What Does TRL Mean?

Technology Readiness Levels (TRLs) describe the levels of technical maturity of a technology in the phase of acquisition. TRLs allow engineers to have a common frame of reference for understanding technology maturity regardless of the technical knowledge of the engineer.

TRLs are assigned through a Technology Readiness Assessment (TRA), which looks at the concepts and technology requirements and technology capabilities of a given program.

What Do TRLs Assess?

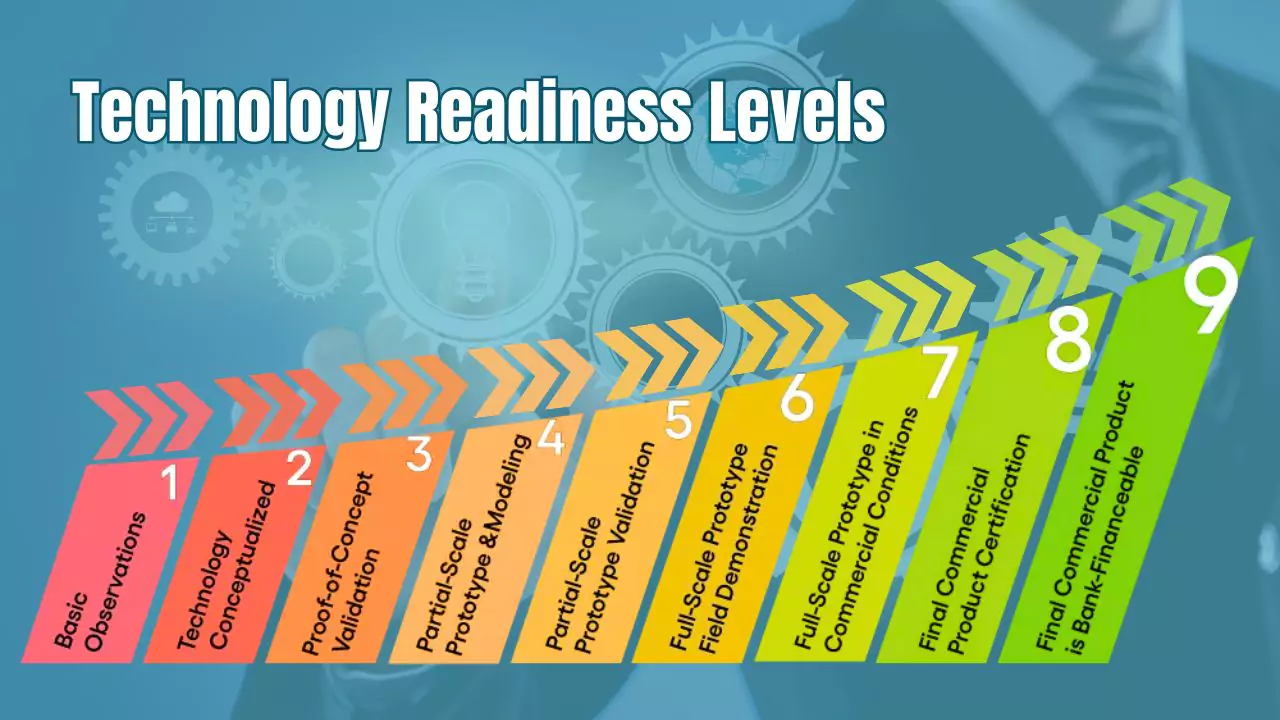

Originally developed by NASA in the 1970s for technologies of space exploration, TRLs assess the level of maturity of a technology throughout the stages of research, development and deployment. TRLs are based on a 1 to 9 scale with 9 being mature.

Many organizations have applied the TRLs for their purposes. Organizations such as the European Union (EU) have taken further steps to standardize the NASA assessment definitions, thus allowing the multiple industry sectors to translate the TRLs – not just in space exploration.

Examples of Technology Readiness Levels

The EU defines the 9 levels as follows:

| TRL | Definition | Example |

| 1 | Basic principles observed | Scientific observations made and reported. An example may be paper-based investigations of the basic properties of technology. |

| 2 | Technology concept formulated | At this stage, the foreseen applications are speculative. An example may be limited, to analytical investigations. |

| 3 | Experimental proof of concept | Research and development have commenced effectively. An example may be studies and laboratory measurements to corroborate analytical predictions. |

| 4 | Technology validated in lab | Technology has been validated through the designed investigation. An example may be analysis of the technology parameter operating range. The findings suggest that the foreseen application performance requirements may be achievable. |

| 5 | Technology validated in relevant environment | Reliability of the technology has increased significantly. An example may involve validation of a semi-integrated system/model of the technology and underlying elements/systems in a simulated environment. |

| 6 | Technology demonstrated in relevant environment | Prototype system validated. An example may be a prototype system/model produced and validated in a simulated environment. |

| 7 | System model or prototype demonstrated in operational environment | A significant step improvement in the technology maturity. An example may be verifying a prototype model/system in an operational environment. |

| 8 | System complete and qualified | System/model produced and qualified. An example may be the knowledge created/EUR from TRL 7 is now being used to manufacture an actual system/model and getting it qualified in the operational environment. In almost all situations, this TRL indicates the end of the development. |

| 9 | Actual system proven in operational environment | System/model has been proven and ready for full commercial deployment. An example may be the actual system/model has been used/successfully deployed for multiple missions by the end users. |

Here is the definition for each TRL so that you can become acquainted with the scale.

