react to torsional and dynamic forces.

The raceway where the linear channel of balls or roller exist, not only affects distance travelled, but also the torsional stability of the linear guide, and tolerance level that can be maintained when the system is under heavy acceleration and deceleration with inconsistent loadings.

When considering recirculating guides, engineers have to examine expected duty cycles, lubrication levels, and potential contamination exposure, which have important implications for the life cycle and precision of the linear guide.

Face-to-Face Arrangement

In a face-to-face (X-pattern) layout, rolling elements provide inward contact with the guide rails, creating a symmetrical structure in the pre-load fitment so that the load performance is uniform in all planes, which is optimal for balanced multi-axis motion applications where moment tipping, is not a key requirement.

This is typically the rail layout option the linear motion stages, pick-and-place robots, and precision inspection systems because of its predictable response in terms of motion, and its ability for smooth motion.

Back-to-Back Arrangement

The back-to-back (O-pattern) alignment of the rolling elements orients the applicable rolling elements outward, which increases the overall moment load resistance and stiffness of the system.

They can offer strong resistance to imposed loads combined with good rigidity to the overall assembly, making back to back bearings the preferred choice for applications with significant side loads or long spans, such as in large format CNC routers, industrial gantries, and similar material transfer systems.

Leverage is maximized with back to back guides; this configuration often becomes the standard in heavy duty motion control and high throughput production environments.

Non-Recirculating Linear Bearings

Non-recirculating linear bearings incorporate non-recirculating stationary rollers or balls that lay firmly within a cage (retainer or separator) inside the linear bearing housing.

The cage holds the rolling elements at intervals to minimize direct contact, limit the friction, and avoid any interferences in placement, including maximum element spacing.

These bearings are typically manufactured from high-grade plastic or stainless steel provide low friction, are silent, and provide consistent linear travel within linear motion.

The linear travel distributes some bearings at most to its maximum stroke of approximately 1 to 2 percent.

Non-recirculating linear bearings typically provide for complete rigidity and accuracy, which makes them ideal in applications like optical stages, metrology equipment, and other high-precision automation or manual applications that require short-range (less than 12 in) and maintenance-free with no backlash.

The length of the linear travel is defined by the overall length of the linear bearing, and the rolling elements provide for smooth and accurate travel while supporting substantial static and dynamic loads.

When selecting a recirculating vs. non-recirculating linear bearings, the selection is dependent on a set of application-specific criteria that include stroke length, load, precision, and expected lifetime.

Non-recirculating linear bearings come in the following types:

Non-Recirculating Linear Ball Bearings

The devices contain steel balls constrained within precision cages with circular or gothic arc tracks for smooth, vibration-free operation.

Their compact size is particularly advantageous for miniaturized linear positioning stages, or elsewhere where space, low noise and high precision is critical as in semiconductor manufacture and laboratory automation.

Flat-Type Roller Bearings

Flat-type roller bearings utilize cylindrical or needle rollers positioned along an axis perpendicular to the direction of travel in order to maximize the surface contact area in use.

By providing additional surface contact area, flat-type roller bearings can sustain greater loads while operating along a flat guideway.

This bearing type would be suited to many applications including high tolerance part manufacturing cells, surface grinding tables, load-bearing transfer tracks, etc., where consistent alignment and limited vertical flexture are paramount.

V-Type Roller Bearings

The V-type roller bearings have a V-shaped groove – usually at 90° – with a row of cylindrical/needle rollers on each flank.

This complementary angular design guarantees consistency in guidance and stability, meaning they can be utilized in transport systems, x-y positional tables, or automated inspection lines, where correct alignment and tracking are required, can use the V-type roller bearings.

Crossed Roller Bearings

Crossed roller bearings utilize cylinders oriented in alternating positions that create a criss-cross assembly with each roller axis set at 90°to neighboring rollers.

This design produces excellent rigidity, smooth motion, maximum moment load capacities, and great vibration resistance. Few bearings provide the level of complexity that crossed roller bearings entail; assembly is difficult, and the handling of bearings must be exact during assembly process.

