What is a Bottle Brush?

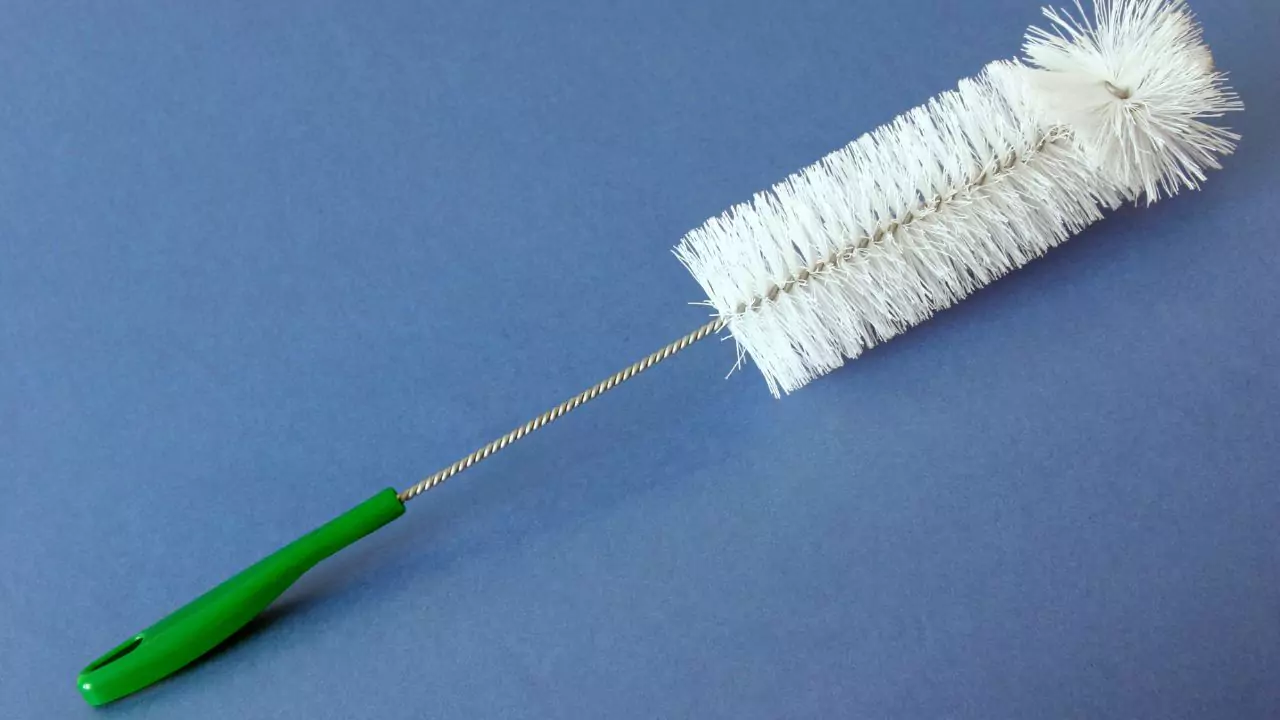

The name bottle brush generally refers to cleaning brushes with flexible bristles, as opposed to a cleaning brush with stiff bristles. A bottle brush is characterized by a flexible and adaptable set of bristles which attach to a long handle or stem made of plastic, wood, or wire.

Bristles may cover some of the handle in a tubular form, or occupy space only several inches from the end of the brush. The manner in which the bristles are attached can vary based on the manufacturing process.

Bottle brushes are strongly associated with cleaning bottles, but they can be used for many different purposes.

Although a bottle brush is typically long with bristle at one end, the configuration and design of the bristles can vary between brushes, and some bottle brushes are for specific use.

Bottle brushes, through their long bristles, can easily clean bottles, because of access to area that other brushes or sprays cannot reach. In addition to cleaning bottles, they can be used to clean test tubes, rubber hoses, cylinders, and other tubular or similar-shaped items.

Bottle brushes can be used in industrial, kitchen, or domestic situations, and each bottle brush is made for a specific use or application.

