What is a Pulley?

A pulley is essentially a wheel designed to support the movement of a flexible element—such as a rope, cable, cord, belt, or even a chain—along its rim. Whether used on its own or as part of a larger system, a pulley’s primary role is to facilitate the transfer of motion and power.

When the pulley has a grooved rim, it is specifically referred to as a sheave. In mechanical systems like belt drives, pulleys are typically mounted on shafts via their axles, allowing continuous belts to loop over them and transmit power between rotating shafts.

One of the most practical uses of pulleys is in lifting heavy objects, especially when multiple pulleys are configured together. This setup can significantly reduce the amount of force required, creating what’s known as a mechanical advantage.

Such arrangements are often referred to as a block and tackle, which has long been used to multiply force in lifting and hoisting operations. Beyond lifting, pulleys are integral to many belt and chain drive systems that connect rotating machinery, ensuring efficient transmission of power across components.

Historically, the significance of pulleys isn’t just mechanical but also quite fascinating. The Greek mathematician Archimedes, who lived during the 3rd century BCE, is famously credited with employing compound pulleys to haul a ship out of the water and onto land.

This wasn’t just theoretical—according to historical accounts, it actually happened. In fact, Plutarch, in his Parallel Lives, describes an instance where Archimedes used a compound pulley system to effortlessly pull a fully loaded ship toward himself, as though it were gliding on calm seas.

Further testament to the early understanding of pulley systems can be found in the writings of Hero of Alexandria, a scholar and inventor from Roman Egypt.

Around 10 to 70 CE, Hero identified the pulley as one of the six fundamental simple machines used to lift weights, placing it alongside tools like the lever and the screw in the foundational toolkit of classical mechanics.

Now, when the pulley is held in place by a frame or housing that doesn’t actually transmit power to the shaft—but instead serves to guide the cable or apply force—that outer structure is known as a block. In such cases, the pulley itself is often referred to as a sheave.

What Are the Uses Of Pulleys?

Pulleys were originally developed to simplify the task of lifting heavy objects. At their core, pulleys are simple machines that consist of a wheel paired with a rope, cord, or chain looped around it.

Today, pulleys are widely used in various settings to ease the effort required for many tasks. Beyond just lifting, pulleys—whether used individually or in systems with multiple wheels—can help move objects or even people from one place to another. They also play a crucial role in mechanical systems by transmitting power between rotating shafts.

Examples Of Pulleys In Everyday Life

Examples of pulleys include:

- Elevators: Modern elevators rely on a sophisticated electronic pulley mechanism to operate. This setup typically includes multiple pulleys and counterweights that work together to ensure the elevator moves smoothly while maintaining a high standard of safety.

- Traditional Wells: Old-fashioned water wells—like the ones we often picture from fairy tales—use a simple pulley system to draw water. By turning a crank or pulling on a rope, users can lift a bucket of water with minimal effort.

- Exercise Machines: Many strength-training machines found in gyms incorporate pulleys to help guide and control how weights are lifted. This design not only stabilizes the movement but also reduces the risk of injury, especially for people who may not have perfect form when using free weights.

- Construction Equipment: On construction sites, pulley systems are frequently used to lift materials. These typically involve a wheel-and-rope setup mounted on a tall frame, allowing heavy loads to be raised safely and efficiently. They’re a great example of how simple mechanics can solve real-world challenges.

- Theater Rigging Systems: If you’ve ever wondered how stage curtains and scenery seem to glide up and down so seamlessly during a theater performance—it’s thanks to a hidden system of pulleys. These are usually installed high above the stage and operated discreetly from the wings to avoid drawing the audience’s attention.

- Cargo Lifts: In multi-story buildings or warehouses, pulley-based cargo lift systems are used to move heavy items between floors. These systems reduce the physical strain on workers and streamline the transportation of goods.

- Window Blinds: That cord you pull to adjust your blinds? It’s connected to a compact pulley system that raises or lowers the slats. It’s a simple design, but it’s a perfect example of pulleys making everyday tasks easier.

- Flagpoles: Raising or lowering a flag might seem straightforward, but it’s made possible through a pulley system. Pulling on the rope rotates the pulley and moves the flag up or down the pole with ease.

- Heavy Machinery: Machines like cranes, bulldozers, and even escalators rely heavily on pulley systems to perform lifting and movement functions. These systems multiply force, allowing the machines to handle massive weights with precision and control.