However, the performance advantages for advanced robotics, coordinate measuring machines (CMMs) and high definition imaging constructions where expected motion accuracy and repeatability must be preserved make crossed roller bearings the ideal choice.

What are Plain Linear Bearings?

Plain linear bearings are vital elements for motion control applications and automation systems. Plain linear bearings operate on the force of direct sliding contact between two surfaces, without the assistance of rolling elements like balls or rollers.

Plain linear bearings have a much simpler construction and direct operating method compared to other bearing types such as roller linear bearings or ball bushings and in many applications cost substantially less when compared to other linear bearing constructions.

The relatively larger contact area between the two surfaces of a plain linear bearing allows loads to be distributed over a larger area, produce lower surface pressure and support higher static and dynamic loads, reduce the weight of an overall system because the bearing to support static loads are lower than others and able to absorb forces from shock to and damp vibrations.

These unique characteristics and factors make a plain linear bearing mechanism an effective solution where load capacity, low maintenance, and tolerance to difficult environments is required.

Plain linear bearings inherently have higher friction compared to rolling element bearings. Increased friction decreases linear speed of travel, and leads to increased wear so periodic lubrication is always needed for successful operation and to increase bearing lifespan.

In order to improve sliding characteristics and reduce the coefficient of friction, many manufacturers will produce bearings from materials with better sliding characteristics, as well as employ solid lubricants or surfaces with a self-lubricating coatings like PTFE or bronze composites.

Plain linear bearings ordinarily have poorer travel accuracy and repeatability compared to other rolling element type bearings so therefore they would not be conducive on high-accurate linear guideways or systems like CNC machines, or metrology systems compared to recirculating ball bearings or cross-roller slides.

The differences of the plain linear bearing types along with their respective advantages, disadvantages and best-fit applications are important for design engineers, machinery builders and automation professionals who are looking for optimal functionality and reliability regarding their industrial automation, robotics and machinery designs.

Plain linear bearings include the following types:

Box-Way Slides

Box-way slides, also known as box type linear bearings, consist of a T-shaped profile made up of a fixed base (guide rail) and a moving saddle (also referred to as a carriage or slide). The base is used to construct a rigid load bearing surface, against which the saddle slides and is moved against.

Between the base and saddle are adjustable gib plates and sometimes referred to as wear plates, which are designed to give precise preloading, clearance, and to add rigidity for the heavy duty application.

Boxway slides provide greater load capacity and vibration resistance than other linear guideways due to the large contact area between the carriage and rail.

Due to their features box-way slides are widely used in heavy duty CNC machines, milling machines, and in the industrial automation sector or where interference and high stiffness, good shock absorbing ability is required and excellent life expectancy when used in frequent applications.

Dovetail Slides

A dovetail slide is a linear bearing mechanism that consists of a base with a V-shaped tongue (the male) that engages a corresponding saddle (the female) that provides stable and continuous sliding contact.

The strong design and full contact design provide load ratings, repeatability, reliability, and resistance to contamination for demanding applications.

Dovetail slides cannot generally be adjusted for preload, as box-way slides can. However, the gib plates, or set-screws, on the saddle can typically be adjusted for clearance and wear that helps maintain precision operation.

Dovetail slides are reasonable for use in manually driven positioning stages, woodworking machines, production machines, precision instruments, and fixtures where repeatable linear motion and rigid load support is desired.

Linear Sleeve Bearings

Linear sleeve bearings are also known as plain bushings, plain sleeve bearings, or journal bushings, and are cylindrical bodies that support a shaft (journal or guide rail) that slides along the lubricated, inner surface of the bearing.

Typical sleeve bearing materials are bronze, polymer composites, PTFE (Teflon), and sintered metals with embedded lubricants to minimize maintenance.

These linear plain bearings provide quiet, low maintenance linear movement, and can accommodate both axial and radial loads; however, they have lower load capacity and stiffness than box-way and dovetail slides.