How Bottle Brushes are Made?

There are many ways to make bottle brushes, including twisting wire, stapling bristles, and inserting bristles in holes in wooden or plastic handles. For each type of brush there will be a proper manufacturing process depending on the type of brush and the application of the brush.

For example, industrial brushes must have a level of sturdiness and durability not typically required for brushes designed to clean general bottles and containers. The durability requirement has bearing on the raw materials and production methods used.

Although they are just a handle, and bristle’s or filaments, engineers design bottle brushes using various material characteristics, in order for the brushes to properly perform.

As innovation and technology evolves, there is a significant demand for more futuristic, durable designs of bottle brushes.

Brush Bristle or Filament Materials

The bristles or filaments are the most important part of all brushes: bristles or filaments typically take three forms: natural, synthetic, and wire.

However, not all filaments are appropriate for bottle brushes, as some filament types cannot accommodate the design needs of the bottle brush.

- Nylon: Nylon is a synthetic filament and is the most commonly used filament. Nylon is the most flexible filament. Nylon is very durable with high abrasion resistance and good bend recovery. It is resistant to common chemicals and has a softening point of 350°F (176.6°C).

- Silicone: Silicone bristles or filaments, are synthetic, and are very flexible and durable. They are very unlikely to scratch the cleaned surface or components.

- Horse hair: A natural material. Horse hair retains its shape for an extended period of time, while remaining soft but durable enough to clean any surface. Horsehair brushes are generally used for the cleaning of bottles. Engineers and material researchers use horsehair due to its strength, stiffness, and length, in addition to being non-conductive.

- Polypropylene: Polypropylene is a cheaper alternative to nylon, however it does not have the same bending characteristics. While wet, it has superior stiffness and is inert to solvents, oils, acids and chemicals.

- Polyester: Polyester has excellent bend recovery, and solvent resistance; it has oxidation properties at high temperatures. Polyester is inert when it is wet or dry, it will not absorb water.

Although the filaments and bristles discussed above are the most standard materials used in manufacturing bottle brushes, they are not the only materials used as manufacturers can and will design their brushes dependent upon criteria and needs.

Brush Handle Materials

Bottle brushes have a variety of handle designs, which serve to support the bristles and allow them to perform best. Important aspects that the handles need to consider are length and material and is produced from wire, plastic or wood.

- Wire: For plastic handles, where the handle is made of wire, bristles are secured via winding or twisting into place with two or four wire-stems to hold the bristles between. Once the bristles are placed, the wires are twisted to secure them.

- Single Stem: For the single stem condition, the bristles are secured between two stem wires, with one across each side of the bristle length.

- Double stem: Double stem bottle brushes are four thicknesses of wireS, the bristles are twisted between the four stems; the outcome is very strong and duty limit.

- Double Spiral: With a double spiral bottle brush, there are four wire stems and two sets of bristles that are twisted together. The fill bristles are orthogonal to each other.

Wooden Brush Handles

Wood-handled bottle brushes are for both the commercial user and the residential user; the bristles are inserted into holes drilled into the handle, and are secured with staples.

This is just one example of the hundreds different types of bottle brushes that are made.

Plastic Brush Handles

In the case of a plastic handled bottle brush, the bristles are inserted into pre-formed holes cut when the handle was molded. The bristles are secured using several methods; for example, wires attached to the bottom of the bristles, glue, or adhesives. The method used varies from manufacturer to manufacturer.

For plastic handles, you will see different types of styles based on their use; there are very heavy-duty bottles brushes designed for commercial kitchens or manufacturing.

Similar to wooden handled brushes, plastic handled brushes can also have single twisted wire bristles secured to the handle. This style is common for plastic handled brushes.

Types Of Bottle Brushes

There are many different types and styles of bottle brushes, as well as various sizes to meet the needs of the applications. Variations can include variety of bristle diameters, types of bristles, handle materials, and length of the brush.

For example, very small bottle brushes used for cleaning delicate equipment have small handles and soft bristles. Powered bottle brushes are made for speed and performance in cleaning large piping, tubing and cylinders.