- Various Tools and Equipment: Pulleys show up in more places than you might expect: garage doors, sailboats, car engines, extension ladders, and even in the gear used by rock climbers. In all of these, pulleys make the process smoother, safer, and more efficient.

Pulleys are commonly used in various lifting and moving applications. Essentially, a pulley system helps reduce the effort needed to lift or shift heavy objects.

This mechanical advantage makes pulleys especially valuable when dealing with loads that are too large or heavy to move manually.

Despite their simplicity, pulleys remain one of the most efficient and widely used tools for handling weight, owing to the straightforward yet powerful principles behind their operation.

How do pulleys work?

A pulley is a fundamental type of simple machine made up of a grooved wheel and a rope that fits into the groove. When you pull on the rope, it rotates the wheel, allowing the system to do work. Pulleys are especially useful for lifting objects—particularly heavy ones—and the item being lifted is typically referred to as the load.

One of the key advantages of using a pulley with a single wheel is that it changes the direction of the force you need to apply. For example, instead of lifting an object upward directly, you can pull downward on the rope, making the task feel easier. When you introduce a second wheel into the setup, it reduces the amount of effort needed to lift the same object. Essentially, it cuts the required lifting force in half.

As you increase the number of wheels and wrap the rope around them more times, the mechanical advantage improves even further. This means you’re able to lift heavier loads with less effort, thanks to the way the system distributes force.

A pulley is a type of simple machine that consists of one or more wheels, over which a rope or, in the case of heavier loads, a sturdy chain is looped. What makes pulleys particularly useful is their ability to amplify the force applied by a person, making it significantly easier to lift heavy objects. By incorporating a wheel into the system, the pulley not only allows the force to be redirected—typically enabling the user to pull downward to lift a load upward—but also makes the process more efficient.

When using a basic pulley with a single wheel, you change the direction of the applied force. Instead of lifting directly upward, you can pull downward on the rope to raise the object, which tends to be more manageable and ergonomically favorable.

Introducing a second wheel into the setup creates what’s known as a two-wheel pulley system. This configuration effectively reduces the amount of force required to lift the same weight—cutting the necessary effort in half.

This phenomenon is explained by the concept of Mechanical Advantage. In this case, a two-wheel system provides a mechanical advantage of 2, meaning you exert only half the force that would otherwise be needed.

The principle is straightforward: the greater the mechanical advantage, the less force is required. As more wheels are added, and the rope is looped around multiple times, the lifting process becomes even more efficient.

Systems that employ several wheels and rope wraps are commonly referred to as compound pulley systems. These are particularly valuable in situations where lifting very heavy objects is necessary.

As the rope is pulled, the movement causes the upper and lower sets of wheels (or axes) to gradually draw closer together. This action increases the lifting power of the user, making it possible to raise substantial weights with much less physical strain.

Material Use For Pulleys

Pulleys are manufactured using a range of materials, such as cast iron, cast steel, pressed steel, wood, and even paper. When using cast materials, it is important that they offer reliable friction and resistance to wear, as these properties contribute to their performance and durability.

Pressed steel pulleys, on the other hand, are typically lighter than those made from cast metals. However, this advantage can come at a cost these lighter pulleys often exhibit reduced friction and may lead to increased wear under certain operating conditions.