They are primarily used in light- to medium-duty applications—such as 3D printers, packaging machines, conveyor machines, and consumer products—where cost, silent operation, and ease of replacement is important.

It is important to properly size and select materials in order to maximize sleeve bearing life and reduce wear in high-cycle or abrasive duty applications.

Non-Contact Linear Bearings commonly referred to as zero-contact or air-lubricated linear guides are linear bearings which avoid any mechanical contact for the carriage and guide rails.

By eliminating friction from the operating environment, this type of advanced bearing ideally offers long service life, reduced maintenance requirement, reduced noise and higher linear speeds than comparable sliding contact guided systems.

Non-contact linear bearings are valuable in applications such as semiconductor manufacturing, clean room environments, and high-speed automation, where smooth and precise linear motion are critical. The two types of non-contact linear bearings discussed in this section include:

Fluid Linear Bearings

Fluid linear bearings, also known as hydrostatic or fluid film bearings, employ a thin film of pressurized fluids, most frequently oil, air, or water, to separate the bearing surfaces and minimize physical contact. There are two basic designs:

- Hydrostatic fluid bearings: Pumps are used to actively supply the fluid enough to maintain constant pressure, which lifts the carriage and provides exceptional load support (especially at slower speeds).

- Hydrodynamic fluid bearings: Generate fluid pressure by the relative motion between the carriage and rail, which at speed creates a load-bearing film.

These linear bearings offer reliable linear movement and relatively high values of load, while they minimize wear, create little to no vibration, and are relatively noiseless.

In that respect they are most appropriate for high speed and high precision applications like inspection equipment, wafer handling systems, and other modern manufacturing equipment.

On the other hand, there are limitations to their usage such as a high initial cost, continuous maintenance, potential hostile sensitivities, and temperature fluctuations or contamination.

Magnetic Linear Bearings

Magnetic linear bearings, or maglev bearings, use strong magnetic forces to suspend the moving carriage from the guide rail, creating truly contact-free, frictionless linear motion.

This type of motion offers the smoothest motion, very accurate position sensing, no wear characteristics even under the most extreme of circumstances, and is appropriate for very accurate and sophisticated uses.

Magnetic linear bearings tend to be most effective in applications involving high levels of automation, laboratory instrumentation, or within semiconductor fabrication lines where lack of contact will give not only the most reliable motion system but will minimize amounts of time required to operate the system.

It is important to understand that while there are many benefits to magnetic linear bearings, including capacity for heavy loads, and mechanial wear, there will also be EMI (electromagnetic interference) from the magnetic linear bearings and surrounding systems on nearby electronic devices or sensitive instrumentation.

In addition electromagnetic systems can be complicated, costly, and in some cases, unpalatable to use in a process.

When deciding on the appropriate linear bearing type – plain, fluid or magnetic – it is important to look at all aspects of the application, including load, speed, system accuracy, work environment, lubrication, and cost.

These linear bearings each come with their own specific set of advantages and disadvantages which will allow a knowledgeable engineer or manufacturer to select components to achieve the best component life, machinery performance, and accurate, reliable linear servomotion.

In addition linear motion specialists, such as bearing manufacturers, can help capture the spectrum of technical specification, material compatibility, and maintenance expectation of the various types of linear bearing systems.

What materials are used in the construction of linear bearings?

Linear bearing components are made from the following materials:

Steel

Steel, which is an alloy of carbon and iron, is the most frequently used material for linear bearings. Steel bearings have very good mechanical properties that make them ideal for linear bearings including strength and stiffness, which allow them to support heavy loads while providing smooth and accurate motion.

Carbon steel and stainless steel are common steel used in linear bearings, while the hardness of carbon steel increased as the carbon content increases, and this can affect the performance of the linear bearings.

Aluminum

Aluminum is a strong, lightweight metal which is also corrosion and chemical resistant. Although aluminum is softer and less expensive than other metals like steel, aluminum linear bearings are just as capable of moving smoothly and precisely, even if they aren’t rated for as much load.

Plastics

Plastic linear bearings have softer materials, are less expensive, and have a lower coefficient of friction than metal bearings.