Handles for any bottle brush can incorporate wood, wire or plastic, with bristles attached in different configurations. In the case of wire brushes, the bristles are twisted into place with a minimum of two pieces of wire.

Twisting the wire in two pieces allows the brush to maintain a slight amount of flexibility. For brushes with a plastic or wood handle, the bristles are inserted into pre-drilled holes in the handle.

Carafe Cleaning Brush

As with all bottle brushes, a carafe cleaning brush is used to clean bottles, jars, glasses, and all types of refreshment serving containers. This brush has a long plastic handle and the bristles are crimped and set with staples.

The bristles are soft, pliable, and must be rigid enough to clean dried liquids. Most carafe bottle brushes have a hole in the top of the handle for convenient store-age.

Test Tube Brush

Cleaning test tubes is a challenge. Any residual cleaning chemical can leach into the next sample, contaminating it and probably ruining any test results.

To insure thorough cleaning of test tubes, test tube bottle brushes are designed with unique features of construction, and are generally smaller than the household bottle brush or the industrial bottle brush.

Many are made of galvanized wire to resist corrosion from chemicals that can dry at the bottom of test tubes.

In addition to the above, test tube bottle brushes have additional bristles, called tufts, at the tip for the specific purpose of dislodging and cleaning materials accumulated at the bottom of test tubes.

Pipe and Tube Bottle Brush

Pipe and tube bottle brushes must be strong, durable, and resilient because they have to remove hard, compacted, or accumulated materials. They have very stiff bristle, and can get into difficult areas, like tees, elbows, valves.

Pipe and tube bottle brushes have long handles, from one foot to two feet. The opening of the bristles on a pipe and tube bottle brush vary based on the design and use of the brush.

Pipe and tube bottle brushes are made from wire that is bent in half, with the bristle material sandwiched in between the rabbit and the hare. The wire is twisted to hold the bristle material in place.

Hook Bottle Brush

The hook bottle brush is designed to be used to clean around bends and curves in piping. The hook bottle brush is designed to be effective in high areas and or awkward reach cleanings.

To aid in durability, and to eliminate materials that would be corrosive or rusting, the wires of a hook bottle brush are made of metals that are rust resistant and corrosion resistant.

Sponge Bottle Brush

A sponge bottle brush has a sponge at its tip, behind the bristles. The sponge will aid in the cleanliness efficiency by adding a scrubbing surface to the brush.

Both sponge and test tube bottle brushes can easily remove particulates that are stuck, and some residual debris on the bottom of any container.

Dairy Bottle Brush

Despite its name, a dairy bottle brush is not limited to dairies, These brushes all have the same basic design in which the bristles are twisted into heavy-gauge steel (galvanized) which provides cleaning capability across many materials. Additionally with their tapered tip, the brushes can be used more flexibly for cleaning.

Like other bottle brushes, dairy bottle brushes are available in many shapes and sizes, and may even have different styles of handles for various cleaning purposes.

Tufted Bottle Brush

These brushes are for heavy-duty cleaning with bristle configuration for commercial/restaurant kitchen use. Soft pliable bristles are tacked tightly at the tip to prevent scratching chapter.

Lengths of bristles are 4 to 7 inches and lengths of handle range from 1 to 2 feet. Tufted bottle brushes can be rugged and robust with plastic, wood, or wire chemical resistant handles.

The radial tip on tufted bottle brushes allows for easy removal of dried deposits from the bottom of bottles, without causing damage to the bottle surfaces.

Some tufted bottle brushes like the folding tip or double tufted brushes are built for entering collapsed into the bottle, and will spread out wider while being pushed inside and can accommodate vessels/gross cleaning with elevation.

Fan Tipped Bottle Brush

Fan tipped brushes are also a versatile tool. They are designed for cleaning both open and closed, cylinders and tubing. Fan tipped brushes may have plastic or looped handles, and may have bristles shaped in a tube that run from the tip of the brush to the handle.

