Welding is a practice with deep roots in history and remains essential in modern manufacturing. There are several welding techniques, and the specific requirements of a project usually dictate which method is chosen. Among these various techniques, tack welding stands out as particularly significant.

If you’re curious about tack welding—what it involves and why it matters—read on. In the following sections, we’ll explore the fundamentals of tack welding and highlight key details that anyone interested in welding should know.

What Is a Tack Weld?

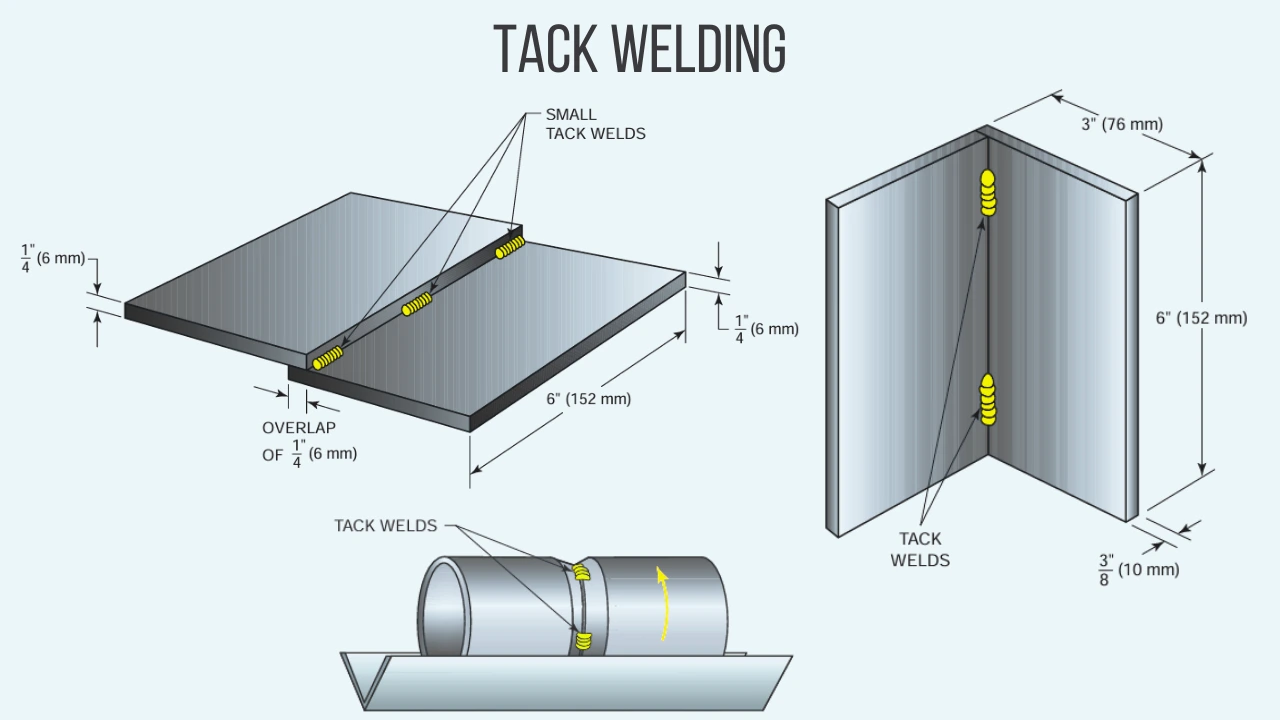

Tack welds are basically those little, temporary welds you use to hold metal parts in position before you go in for the final, proper weld. The nice thing about using tack welds is that they often make clamps or other holding fixtures unnecessary, which can really streamline your workflow. They’re there to make sure everything stays lined up just right, and that the gaps between your metal pieces are exactly where you want them.

Getting your tack welds right is honestly one of the most important steps when you’re assembling parts. You want them to be sturdy enough to keep everything secure for the main weld, but not so bulky that they mess up the shape or look of your finished joint. In other words, your tack welds should blend in seamlessly once the final weld is done—they shouldn’t stand out or cause any weird bumps or irregularities.

It’s also worth mentioning that you can’t just throw in a few tack welds randomly and hope for the best. You actually need to think ahead about how many you’ll use, where you’ll put them, and how big they should be. A little planning goes a long way to make sure your final result is both strong and neat.

Things To Consider While Making a Tack Welds

Some of the factors to consider regarding the number of tack welds include the following:

- Thickness of the Metal: When working with thin metal, it’s generally best to apply numerous small tack welds. This approach helps prevent distortion and maintains structural integrity. On the other hand, with thicker materials, you can usually rely on fewer but larger tack welds, since the metal can handle more heat without warping.

- Length and Shape of the Joint: The joint’s length and configuration also play a significant role in determining tack weld placement. Short joints usually only need a handful of welds. However, the story changes with longer joints: sometimes, a long, straight seam will require surprisingly few tack welds, while a shorter but more curved joint could demand extra attention to maintain alignment throughout its complex shape.