They are generally made with common plastics such as nylon, polyethylene or PVDF, often coated with self-lubricating materials such as PTFE, and they may also have a fiber or filler reinforcement. The bearing may also be made of a softer shaft material.

They generally have lower load capacities than metal bearings and are limited to typical room temperature temperatures.

Bronze

Bronze is an alloy of copper and zinc, to which additional elements, such as manganese and phosphorus, have been added. Bronze is a softer metal. Bronze linear bearings can support a much higher load than plastic bearings.

The downside of bronze bearings is that because they are made of metal materials, it is a metal-on-metal bearing and will generate more friction than those manufactured from plastic materials.

A metal-to-metal bearing will always require more attention than plastic, and, therefore, maintenance (due to the need to lubricate).

Ceramics

Ceramic linear bearings are generally made from silicon nitride, aluminum oxide, zirconium oxide, and silicon carbide. Ceramic bearings provide very high rigidity, thus they provide for very precise travel and precision even at high speeds.

They are the hardest material and therefore make for the longest service life and have good abrasion resistance while producing very little in the way of particle emissions from friction of component parts.

Ceramic bearings could be used in a vacuum setting and also in settings in which electrostatic discharge (ESD)-sensitivity exists.

In recirculating linear bearings, ceramic rolling element(s) will support higher speeds.

Composite Materials

Composite bearings consist of metal backing and a plastic sleeve or PTFE liner, where the plastic removes the lubrication and metal-to-metal contact for the linear bearing but maintains the high load capacity. The backing also aids in the dissipation of heat.

It is okay to have different bearing and guide rail materials. The guide rail material should typically be more durable to friction reduction.

Wear will occur solely at the contact surface of the linear bearing where it is softer, while guide rails, shafts, and bases (for plain linear bearings) will be made from harder materials (i.e. hardened steel, ground steel, or anodized aluminum).

What should you consider when selecting and operating linear bearings?

We have covered the different types of linear bearings, construction materials, and the effect of construction on load capability, speed and service/predicted life of the bearing. Here are a few more considerations that you should be aware of when selecting, applying and maintaining linear bearings:

PV Rating

PV rating is a specification that defines the maximum surface pressure and sliding velocity a linear bearing can endure and still be utilized sufficiently. The PV rating is made up of surface pressure and sliding velocity, which represent heat and wear from friction.

For instance, increasing the speed at which a linear bearing operates can decrease the maximum permissible load capacity of the linear bearing. The PV value is the operating surface pressure multiplied by the speed. The PV value must always be less than the PV rating.

Nature of the Application

Cleanroom

A cleanroom is a controlled environment that minimizes airborne particulates, contaminants, and particles. It is used in manufacturing of consumer products such as food and beverages, pharmaceuticals, semiconductors, electronics, medical devices, and assemblies.

For the cleanroom environment, linear bearings are often found to create a fine dust from metal dust because there are high-speed metal-to-metal contact among the rolling elements, and some recirculating configurations of linear bearings can really produce fine dust under these conditions.

Many times, non-recirculating linear bearings can be selected to control this dust by using cages to separate the rolling elements from each other, reducing dust by separation. In addition to linear bearings, plain linear bearings may also be an option in cleanroom applications.

Another challenge when dealing with cleanroom environments is the lubrication. Many times, the goal is to use as little external lubricant like oil and grease as possible, so as not to contaminate the cleanroom products.

This is one reason that bearings made of plastic or composite materials are often preferred for cleanroom environments. All lubricants that are used must also abide by cleanroom standards, and be used within any washdown or clean-in-place system.

Vacuum Environment

Outgassing is the evacuation of gases and vapors trapped in solid materials through vaporization / sublimation at low pressures, which can cause a rise in pressure in a material’s environment, compromising vacuum ability to reach / maintain vacuum.

Common materials that outgas are plastics, ceramics, porous metals, elastomers and some lubricants.