These brushes are ideal for containers that hold acids, petroleum distillates, hydrocarbons, ethyl acetate, or esters because of their polyester split bristles.

The placement of bristles at the fan tip and tube bristle make it so there are, if used correctly, bristles perfectly positioned to allow the cleaning of the bottoms of containers as well as the tops.

Flask Bottle Brush

Flask bottle brushes are designed with an offset shape to clean the curves of the bottom and the shoulders of various bottles and flasks. These brushes have nylon bristles (which come in varying colors, such as black and white) for different cleaning needs.

These eight types of bottle brushes are a small sample of the infinite styles of bottle brushes available. Manufacturers are continually designing new bottle brushes to respond to the changing demands of particular applications and uses.

Things to Consider before Choosing a Bottle Brush.

Bottle Brush Bristle Material

Bottle brush bristles come in various materials and performance used for cleaning different materials. Nylon bristles are one of the most common bristles due to their durability, cost, cleanability, and longevity. However, nylon can be abrasive and does scratch container surfaces.

Silicone bristles can be softer and less abrasive but cannot really be use for more abrasive cleaning. Silicone bristles work well on delicate instruments. Silicone bristles are ideal for cleaning graduated tube, test tubes, or similar.

From a material standpoint, silicone is more expensive than nylon but the form of the bristles in silicone (flexible nub shape), aids in making the cleaning action softer while still working well for many applicatons.

Polyester bristles have a reputation for being very rigid and stiff. They offer cleaning ability of stubborn materials fastened to surfaces.

Polyester bristles can deal with a range of sheens or coatings and can remove solid or hardened materials. Additionally, polyester bristles withstand water to absorb water and are tough.

Characteristics of Bottle Brush Bristles

- Soft – The soft bristles (with soft fibers) are longer than their thicker siblings and, by definition, they are thin making them better suited for fine materials removal.

- Medium – The medium bristles enables wet and dry applications and for large particles removal.

- Stiff – The stiff hardier bristles (also short and thick) are similar to scrub brush bristles, they assist in removing stuck debris and supporting powerful cleaning chemicals.

Bottle Brush Length

Bottle brushes come in several lengths, depending on your needs. The handle length is the biggest consideration for size; handle lengths can range from a couple of inches to two or three feet. The handle is the part of the brush that holds the bristles in place.

Longer handles with thinner bristles, may be useful for applications that require cleaning of pipes or cylinders, while cleaning lab instruments may not require brushes with aggressive fibers.

There are two lengths considerations in bottle brushes: bristles length and handle length. The longest brush is equal to the bristles length plus the handle length.

Also remember that when assessing a brush size; think of the bristle diameter and the diameter of the cleaning item.Bottle brushes that have bristle diameters equivalent to the diameter of the object may be too tight, and thus may not be effective at cleaning.

Bottle Brush Flexibility

Flexibility is not an important consideration for most applications of bottle brushes, but it becomes important when cleaning pipes, valves, elbows, and connectors.

Bottle brushes are designed for specific applications, and the manufacturers will assess if the application requires a curved and flexible bottle brush.

Bottle Brush Handle

Traditionally, bottle brushes were identified simply with wire handles completed with a loop on the handle. For many applications, there are various ways to improve handle types, and still securely fasten the bristles.

When assessing a bottle brush, it is important to consider if the handle is durable; if it is easy to use; and if it is acceptable for the cleaning task.

In industrial applications, handles are often made from either galvanized or stainless steel to ensure no chemical damage occurs.

When using brushes involving food preparation, both the handle and bristles must comply with the rules and regulations set out by the Food and Drug Administration (FDA).

Benefits of Bottle Brushes

Bottle brushes can clean contaminated bottles. Any residue left in a refillable bottle can contaminate the new bottle contents and spoil its contents. Once bottles are emptied and can sit, a little bit of the last contents dry up and, harden at the bottom of the bottle.

To achieve a fully sanitized container, the bottle sides and the bottom must be scrubbed by the bottle brush bristles.