Types of Pulley

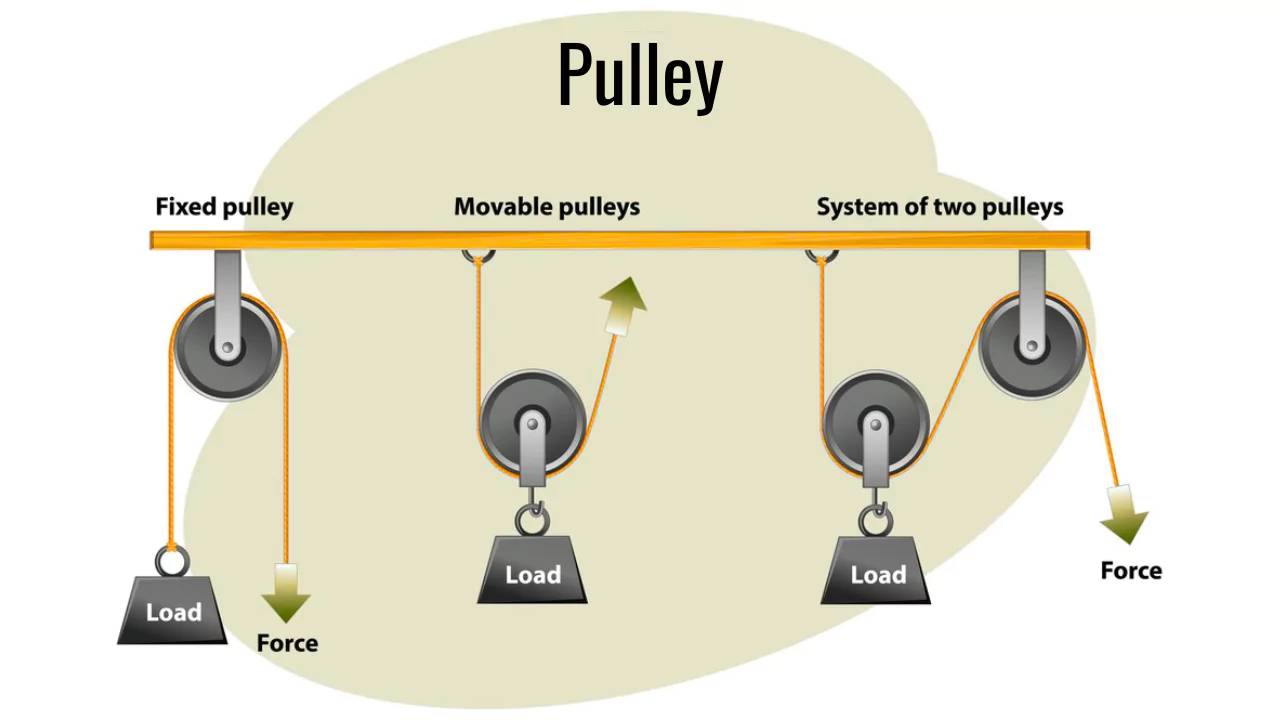

There are three main types of pulleys:

- Fixed pulley.

- Movable pulley.

- Compound Pulley.

- Cone Pulley.

- Block and Tackle pulley.

1. Fixed Pulley

A fixed pulley is a simple machine where the wheel and axle remain anchored in one place. What makes it useful isn’t that it reduces the effort needed, but that it redirects the force applied. A classic example would be a flagpole: when you pull the rope downward, the pulley redirects that force upward, raising the flag smoothly.

In essence, a fixed pulley consists of a drum or wheel secured to a single spot. It doesn’t reduce the amount of force you need lifting something with it requires just as much effort as lifting it by hand but it changes how that effort is applied. That small shift can make a big difference in comfort and practicality.

Think of drawing water from a well. Instead of pulling a heavy bucket straight up with both hands, a pulley lets you pull sideways or downward. The bucket doesn’t weigh any less, but the motion feels more natural and manageable. That’s the key benefit: it gives you better control over your effort without changing the actual load.

2. Movable pulley

A movable pulley is designed with its axle mounted within a movable block, allowing the pulley itself to shift position as the load is lifted. This system is typically supported by two segments of the same rope, providing a mechanical advantage of 2. In practical terms, this means the force required to lift a load is effectively halved.

Unlike fixed pulleys, a movable pulley does not alter the direction of the applied force. Instead, it reduces the amount of force needed to lift the object. So, while you’re still pulling in the same direction—usually upward or downward, depending on the setup—the load feels significantly lighter.

To put it into context, imagine trying to raise a heavy hay bale into a barn loft. Using a movable pulley system in this scenario wouldn’t change the way you pull the rope, but it would noticeably ease the effort required, making the bale seem lighter than it actually is.

3. Compound Pulley

In a compound pulley system, both a fixed pulley and a movable pulley are used together. This combination allows for two main advantages: it reduces the effective weight of the load, making it easier to lift, and it changes the direction of the applied force, which can be more convenient for the person doing the lifting.

However, this added efficiency comes with a tradeoff. While it becomes easier to move heavier objects, you need to pull much more rope to lift the load the same distance. In other words, the effort required feels lighter, but you have to move your hand farther to get the job done.

4. Cone pulley

The cone pulley represents a more specialized adaptation of the traditional pulley system, designed to allow for flexible mechanical adjustments. Structurally, it consists of a series of pulleys stacked in a conical arrangement, each tier featuring a slightly different diameter.