One way to mitigate outgassing is to use linear bearing materials that have been baked out, which consists of placing materials in an oven at about 200°C for several hours to drive out volatile vapors. It may not be possible to bake out some materials.

Also, lubricants can outgas, so where you have been instructed to use lubricants, it is prudent to use self-lubricating coatings or solid lubricants that are compatible with your vacuum.

Air Linear Bearings

Air linear bearings do not depend on the presence of rolling or sliding elements like a typical mechanical linear bearing.

Rather, air linear bearings support loads with a pressurized air or oil film, thereby eliminating any mechanical contact that creates friction or external heat. Air linear bearings are particularly suitable for high precision and rigid applications.

Types of Air Linear Bearings

There are two forms of air linear bearings, hydrodynamic and hydrostatic bearings, discerned by their types of generating the supporting film; both bearing types use a gas, normally air, to support the applied weight.

In clean rooms, when air quality is an issue, something other than air may be chosen as the supporting gas, such as nitrogen, to prevent moisture from compromising the gas and inducing a corrosive environment.

Hydrodynamic Linear Air Bearings

Hydrodynamic linear bearings utilize a thin film of either fluid or air to support the rotating parts, otherwise known as fluid film bearings. This forces a separation of the stationary surface and the rotating surface, reducing friction and wear, ultimately increasing the life of the bearings.

The gap in hydrodynamic linear bearings created between the surfaces is created by the motion of the bearings themselves. Hydrodynamic linear bearings require some external pressure to ensure there is no friction during startup. Hydrodynamic linear bearings can be designed to support both radial and thrust loads.

Typical examples of hydrodynamic linear bearings will be circumferential groove bearings, pressure bearings, and multiple groove bearings. Some applications using hydrodynamic linear bearings include steam turbines, electric motors, cooling pumps, rock crushers, clutches, blowers, and auxiliary equipment.

Hydrostatic Linear Air Bearings

Hydrostatic linear air bearings utilize a positive air pressure supply to provide a gap between the stationary surface and the rotary surface. This type of bearing is also a fluid film bearing, such as hydrodynamic bearings.

Hydrostatic bearings are known for their stiffness and reliability, allowing their use as effective bearings in high precision machine technologies.

Like hydrodynamic bearings, they are not limited by a lubrication that establishes the relative motion, allowing for them to sustain relatively heavy loads at low speeds and directly control stiffness and damping coefficients.

Benefits of Air Linear Bearings

Fundamentally, the advantage of air linear bearings is the lack of friction, wear, and heat generation due to the absence of mechanical contact between rotating and stationary surfaces.

Since there is no mechanical contact, lubrication is not needed and this greatly reduces particle generation and noise as compared to rolling and sliding bearings.

Air bearings can accomplish higher speeds and accelerations because they do not have recirculating elements. Additionally, their motion is incredibly precise with extremely low scale errors. The load is fully supported by the fluid film; therefore there is high stiffness and accuracy.

Conclusion

- Linear bearings are a type of bearing that support the load of the carriage during its movement in one axis linearly and provide a low friction sliding surface for the guide rail.

- There are two main classes of linear bearings, rolling linear bearings and plain linear bearings.

- Rolling linear bearings have rolling elements in a housing that allow linear motion. The rolling elements in a rolling bearing can be either recirculating or non-recirculating.

- Plain linear bearings, facilitate linear motion by sliding motion and create more significant friction, but they can withstand higher loading capacities.

- Non-contact linear bearings rely on fluid pressure or strong magnetic forces to lift the carriage from the guide rails. They generate a very minimal friction and have an infinite service life.

- Linear bearings are typically made from steel and aluminum. Plain bearings can be made from a wider array of materials which include, but are not exclusive to bronze, plastics, ceramics and composite materials in addition to steel and aluminum. Plain bearings sometimes use multiple materials of varying hardness, to put the wear on the softer component; and there will always be wear as these bearings are sliding through a motion.

- The PV rating is the highest combination of surface pressure and velocity the linear bearing can withstand. Do not exceed the operating PV value over the PV rating.

- Application must be a consideration when selecting a linear bearing.