Wet sponges do not offer the kind of scrubbing power that a bottle brush does, and only a bottle brush can offer the ability to access the tiniest areas of any container to remove any type of contaminant.

This is why bottle brushes exist in kitchens, laboratories, bottling plants and food processing sites.

There is really no way to effectively clean an object or space as well as a bottle brush can. Many different cleaning methods have been applied in efforts to decontaminate and remove microns of material from the bottom of containers.

The methods employed are varied, and often very aggressive; or, they are as simple as just soaking the container. Nonetheless, nothing can properly scrub a container as thoroughly as broom bristles can.

Bottle brushes clean hygienically. Evidence of the benefit of employing bottle brushes is how effectively and completely the interior of the bottle or container is cleaned.

There is a bottle brush to fulfill the cleaning requirements of any container, with bristles capable of wiping any and all dried-on, stuck on, oily residue’s and other contaminants.

Bristles on bottle brushes are chemically resistant, and stiff enough to wipe away any potential material.

Thorough and complete cleaning is critical for effective disinfection and decontamination of containers, especially when working in the pharmaceutical and food industries.

In the pharmaceutical industry, cleaning must meet specific cleaning standards before a container can even come into contact with anything for the first time.

Bottle brushes are essential cleaning tools used in both household kitchens and commercial use, for example, in industrial settings. Despite being simple in design, they have the strength and ability to clean thoroughly and effectively.

Application Of Bottle Brushes

Bottle brushes are now required tools for many cleaning operations, for example, as improbable as it may seem, removing debris in pipes and cylinders, and cleaning glasses, containers, and bottles in restaurants.

Initially intended for washing bottles, bottle brushes have lain unclaimed by a range of other cleaning functions.

If it is simply a hard to clean surface or a difficult to clean spot, such as places bacteria, contaminants, and particles may accumulate, then bottle brushes are the tools to use, and out perform other cleaning tools.

Bottle brushes are specifically designed for gaining access and cleaning locations that most brushes cannot reach, let alone clean.

Tube Cleaning

Bottle brushes that can clean too short pipes, and hard to reach spots on machinery. These bottles (and other circular-handled brushes) have a flexible handle enabling placement into tight spaces and difficult to reach locations.

The diameter of the bristles for cleaning round pipe has to be large enough to reach the edge of the pipe, but small enough to allow entry into the tube with minimal resistance.

Drain Cleaning

Drain cleaning brushes are designed with long flexible handles so that drainage cleaning can still take place around bends and curves in pipe collecting debris and clogs. Drain cleaning brushes are intended to work without chemical for the most part.

To maneuver through the bends, twice the required amount of durable bristles are needed due to a larger volume of water moving through.

Valve Cleaning

For valve cleaning, bottle brushes must have very stiff and durable bristles. There are narrower valve’s than are easier to clean than others, and in this case, the hard bristles help to navigate back and forth to remove tough, accumulated residues.

Since solvents and other cleaners are used to clean valves, the bristles also need to be soft enough in order to hold into dust with the cleaning solution, while being stiff and hard enough to release stubborn bristles.

Pipe Cleaning

Pipe cleaning can be performed with a variety of different types of available bottle brushes if the bristles are appropriate. While we think of this as pipe cleaning, it also applies to cleaning other pipe-like fixtures such as outlets and drains of large tanks.

Pipe cleaning, like valve cleaning, will often incorporate the use of solvents and cleaners. However, the bristles for pipe cleaning may not need to be as soft and flexible as the bristles used for valve cleaning. Pipe cleaning bristles can usually be more rigid to match the type of cleaning task.

Test Tube Cleaning

Cleaning test tubes may be a more common application of bottle brushes, specially made brush assembly. They are designed specifically for cleaning test tubes and beakers as well as graduated cylinders.

Bottle Cleaning

Bottle brushes are often used to clean many types of containers such as bottles. In commercial kitchens, they are used for cleaning and sanitizing bottles and other types of narrow containers.

They are flexible enough to thoroughly clean and reach whatever the opening size may be and reach the top, sides and bottoms of bottles.