- Welding Stresses: It’s important to remember that every weld introduces stress as the metal cools and contracts. Bigger welds tend to create more significant stress, which can be enough to tear weak tack welds away from adjoining parts. For this reason, tack welds need to be robust enough to withstand the pulling forces generated during the main welding process.

- Tolerances: Precision requirements, or tolerances, also affect how many tack welds you’ll need. The stricter the tolerance for the final welded piece, the more tack welds are generally required. This ensures that everything stays exactly where it should during welding, preventing unwanted shifts.

- Fit-Up: Finally, when you’re fitting parts together especially if you have to custom-bend pieces as you go a greater number of small tack welds can help. These extra welds keep everything in alignment and make it much easier to achieve consistent, even bends throughout the workpiece.

When making tack welds, it’s important to follow a suitable welding procedure and choose the correct filler metal for the job. The placement of these tack welds should be well within the joint, ensuring they’ll be fully remelted into the final weld. This approach helps maintain the integrity of the weld without leaving behind any weak spots.

After the tack welds are applied, don’t skip the cleanup. Removing slag and any lingering impurities is essential; otherwise, you risk introducing flaws into the finished weld. In some cases, you may find it necessary to grind the ends of a tack weld into a taper—this helps the final weld tie in smoothly and avoids those unsightly bumps or irregularities.

One thing to always keep in mind: a proper tack weld does its job by holding everything in place but becomes invisible once the final weld is complete. If you can spot your tack weld in the finished piece, something probably went wrong along the way.

Now, the behavior of tack welds can vary depending on the type of metal you’re working with. On tougher metals like steel, you might actually hear the tack weld snap if it fails—anything from a quick, sharp sound to a deep thud, depending on the material’s size and thickness. On the other hand, with softer metals like aluminum, a tack weld might break with barely a sound.

Whether you notice a tack weld breaking while you’re welding or after you’ve finished, don’t ignore it. It’s a red flag. Continuing to weld with a broken tack can allow the parts to move out of alignment, making it almost impossible to pull everything back into place later. If that happens, your project may no longer meet the required specs—in other words, you end up with scrap metal, not a proper weldment.

Types of Tack Welding

Welders utilize several distinct types of tack welding, each designed for specific applications and objectives. In this section, we will examine the five most widely used methods and discuss the situations in which each is most effective.

Standard Tack Weld

In typical welding practice, tack welds are placed directly inside the joint, with the purpose of being incorporated into the final weld itself. Their main role is to keep the workpieces properly aligned and secure while the main welding process is carried out.

Bridge Tack Weld

Sometimes, during the fit-up process, a gap might be left that needs to be filled with weld. In these cases, welders often use a bridge tack across the gap. These kinds of gaps usually happen when the material has been cut a little too short in the shop, or sometimes the pieces arrive from the supplier already a bit distorted.

One common approach to dealing with this is to use a sweeping motion with the welder to bridge the gap. It’s important to avoid laying down too much weld material at once because excessive heat can cause the weld pool to drop right through the gap. To keep things under control, it’s a good idea to make quick passes and let the area cool slightly between each one.

There’s another method, too: you can place small tack welds on each side of the gap, switching from side to side and giving each tack a chance to cool before adding the next. By gradually working toward the center, you’ll eventually close the gap and tie both sides of the joint together.

Although this technique does take more time—especially with MIG or flux-cored welding—it can be quite effective. Just keep in mind that these bridge tacks don’t actually penetrate all the way to the root of the joint. Once you’ve completed your first root pass, you’ll need to grind them off.

Thermit Tack

The thermit tack process requires combining pure magnesium metal with aluminum and iron oxide powders. When these components react, the resulting chemical reaction generates extremely high temperatures—often exceeding 4,000 degrees Fahrenheit.

Hot Tacking

A hot tack weld is created by intentionally adding extra filler metal into the space between two metal pieces. Once the filler has been applied, the gap is physically closed by striking it with a hammer.

These hot tacks are often referred to as “cleats” or “dogs” in the field. Although this approach can be both fast and practical for closing gaps during fabrication, it generally does not meet the rigorous standards set by quality control. As a result, items assembled using this method rarely pass formal inspection.

Ultrasonic Tack

Ultrasonic tack welding is a process where a welder uses an electric or gas welding machine to join materials together. What sets this method apart is the way it generates a series of quick, short bursts either pushes or pulls that travel through the components being welded at ultrasonic speeds. This rapid movement helps to create the necessary conditions for welding.

During the process, the welder applies the welding wire with enough pressure into the base metal so that the intense friction and force generate heat, melting the material right at the contact point. As the material becomes molten, it fuses the separate parts into a single, solid piece.