This tapered design gives users the ability to adjust the speed and force involved in operation. By moving the belt to a smaller diameter, less effort is needed to drive the system—but this also results in reduced output. Conversely, shifting to a larger diameter increases the output but demands more effort.

A familiar example of this concept in action is the gear mechanism on multi-speed bicycles. Cyclists can shift between smaller gears, which make pedaling easier but slower, and larger gears, which require more effort but result in more distance covered with each pedal rotation.

5. Block and Tackle pulley

A block and tackle system is a specialized type of compound pulley designed to significantly reduce the effort needed to lift or move heavy objects.

This setup involves a combination of fixed and movable pulleys, typically arranged in parallel. The fixed pulley is anchored in place, while the movable pulleys shift with the load, working together in coordination.

Each pair of pulleys in the system is connected to the next, and as more pairs are added, the amount of effort required continues to decrease. Essentially, every additional set amplifies the mechanical advantage, making the task easier.

Historically, the concept of the block and tackle is credited to Archimedes, the renowned ancient Greek mathematician and inventor, whose contributions laid the foundation for many principles of mechanics still in use today.

Advantages and Disadvantages of Pulley Drive

Advantages of pulley

- One of the biggest benefits of using pulleys is that they make lifting heavy loads much easier—significantly reducing the amount of effort needed compared to lifting the weight directly.

- This system minimizes the actual force a person has to apply, making it possible to move heavy objects with much less strain.

- Another helpful feature of pulleys is that they can change the direction of the force. For example, instead of lifting something straight up, you can pull down to lift it—making the task more manageable.

- By design, pulleys offer what’s called a mechanical advantage, meaning they multiply the input force, allowing users to do more with less.

- Safety is also a major plus. Since the user doesn’t have to be right next to the load, there’s a safer distance between the person operating the pulley and the weight, reducing the risk of accidents.

- On top of that, pulleys are straightforward to set up and don’t cost much, which makes them practical for a wide range of uses.

- And while they do include moving parts, once a pulley system is installed, it generally doesn’t need much maintenance—some systems work smoothly with little to no lubrication.

Disadvantages of pulley

- Since this system relies on friction to transmit motion, there’s always a possibility that slippage can occur during operation.

- It’s generally not the best option when you’re dealing with extremely high power transmission at high rotational speeds it just isn’t built for that kind of load.

- When you try to gain more mechanical advantage, one trade-off is that the lifting distance increases, which can be a limiting factor in certain applications.

- Over time, the rope is susceptible to fatigue and creep, which can eventually lead to failure or breakage, especially under constant load or stress.

- There’s also a tendency for the rope to slip, particularly when it’s pulled off-center or at an angle something that can reduce efficiency and control.

- Trying to directly compare this system with gears isn’t very meaningful, since they operate on fundamentally different principles and serve different mechanical needs.

- In a compound pulley setup, you’ll typically see several wheels and extra rope segments working together to make it easier to lift heavy loads it’s all about distributing the weight more efficiently.

FAQs.

What is a pulley used for?

The pulley, a simple machine, helps to perform work by changing the direction of forces and making easier the moving of large objects. When thinking of pulleys, most people think of the type of pulley that allows a person to redirect the direction of a force.

What is pulley in belt drive?

Belt Pulleys are used for transmitting power from one source to another in a drive mechanism. That generally used roles and gears for pulling and used in automotive engines such as in cars, trucks and buses. There are different types of pulleys based on their speed, power and distance between the shafts.

What is the definition of a simple pulley?

Pulley is a simple machine and comprises of a wheel on a fixed axle, with a groove along the edges to guide a rope or cable. Pulleys are used to reduce the time and energy taken to lift heavy objects. Here, Load = the weight of an object Effort = the amount of force required to lift or move this object.

What happens when belt pulley goes bad?

When pulleys wear out, they often struggle to maintain tension on the belt. As a result, the belt can come loose and knock against other components, causing a slapping-like noise. In most cases, this is an indication that you will need a new pulley, and perhaps even a new belt, depending on the damage caused.

What pulley does the serpentine belt go on?

The serpentine belt, driven by the crankshaft pulley, is connected to the engine. From there, it wraps around multiple other pulleys that power different components in the engine, such as the alternator, air conditioning compressor, power steering pump, and water pump.