Level 1: Basic principles observed and reported

Lowest level of technology readiness. Scientific research begins to be formulated into applied research and development (R&D).

Examples might include paper studies of a technology’s basic properties. Supporting information could include published research that describes the principles in which this technology is based along with references to who, when, and where.

Level 2: Technology concept and/or application formulated

The invention begins. After you have recognised the basic principles, you can develop new practical applications. Applications are speculative and it is possible that you may have no proof or significant analysis to back up your hypotheses.

Examples are limited to analytical studies. Supporting materials include articles, or other references which outline the application under consideration and provide analysis to support the idea.

Level 3: Analytical and experimental proving out of critical function and/or characteristic proof of concept

Active research and development begins. This means analytical studies and laboratory studies to experimentally prove the analytical predictions of separate portions of the technology. Examples are components that are not yet contextually integrated or representative.

Supporting materials could include the outcomes of laboratory experiments that were conducted to measure the parameters of interest and comparisons to the analytical predictions for critical subsystems. References to whom, where, and when were any tests and comparisons performed.

Level 4: Component and/or breadboard validation in a laboratory environment

Basic elements of the technology were put together to validate they work in conjunction with each other. Compared to the eventual system this is relatively “low fidelity”.

Examples of this could be putting together “ad hoc” hardware, in the laboratory. Supporting materials could include concepts for system integration that have been considered and outcomes from testing laboratory scale breadboard(s).

And references to who conducted this work, and when. Also documentation providing a discussion of how the breadboard hardware and test outcomes varied from desired system performance requirements.

Level 5: Component and/or breadboard validation in a relevant environment

Fidelity of the breadboard technology is significantly increased. The basic technology components are integrated with fairly realistic supporting elements so that they can be tested in a role playing scenario.

Examples are integrated components of a laboratory “high-fidelity” test or will take part in supporting laboratory test. In supporting information, the results from the testing of the laboratory breadboard system are integrated with other supportive information into a simulated operational environment.

What is the difference between the “relevant environment” with respect to what it should be in an operational environment? How do the results match expectations? What problems if any occurred? Was the laboratory breadboard system refined to a closer match to intended system targets?

Level 6: System/subsystem model or prototype demonstration in a relevant environment

A representative model or prototype system, which is well beyond that of TRL 5, is tested in a relevant environment. Represents a significant advancement in a technology’s demonstrated readiness.

Examples are tested prototypes in either, high-fidelity laboratory-type environments or, simulated operational environments. Supporting information includes results from laboratory testing of a prototype system that is near performance, weight, and volume of the intended configuration.

What wasn’t representative in the operational environment from the test environment? Who performed the tests? What was the difference in the test from expectations? What problems, if any, were encountered? What are/were the plans, options, or actions to address problems before moving to the next level?

Level 7: System prototype demonstration in an operational environment

Prototype near or at planned operational system. This represents a significant advancement from TRL 6 because it requires demonstration of a real system prototype in an operational environment (for example, in an aircraft, in a vehicle, or in space).

Supporting information includes results from testing a prototype system in an operational environment.

Who conducted the tests? How did the test compare against the intended expectations? What issues, if any, were found? What are/were the plans, options, or actions for resolving issues prior to moving up to the next level?

Level 8: Actual system completed and qualified through test and demonstration

Technology has been demonstrated and proven to work in its final form and in expected conditions. In nearly all cases, this TRL has represented the end of true system development.

Examples include developmental test and evaluation (DT&E) of the system in its intended weapon system to determine whether it meets design specifications.

Supporting information includes results of testing the system in its final configuration under the expected range of environmental conditions in which it will be expected to operate.

Assessment whether it will meet its operational requirements. What issues, if any, were found? What are/were the plans, options, or actions for resolving issues before completion of design?

Level 9: Actual system proven through successful mission operations

Actual use of the technology in its final form and under mission conditions (e.g. in operational test and evaluation (OT&E), using the system in operational mission conditions). Supporting information includes OT&E reports.

Who uses TRLs?

Initially started by NASA, TRLs have been adopted by different organizations such as the United States Department of Energy (DOE), US Department of Defense (DOD), the European Space Agency (ESA) and industries such as oil and gas.

Uses of Technology Readiness Levels

The primary use of technology readiness levels is to assist management with their decision-making regarding the development and transitioning of the technology, and is one of several tools that are needed to manage the evolution of research and development activity in an organization.

Benefits of TRLs, include:

- Provides a common understanding of the technology status

- Manage risk

- Make decisions about technology funding

- Make decisions about transition of technology

Some of the characteristics of TRLs that limit their usefulness:

- Readiness does not necessarily match with appropriateness or maturity of technology

- A more mature product may have more or less readiness for use in a particular system context than a product that is of lower maturity

- Many factors need to be taken into consideration, including the applicability of the products operational environment to the system, and the product-system architectural mismatch

TRL models tend to ignore negative and obsolescence factors. There have been proposals for negative and obsolescent factors to be included in the evaluations.

As for complex technology with multiple stages of development a more detailed model called the Technology Readiness Pathway Matrix has been created, which goes from simple units to applications in society.

This model seeks to demonstrate that a technology’s readiness is based on a much less linear process and is a more complex pathway through society’s application.