Four Forms of Tack Welds

The forms of tack welds help hold parts together before full welding. They also help attach parts. There are four main forms.

- Square Tack Weld: This technique offers significant strength by arranging tack welds in a square pattern. It is particularly well-suited for situations where two components need to be joined at a right angle, ensuring both stability and precise alignment.

- Vertical Tack Weld: With the vertical method, the tack weld is applied in a straight line from the top to the bottom of the metal pieces. This approach is effective when you need to keep two parts aligned vertically often, the weld is started at the upper edge to maintain evenness throughout the joint.

- Right Angle Tack Weld: This tack weld is specifically designed for joining two pieces of metal that meet perpendicularly. For example, when the aim is to secure two components at a right angle, applying the tack to the lower piece provides the necessary stability during assembly.

- Right Angle Corner Tack Weld: When two pieces are joined perpendicularly to create a T-shaped joint, the right-angle corner tack is the most effective. The weld is made precisely at the 90-degree intersection, ensuring that the connection remains robust and properly aligned.

The Pros and Cons of Tack Welding

Advantages Of Tack Welding

- Temporary welds play a crucial role in holding different parts together, ensuring the joint maintains its intended geometry during assembly.

- One key advantage is that they allow for quick and straightforward disassembly when adjustments or rework are necessary.

- This method makes it possible to weld components without relying on large, cumbersome fixtures, which can be especially beneficial in smaller workspaces.

- Tack welding also simplifies the process of keeping joints aligned, particularly in areas where space is limited and maneuverability is a challenge.

- It’s effective at setting and maintaining the desired gap between pieces, which is essential for achieving a quality final weld.

- Additionally, tack welds provide enough mechanical strength to support the weight of the base metal if the assembly needs to be repositioned or moved.

- By temporarily stabilizing parts, tack welding helps reduce the risk of distortion that can occur during the main welding process.

- Once you’re familiar with the common pitfalls and know how to avoid them, tack welding becomes a relatively straightforward technique.

- Finally, this approach is quite versatile—you can apply tack welds to almost any type of material.

Disadvantages of Tack Welding

- The bonds created by tack welding are only temporary and generally not very strong.

- If the tack welding process isn’t done properly, it can actually reduce the overall quality of the finished joint.

- One drawback is that tack welding tends to increase the formation of oxides during the process.

- After tack welding, there’s usually some cleaning up to do, as residues or oxides can build up on the welded parts.

- When working with certain materials especially steels that are hard and brittle it takes real expertise. Without the right know-how, the tack welds can make the area more susceptible to cracking.

- Some metals just don’t cope well with the quick, concentrated heating and cooling that tack welding involves, which can lead to additional issues.

- It’s also worth noting that tack welding becomes much trickier when dealing with large components or working close to the edges of parts..

Wrapping It

When you’re getting ready to weld two pieces of metal together, tack welding comes in handy as a way to temporarily hold everything in place before you commit to the final weld. Basically, these quick little welds act like extra hands, making sure your pieces stay exactly where you want them—so the alignment, gap, and angle are all spot on.

Tack welds do more than just hold things steady, though. They also help keep the metal from warping or shifting as you finish the main weld, which can sometimes save you the trouble of setting up bulky fixtures. That’s especially helpful if you’re only doing a few pieces or working on a one-off project where it’s not really worth investing in special equipment.

Even though tack welds are meant to be small and easy to remove, they still have to be sturdy enough to do the job without messing up the base material. It’s a balancing act—strong enough to keep everything locked in, but not so big that they cause problems later on.

FAQs

What is a Tack Weld

Tack welding is a temporary welding process that involves using low heat and a very short arc to weld metal pieces together before the final welding. It helps ease the process of welding as it ensures metal parts do not move before the completion of the sheet metal welding process.

Can tack welding be permanent?

While tack welding shouldn’t be considered a permanent method of joining sheet metal and other materials, there are several advantages to using this method as part of the process.

What is the difference between tack and full welding?

Tack welding forms a temporary pre-weld, whereas spot welding is a method used to fuse two metals together permanently. Tack welding uses filler material when joining metal pieces, whereas spot welding is carried out through a combination of electrical current and pressure being applied to the metals being fused.

What kind of welder do you use for tack welds?

Another method is to apply small tacks to each side, alternating to allow the other side to cool. Eventually, you will reach the middle of the gap and join both joint sides. This method is more time-consuming and works best with MIG or flux-cored welding.

What is tack welding disadvantages?

It’s temporary and produces weak bonds. Joint quality can be impaired if tack welding isn’t carried out correctly. It exacerbates the build-up of oxides. Parts will need to be cleaned afterward.

What is the toughest weld?

TIG welding is often considered the strongest weld since it produces extreme heat, and the slow cooling rate results in high tensile strength and ductility. MIG is also an excellent candidate for the strongest type of weld because it can create a strong joint.